D

–EIMAC00708-16EN - 65/76

Routine maintenance

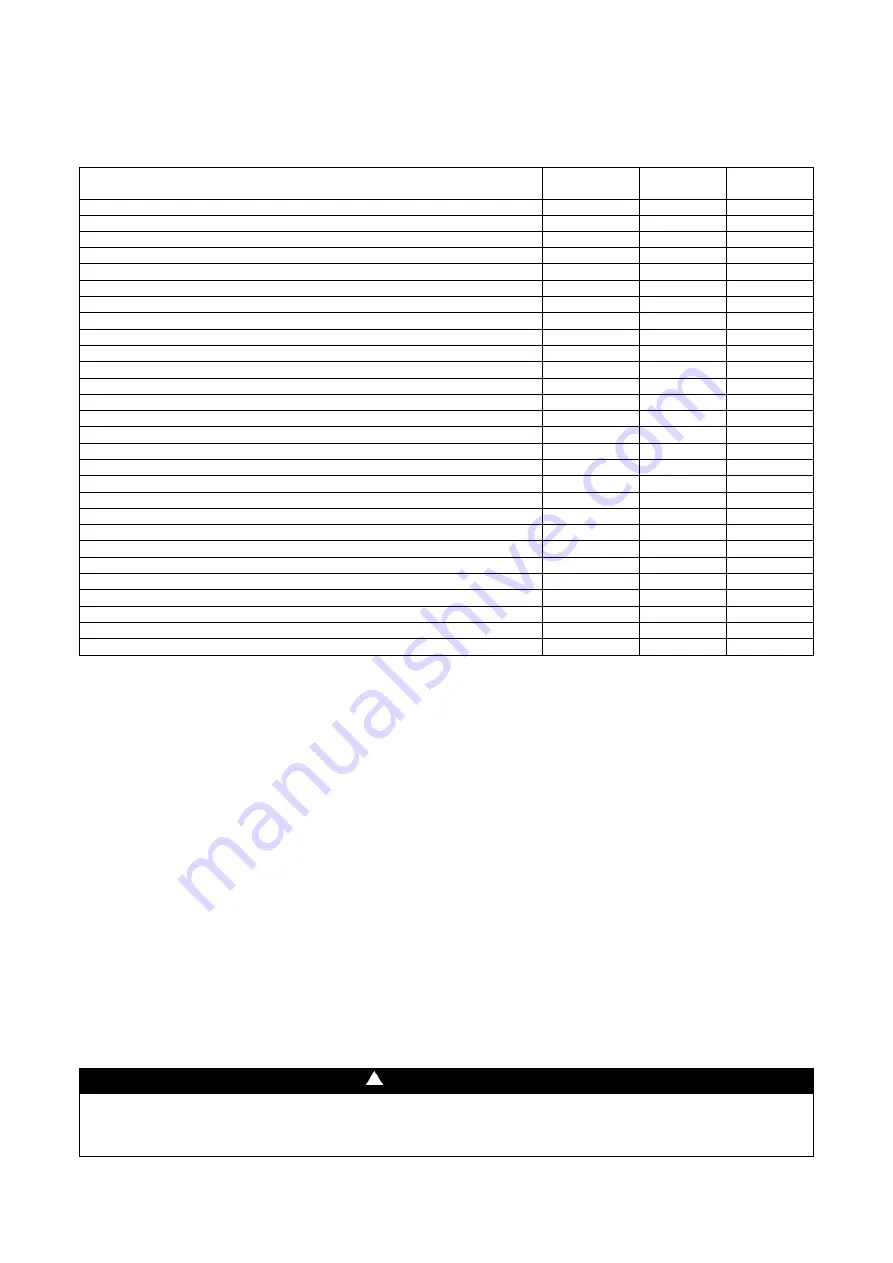

Table 26 - Routine maintenance programme

List of Activities

Weekly

Monthly

(Note 1)

Yearly

(Note 2)

General:

Collection of operating data (Note 3)

X

Visual inspection of machine for any damage and/or loosening

X

Verification of thermal insulation integrity

X

Clean and paint where necessary

X

Analysis of water (6)

X

Electrical:

Verification of control sequence

X

Verify contactor wear

– Replace if necessary

X

Verify that all electrical terminals are tightened

– Tighten if necessary

X

Clean inside the electrical control board

X

Visual inspection of components for any signs of overheating

X

Verify operation of compressor and of its electrical resistance

X

Measure compressor engine isolation using the Megger

X

Chilling circuit:

Test for any refrigerant leakage

X

Verify refrigerant flow using the liquid pilot lamp

– Pilot lamp full

X

Verify dehydration filter pressure drop

X

Verify oil filter pressure drop (Note 5)

X

Analyse compressor vibrations

X

Analyse compressor oil acidity (7)

X

Condenser section:

Clean condenser batteries (Note 4)

X

Verify that ventilators are well tightened

X

Verify battery fins

– Comb if necessary

X

Notes:

1)

Monthly activities include all the weekly ones

2)

The annual (or early season) activities include all weekly and monthly activities

3)

Machine operating values should be noted daily thus keeping the observation level high.

4)

Battery cleaning could be more frequently necessary in environments with a high percentage of particles in the

air.

5)

Replace the oil filter when its pressure drop reaches 2.0 bars

6)

Check for any dissolved metals

7)

TAN (Total Acid Number) :

0.10 : No action

Between 0.10 and 0.19 : Replacement of anti-acid filters

and verification after 1000 hours’ operation. Continue

substituting filters until the TAN falls below 0.10.

0.19 : Replace oil, oil filter and dehydration filter. Verify at regular intervals.

Dehydration filter replacement

It is strongly advised that the dehydration filter cartridges be replaced in the event of a considerable pressure drop across

the filter itself or of a passage of bubbles through the liquid pilot lamp while the undercooling value is within the accepted

limits.

Replacement of the cartridges is advised when the pressure drop across the filter reaches 50 kPa with the compressor

under full load.

The cartridges must also be replaced when the humidity indicator inside the liquid pilot lamp changes color and shows

excessive humidity, or when the periodic oil test reveals the presence of acidity (TAN is too high)

Dehydration filter cartridge replacement procedure

ATTENTION

Ensure proper water flow through the evaporator during the entire servicing period. Interrupting the water flow during this

procedure would cause the evaporator to freeze, with consequent breakage of internal piping.