Installation manual

7

ERQ100~140A7V1B

Inverter condensing unit

4PW51321-1

8.1.

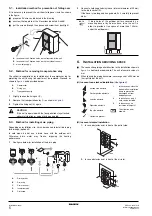

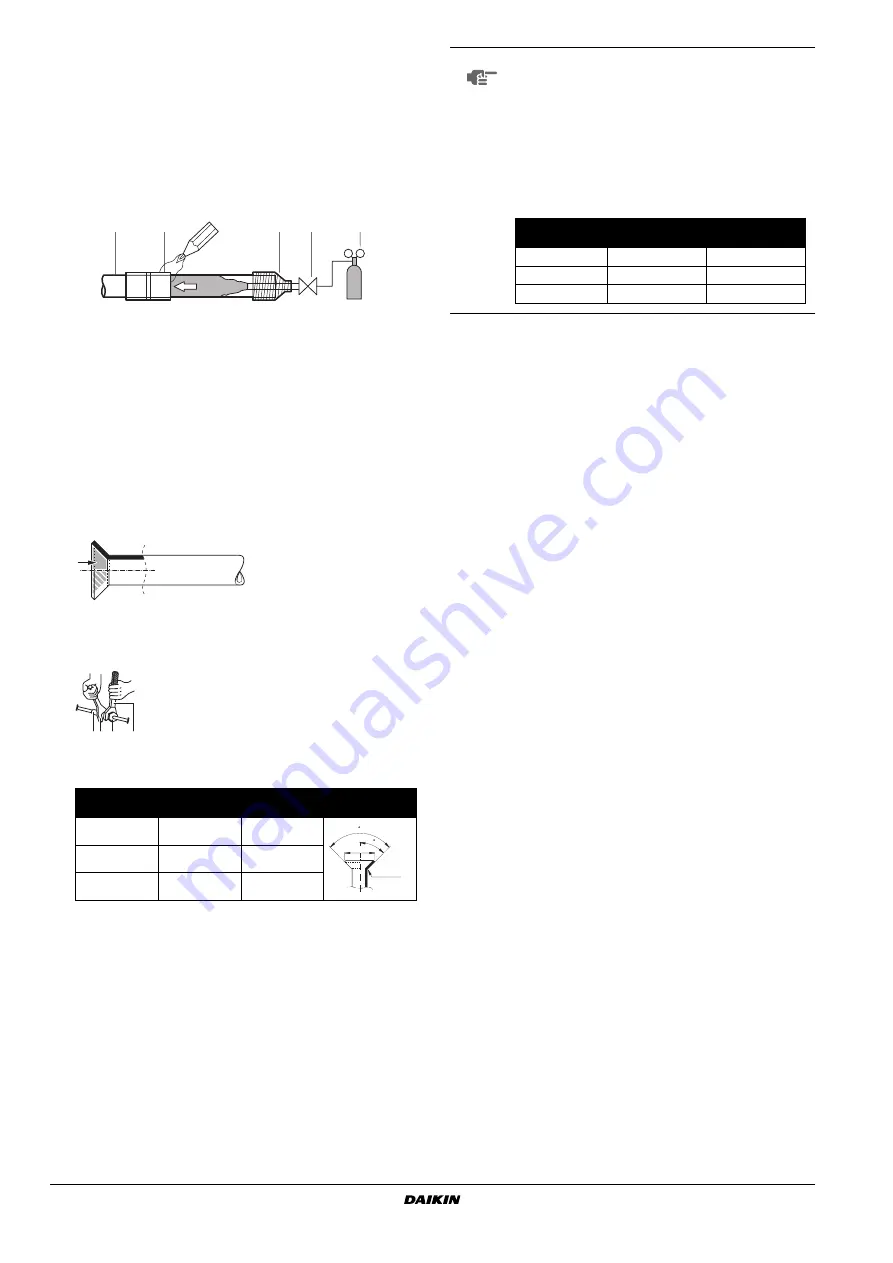

Cautions for brazing

■

Be sure to carry out a nitrogen blow when brazing.

Brazing without carrying out nitrogen replacement or releasing

nitrogen into the piping will create large quantities of oxidized

film on the inside of the pipes, adversely affecting valves and

compressors in the refrigerating system and preventing normal

operation.

■

When brazing while inserting nitrogen into the piping, nitrogen

must be set to 0.02 MPa with a pressure-reducing valve (=just

enough so that it can be felt on the skin).

8.2.

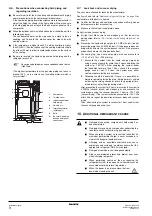

Cautions for flare connection

■

See the following table for flare part machining dimensions.

■

When connecting the flare nut, coat the flare inner surface with

ether oil or ester oil and initially tighten 3 or 4 turns by hand

before tightening firmly.

■

When loosening a flare nut, always use two wrenches in

combination. When connecting the piping, always use a spanner

and torque wrench in combination to tighten the flare nut.

■

See the following table for tightening torque.

(Applying too much torque may cause the flares to crack.)

■

After all the piping has been connected, use nitrogen to perform

a gas leak check.

9.

R

EFRIGERANT

PIPING

■

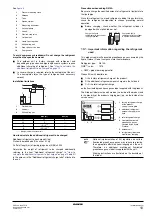

Field pipes can be installed in four directions.

Figure - Field pipes in four directions

When connecting the piping in the lateral direction (on the rear),

remove the piping cover (rear) in reference to

■

To install the connecting pipe to the unit in a downward direction,

make a knockout hole by penetrating the center area around the

knockout hole using a Ø6 mm drill.

■

Cutting out the two slits makes it possible to install as shown in

(Use a metal saw to cut out the slits.)

■

After knocking out the knock-out, it is recommended to apply

repair paint to the edge and the surrounding end surfaces to

prevent rusting.

1

Refrigerant piping

2

Part to be brazed

3

Taping

4

Hands valve

5

Pressure-reducing valve

6

Nitrogen

Pipe size

Tightening

torque (N•m)

A (mm)

Flare shape

Ø9.5

33~39 N•m

12.8~13.2

Ø15.9

63~75 N•m

19.3~19.7

Ø19.1

98~110 N•m

12.3~23.7

1

2

3

4

5

6

6

12 3

4

1

Piping union

2

Spanner

3

Flare nut

4

Torque wrench

R=0.4~0.8

45

±

2

90

±

2

A

NOTE

You must use a torque wrench but if you are obliged to

install the unit without a torque wrench, you may follow

the installation method mentioned below.

After the work is finished, make sure to check that

there is no gas leak.

When you keep on tightening the flare nut with a

spanner, there is a point where the tightening torque

suddenly increases. From that position, further tighten

the flare nut within the angle shown below:

1

Drill

2

Center area around knockout hole

3

Knockout hole

4

Slit

5

Connecting pipe liquid (field supply)

6

Bottom frame

7

Front plate

8

Pipe outlet plate

9

Screw front plate

10

Pipe outlet plate screw

11

Connecting pipe gas (field supply, except ERQ250)

A

Forward

B

Backward

C

Sideways

D

Downward

1

Piping cover (rear)

Pipe size

Further tightening

angle

Recommended

arm length of tool

Ø9.5 (3/8")

60~90°

±200 mm

Ø15.9 (5/8")

30~60°

±300 mm

Ø19.1 (5/8")

20~35°

±450 mm