Operation manual

6

ERQ100~14 ERQ125~250A7W1B

Inverter condensing unit

4PW51322-1B – 2018.04

3

The system operates but cooling or heating is insufficient

■

Check if air inlet or outlet of outdoor or air handling unit is not

blocked by obstacles.

■

Remove any obstacle and make it well-ventilated.

■

Check if the air filter is not clogged. (Refer to "Maintenance" in

the air handling unit manual.)

■

Check the temperature setting.

■

Check the fan speed setting on your remote controller.

■

Check for open doors or windows. Shut doors and windows to

prevent wind from coming in.

■

Check if there are too many occupants in the room during

cooling operation

■

Check if the heat source of the room is excessive.

■

Check if direct sunlight enters the room. Use curtains or blinds.

■

Check if the air flow angle is proper.

If after checking all above items, it is impossible to fix the problem

yourself, contact your dealer and state the symptoms, the complete

model name of the air conditioner (with manufacturing number if

possible) and the installation date (possibly listed on the warranty

card).

12. A

FTER

-

SALES

SERVICE

AND

WARRANTY

Warranty period

■

This product includes a warranty card that was filled out by the

dealer at the time of installation. The completed card was

checked by the customer and stored carefully.

■

If repairs to the air conditioner are necessary within the warranty

period, contact your dealer and keep the warranty card at hand.

12.1.

After-sales service

■

Recommendations for maintenance and inspection

Since dust collects when using the unit for several years,

performance of the unit will deteriorate to some extent.

As taking apart and cleaning interiors of units requires technical

expertise and in order to ensure the best possible maintenance

of your units, we recommend to enter into a maintenance and

inspection contract on top of normal maintenance activities.

Our network of dealers has access to a permanent stock of

essential components in order to keep your air conditioner in

operation as long as possible.

Contact your dealer for more information.

■

When asking your dealer for an intervention, always state:

• the complete model name of the air conditioner

• the manufacturing number (stated on the nameplate of the

unit)

• the installation date

• the symptoms or malfunction, and details of the defect.

■

Recommended inspection and maintenance cycles

Be aware that the mentioned maintenance and replacement cycles

do not relate to the warranty period of the components.

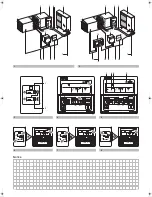

Table 1:

"Inspection Cycle" and "Maintenance Cycle" list

Table 1 assumes the following conditions of use:

1.

Normal use without frequent starting and stopping of the unit.

Depending on the model, we recommend not starting and

stopping the machine more than 6 times/hour.

2.

Operation of the unit is assumed to be 10 hours/day and 2,500

hours/year.

12.2.

Shortening of "maintenance cycle" and

"replacement cycle" needs to be considered in

following situations

■

The unit is used in locations where:

1.

heat and humidity fluctuate out of the ordinary

2.

power fluctuation is high (voltage, frequency, wave distortion,

etc.)

(The unit cannot be used if power fluctuation is outside the

allowable range.)

3.

bumps and vibrations are frequent

4.

dust, salt, harmful gas or oil mist such as sulfurous acid and

hydrogen sulfide may be present in the air

5.

the machine is started and stopped frequently or operation time

is long (sites with 24 hour air-conditioning).

WARNING

■

Do not modify, disassemble, remove, reinstall or

repair the unit yourself as incorrect dismantling or

installation may cause an electric shock or fire.

Contact your dealer.

■

In case of accidental refrigerant leaks, make sure

there are no naked flames. The refrigerant itself is

entirely safe, non-toxic and non-combustible, but it will

generate toxic gas when it accidentally leaks into a

room where combustible air from fan heaters, gas

cookers, etc. ... is present.

Always have qualified service personnel confirm that

the point of leakage has been repaired or corrected

before resuming operation.

Component

Inspection cycle

Maintenance cycle

(replacements and/

or repairs)

Electric motor

1 year

20,000 hours

PCB

25,000 hours

Heat exchanger

5 years

Sensor (thermistor, etc.)

5 years

Remote controller and switches

25,000 hours

Drain pan

8 years

Expansion valve

20,000 hours

Electromagnetic valve

20,000 hours

NOTE

1.

Table 1 indicates main components.

Refer to your maintenance and inspection contract

for more details.

2.

Table 1 indicates recommended intervals of

maintenance cycles. However, in order to keep

the unit operational as long as possible,

maintenance work may be required sooner.

Recommended intervals can be used for

appropriate maintenance design in terms of

budgetting maintenance and inspection fees.

Depending on the content of the maintenance and

inspection contract, inspection and maintenance

cycles may in reality be shorter than listed.

4PWEN51322-1B_2018_04.book Page 6 Thursday, June 7, 2018 9:42 PM

Summary of Contents for ERQ100A7V1B

Page 10: ......

Page 11: ......

Page 12: ...4PW51322 1B 2018 04 Copyright Daikin 4PW51322 1 B 0000000G ...