Installation manual

15

EMRQ8~16ABY1

Daikin Altherma outdoor unit

4P501819-1 – 2017.08

5

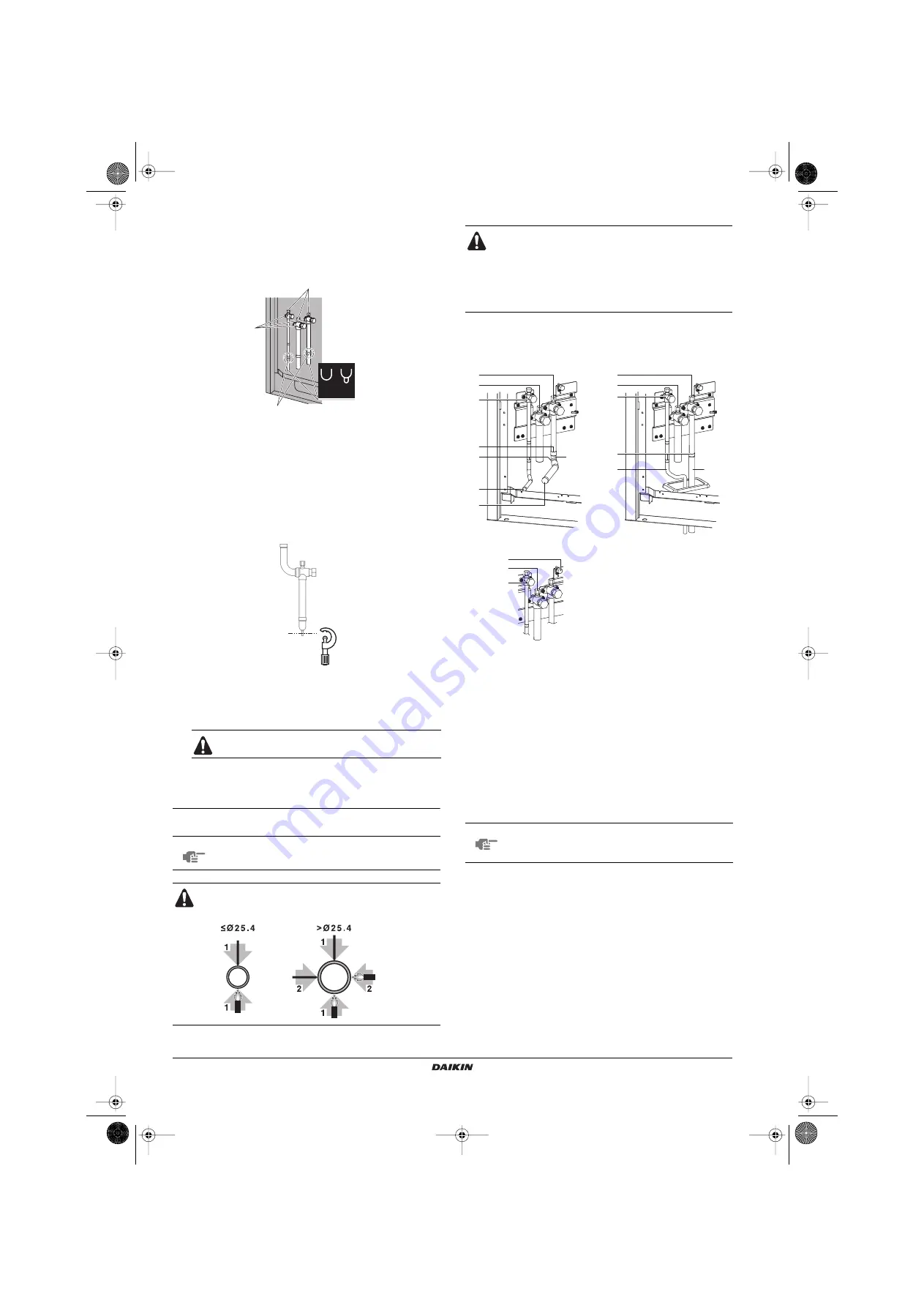

In case the pinched piping lower part looks like detail A in the

figure below, follow instructions as per procedure steps

.

In case the pinched piping lower part looks like detail B in the

figure below, follow instructions as per procedure steps

-

6

For the discharge gas stop valve, cut off the lower part of the

smaller pinched piping with an appropriate tool (e.g. pipe cutter,

a pair of nippers, …). Let the remaining oil drip out in case the

recovery was not complete:

Wait until all oil is dripped out.

7

Cut the pinched piping of the liquid pipe and discharge gas pipe

stop valve off with a pipe cutter just above the brazing point or

marking if there is no brazing point.

8

Wait until all oil is dripped out before continuing with the

connection of the field piping in case the recovery was not

complete.

3.

Connecting refrigerant piping to the outdoor unit.

Connection from the stop valves to the field piping using accessory

pipes should be as below:

The connections above to the branch kits, are the responsibility of the

installer (field piping).

1

Pinched piping

2

Stop valve

3

Service port

4

Point of melting the brazing metal; cut pipe off just above this

brazing or marking point

Never remove the pinched piping by brazing.

NOTE

All local interunit piping are field supplied except

the accessory pipes.

Precautions when connecting field piping.

Add brazing material as shown in the figure.

B

A

3

2

4

1

■

Be sure to use the supplied accessory pipes when

carrying out piping work in the field.

■

Be sure that the field installed piping does not touch

other pipes, the bottom panel or side panel. Especially

for the bottom and side connection, be sure to protect

the piping with suitable insulation, to prevent it from

coming into contact with the casing.

A

Front connection

B

Bottom connection

C

EMRQ8

1

Liquid pipe stop valve

2

Suction gas pipe stop valve (not used)

3

Discharge gas pipe stop valve

4

Brazing

5

Liquid accessory pipe (1)

6

Discharge gas accessory pipe (1)

7

Accessory joint (angle 90°) (2)

8

Liquid accessory pipe (2)

9

Discharge gas accessory pipe (2)

NOTE

Make sure that the onsite piping does not come in

contact with other piping, the bottom frame or side

panels of the unit.

A

B

C

1

2

7

4

4

3

1

2

2

3

6

5

4

8

9

1

3

4PEN501819-1.book Page 15 Wednesday, September 13, 2017 12:52 PM