ERQ100~14 ERQ125~250A7W1B

Inverter condensing unit

4PW51322-1B – 2018.04

Operation manual

7

■

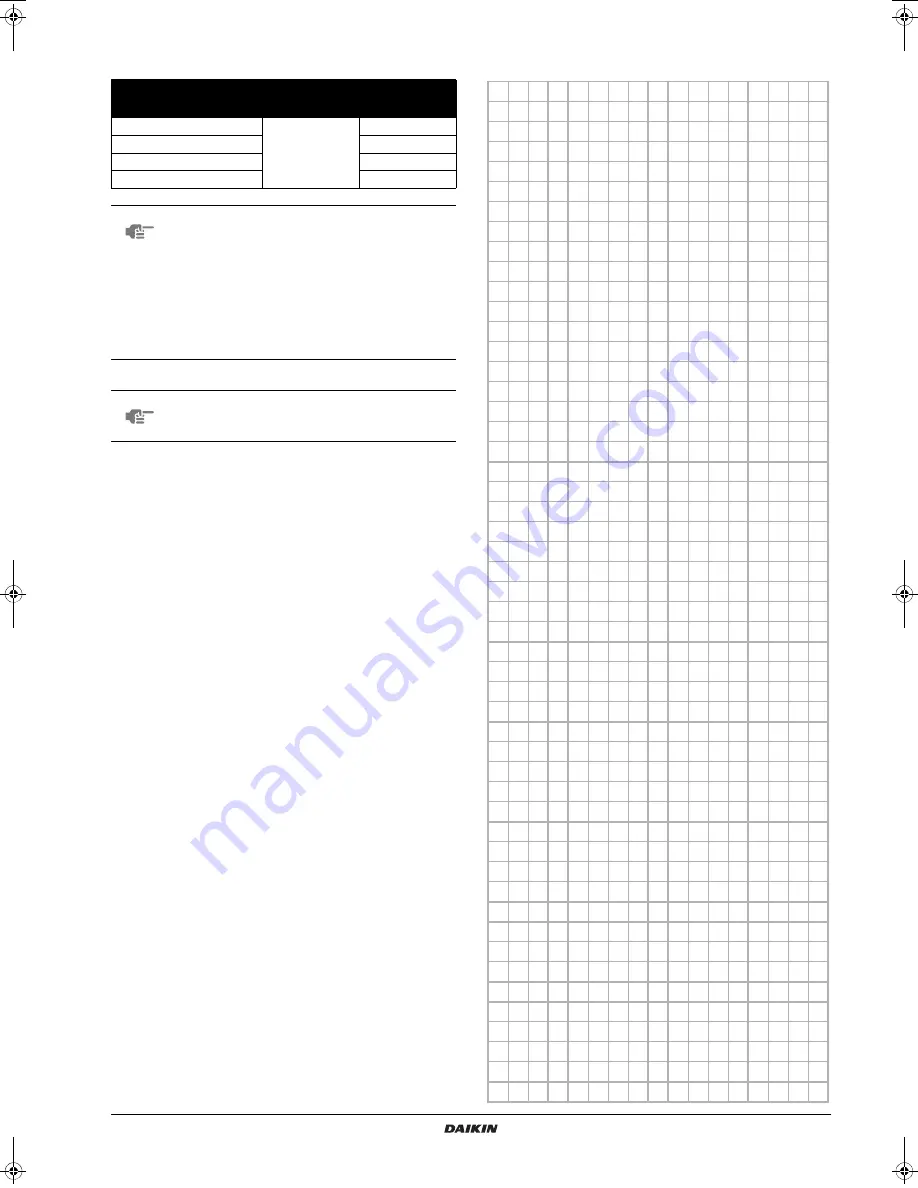

Recommended replacement cycle of wear parts

Table 2:

"Replacement Cycle" list

Contact your dealer for details.

■

Moving and discarding the unit

■

Contact your dealer for removing and reinstalling the total

unit. Moving units requires technical expertise.

■

This unit uses hydrofluorocarbon.

Contact your dealer when discarding this unit. It is required

by law to collect, transport and discard the refrigerant in

accordance with the "hydrofluorocarbon collection and

destruction" regulations.

N

OTES

Component

Inspection cycle

Maintenance cycle

(replacements and/

or repairs)

Air filter

1 year

5 years

High efficiency filter (Optional)

1 year

Fuse

10 years

Crankcase heater

8 years

NOTE

1.

Table 2 indicates main components.

Refer to your maintenance and inspection contract

for more details.

2.

Table 2 indicates recommended intervals of

replacement cycles. However, in order to keep the

unit operational as long as possible, maintenance

work may be required sooner.

Recommended intervals can be used for

appropriate maintenance design in terms of

budgetting maintenance and inspection fees.

NOTE

Damage due to taking apart or cleaning interiors of

units by anyone other than our authorised dealers may

not be included in the warranty.

4PWEN51322-1B_2018_04.book Page 7 Thursday, June 7, 2018 9:42 PM

Summary of Contents for ERQ100A7V1B

Page 10: ......

Page 11: ......

Page 12: ...4PW51322 1B 2018 04 Copyright Daikin 4PW51322 1 B 0000000G ...