Installation manual

17

ERQ100~140A7V1B

Inverter condensing unit

4PW51321-1

3.3 Possible settings for function D and E

For function D (

) only: the noise of level

3<

level 2< level 1 (

).

For function E (

) only: the power consumption of

level 1< level 2 < level 3 (

).

4

Push the

button and the setting is defined.

5

When the

button is pushed again, the operation

starts according to the setting.

Refer to the service manual for more details and for other settings.

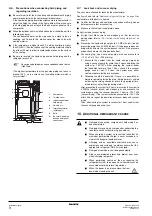

Confirmation of the set mode

The following items can be confirmed by setting mode 1 (H1P

led is off)

Check the led indication in the field marked

.

1

Indication of the present operation state

2

Indication of COOL/HEAT selection setting

3

Indication of low noise operation state

4

Indication of power consumption limitation setting

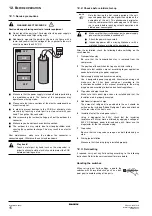

12.4. Test operation

■

Check the stop valves

Make sure to open the gas and liquid line stop valves.

■

After installation, perform the test operation.

Unless the test operation is performed, the error code "

U3

" is

shown on the remote controller and the unit cannot be operated.

Performing the test operation

1

To protect the compressor, make sure to turn on the power

supply 6 hours before starting operation.

2

Set to setting mode 1 (H1P led is off) (refer to

3

Press the

button for 5 seconds when the unit is at a

standstill. The test operation starts when the H2P led blinks and

the remote controller indicates

(test operation) and

(external control).

It may take 10 minutes to bring the state of refrigerant uniform

before the compressor starts, but that is not a malfunction.

The test operation is automatically carried out in cooling mode

during 15~30 minutes.

Depending on the situation, the refrigerant running sound or the

sound of a magnetic solenoid valve may rise during this

operation.

The following items are automatically checked:

-

Check for incorrect wiring

-

Check if stop valves are open

-

Check of refrigerant charge

-

Automatic judgement of piping length

4

After the test operation (maximum 30 minutes), the unit

automatically stops. Check the operation results by the outdoor

unit led indication.

