ERQ100~14 ERQ125~250A7W1B

Inverter condensing unit

4PW51322-1B – 2018.04

Operation manual

3

4.

R

EMOTE

CONTROLLER

Refer to the operation manual of the remote controller.

5.

C

HANGEOVER

SWITCH

: N

AME

AND

FUNCTION

OF

EACH

SWITCH

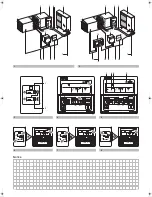

(See figure 3)

1

FAN ONLY/AIR CONDITIONING SELECTOR SWITCH

Set the switch to

for fan only operation or to

for heating or

cooling operation.

2

COOL/HEAT CHANGEOVER SWITCH

Set the switch to

for cooling or to

for heating operation.

6.

O

PERATION

RANGE

Operation range

Use the system in the following temperature and humidity ranges for

safe and effective operation.

7.

O

PERATION

PROCEDURE

■

Operation procedure varies according to the combination of

outdoor unit and remote controller. Read

"3. What to do before

operation" on page 2

.

■

To protect the unit, turn on the main power switch 6 hours before

operation.

■

If the main power supply is turned off during operation, operation

will restart automatically after the power turns back on again.

■

Refer to the manual supplied with the control box for operation

and functionality.

■

Refer to the manual supplied with the remote controller for

operation and functionality.

7.1.

Cooling, heating, and fan only operation

(See

figure 4

and

figure 6

)

The fan may keep on running for a while after the heating operation

stops.

For systems with Daikin remote controller and without cool/

heat changeover remote control switch

(See figure 4)

1

Press the operation mode selector button several times and

select the operation mode of your choice.

2

Press the on/off button.

The operation lamp lights up and the system starts operation.

For systems with cool/heat changeover remote control switch

1

Select operation mode with the cool/heat changeover remote

control switch as follows:

2

Press the on/off button or close T1/T2.

The operation lamp lights up and the system starts operation.

For systems without Daikin remote controller, without cool/

heat changeover remote control switch and with a field

supplied controller

1

Select operation mode with the field supplied controller.

2

Close T1/T2.

The operation lamp lights up and the system starts operation.

Adjustment

For programming temperature refer to the operation manual of the

remote controller.

Stopping the system

3

Press the on/off button once again or open T1/T2.

The operation lamp goes off and the system stops operation.

Explanation of heating operation

It may take longer to reach the set temperature for general heating

operation than for cooling operation.

The following operation is performed in order to prevent the heating

capacity from dropping or cold air from blowing.

Defrost operation

■

In heating operation, freezing of the outdoor unit coil increases.

Heating capability decreases and the system goes into defrost

operation.

■

The air handling unit fan stops and the remote controller

displays .

■

In case no remote controller is installed, a defrost signal is

outputted from the control box.

■

After maximum 10 minutes of defrost operation, the system

returns to heating operation again.

Hot start

In order to prevent cold air from blowing out of an air handling unit at

the start of heating operation, the air handling unit fan can be

stopped, depending on the control of the air handling unit.

In case a remote controller is installed, the remote controller displays

. It may take some time before the fan starts. This is not a

malfunction.

ERQ125~250_W1

ERQ100~140_V1

Outdoor

temperature

–5~43°C DB

–20~21°C DB

–5~46°C DB –20~24°C DB

(*)

(*) Range for operation: –20~–15°C WB. Range for continuous operation:

–15~15.5°C WB.

–20~15.5°C WB

–20~15.5°C WB

Indoor

temperature

21~32°C DB

15~27°C DB

21~32°C DB

15~27°C DB

14~25°C WB

14~25°C WB

Indoor

humidity

≤

80%

(†)

(†) to avoid condensation and water dripping out the unit.

If the temperature or the humidity is beyond these conditions, safety devices may

work and the air conditioner may not operate.

≤

80%

(†)

Cooling operation

Heating operation

Fan only operation

Cooling operation (

figure 6

)

Heating operation (

figure 7

)

Fan only operation (

figure 8

)

NOTE

Do not turn off power immediately after the unit stops,

but wait for at least 5 minutes.

4PWEN51322-1B_2018_04.book Page 3 Thursday, June 7, 2018 9:42 PM

Summary of Contents for ERQ100A7V1B

Page 10: ......

Page 11: ......

Page 12: ...4PW51322 1B 2018 04 Copyright Daikin 4PW51322 1 B 0000000G ...