Installation manual

13

ERQ100~140A7V1B

Inverter condensing unit

4PW51321-1

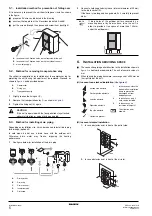

11.3. Connection example of total system wiring

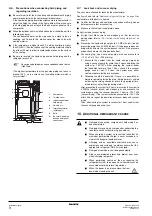

11.4. Connecting power wire and transmission wires

■

Let the power wire (including ground wire) go through the power

outlet port on either the front, side or back of the outdoor unit.

■

Let the transmission wires go through the cable outlet port, pipe

outlet port or knock out hole on either the front, side or back of

the outdoor unit.

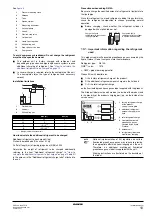

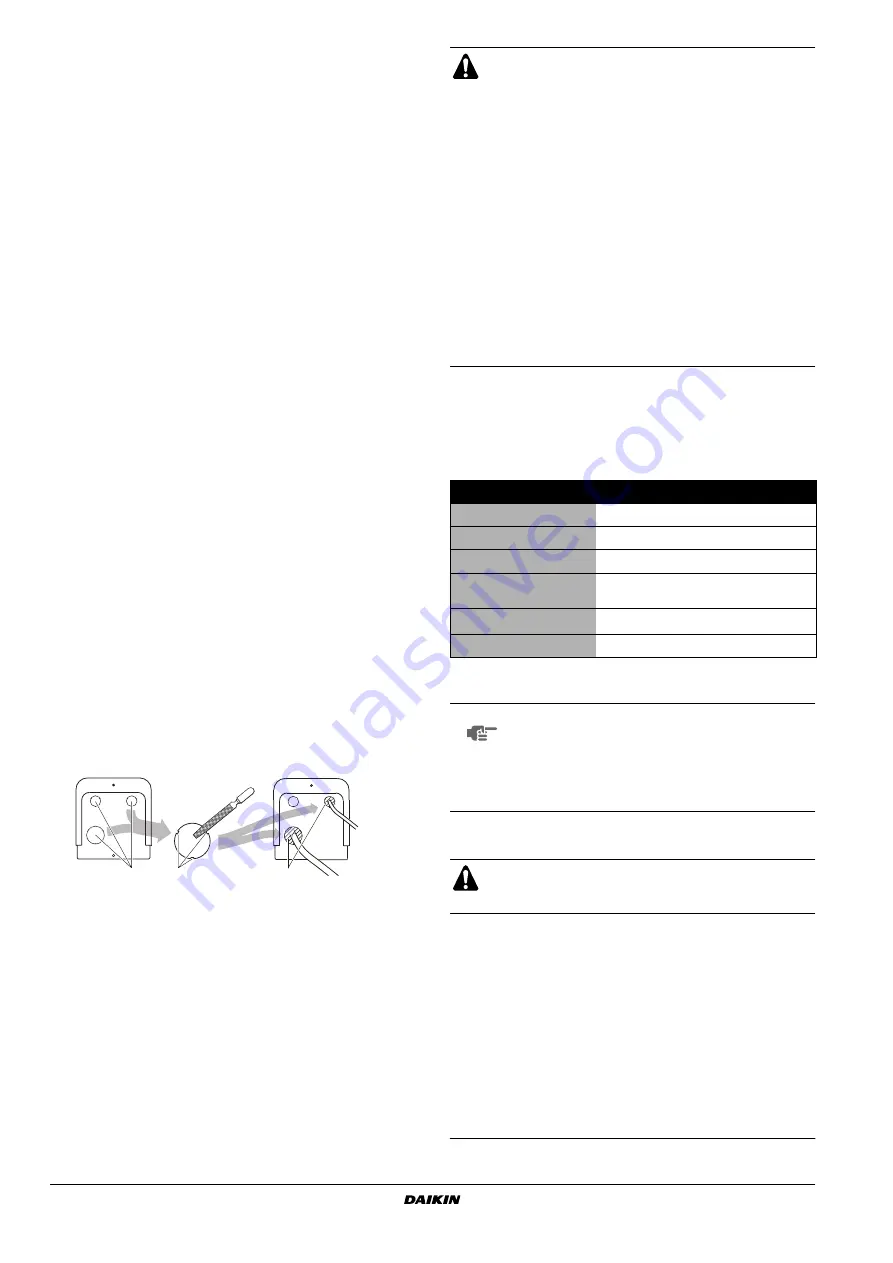

Precautions when knocking out knockout holes

■

To punch a knock hole, hit on it with a hammer.

■

After knocking out the holes, we recommend you paint the

edges and areas around the edges using the repair paint to

prevent rusting.

■

When passing electrical wiring through the knock holes, remove

any burrs from the knock holes and wrap the wiring with

protective tape to prevent damage.

■

If there is any possibility that small animals enter the system

through the knock holes, plug the holes with packing materials

(to be prepared on-site).

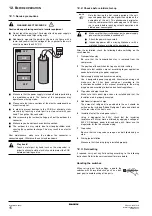

11.5. Power circuit and cable requirements

A power circuit (see table below) must be provided for connection of

the unit. This circuit must be protected with the required safety

devices, i.e. a main switch, a slow blow fuse on each phase and an

earth leakage breaker.

■

In connecting the power cable to the power terminal block,

securely clamp the cable as shown in

Equipment complying with EN/IEC 61000-3-12

(1)

.

1

Power

2

Earth leakage breaker

3

Branch switch overcurrent breaker (fuse)

4

Ground

5

Communication wiring

6

Control box

A

Rear direction

B

Lateral direction

C

Front direction

1

Power terminal block (X1M)

2

Control wiring between units

3

Power cable with ground wire. (Keep proper distance between

power cable and control wiring).

4

Clamp (field supply)

5

Stop valve mounting plate

6

Power cable

7

Ground cable (yellow/green)

8

Fix the control wiring with the clamp

9

Control terminal block (X2M)

1

Knockout hole

2

Burr

3

Packing materials

2

3

1

■

Use a power wire pipe for the power wiring.

■

Outside the unit, make sure the low voltage electric

wiring (i.e. for the remote control, between units, etc.)

and the high voltage electric wiring do not pass near

each other, keeping them at least 50 mm apart.

Proximity may cause electrical interference,

malfunctions, and breakage.

■

Be sure to connect the power wiring to the power

wiring terminal block and secure it as described under

"11.4. Connecting power wire and transmission wires"

on page 13

■

Inter-unit wiring should be secured as described in

"11.4. Connecting power wire and transmission wires"

on page 13

■

Secure the wiring with clamps so that it does not

touch the piping.

■

Make sure the wiring and the electric box lid do not

stick up above the structure, and close the cover

firmly.

ERQ100~140

Phase and frequency

1~ 50 Hz

Voltage

220-240 V

Recommended field fuse

32 A

Minimum circuit amps

(MCA)

(*)

(*)

Stated values are maximum values.

27

Transmission line section

0.75~1.25 mm

2

Wire type

(†)

(†) Only in protected pipes, use H07RN-F when protected pipes are not used.

H05VV

NOTE

■

Select the power supply cable in accordance with

relevant local and national regulations.

■

Wire size must comply with the applicable local

and national code.

■

Specifications for local wiring power cord and

branch wiring are in compliance with IEC60245.

After finishing the electric work, confirm that each electric

part and terminal inside the electric parts box is connected

securely.

(1) European/International Technical Standard setting the limits for harmonic

currents produced by equipment connected to public low-voltage systems

with input current >16 A and

≤

75 A per phase.