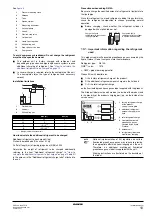

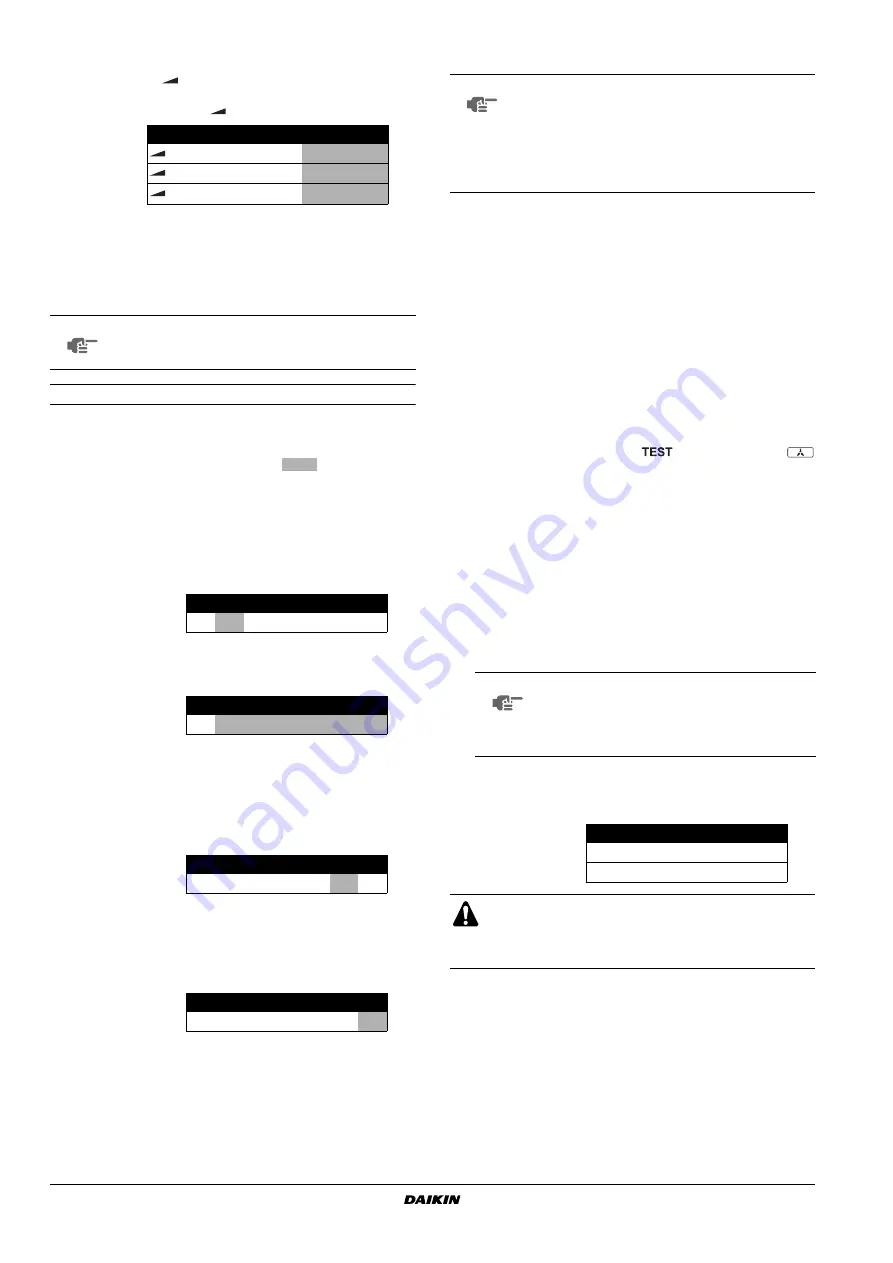

H1P

H2P

H3P

H4P

H5P

H6P

H7P

w x

x

x

x

x c

(*)

(*)

This setting = factory setting.

w x

x

x

x c x

w x

x

x c x

x

NOTE

When finished, please mark the settings of function C,

D and E in the "Records" part of the label on the

backside of the front plate.

x

normal

w

abnormal

c

under preparation or under test operation

H1P

H2P

H3P

H4P

H5P

H6P

H7P

x

x w x

x

x

x

1

When set to COOL/HEAT change-over by each individual outdoor

unit circuit (= factory setting).

H1P

H2P

H3P

H4P

H5P

H6P

H7P

1

(*)

(*)

This setting = factory setting.

x

x w x

x

x

x

x

standard operation (= factory setting)

w

operation

H1P

H2P

H3P

H4P

H5P

H6P

H7P

x

x w x

x

x

x

x

standard operation (= factory setting)

w

operation

H1P

H2P

H3P

H4P

H5P

H6P

H7P

x

x w x

x

x

x

L.N.O.P

1

DEMAND

3

1

2

3

BS3 RETURN

BS3 RETURN

L.N.O.P

L.N.O.P

DEMAND

DEMAND

NOTE

■

After turning on the power supply, the unit can not

be started until the H2P initialisation led goes off

(maximum 12 minutes).

■

Depending on the application, it is possible that

the remote controller is required for performing

settings during first installation and servicing only

(service tool).

NOTE

When you want to terminate the test operation,

press the

button. The unit will keep

running for 30 seconds and then stops. During

test operation it is impossible to stop the unit with

the remote controller.

H1P

H2P

H3P

H4P

H5P

H6P

H7P

normal

x

x w x

x

x

x

abnormal

x w x

x

x

x

x

■

The led indication changes during this operation, but

that is not abnormal.

■

Please attach the front plate of the outdoor unit in

order to prevent electric shocks.

BS4 TEST

BS3 RETURN