ERQ100~140A7V1B

Inverter condensing unit

4PW51321-1

Installation manual

8

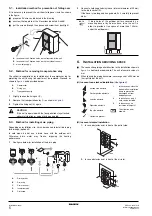

For ERQ140 only

The size of the gas side stop valve is Ø15.9 while the inter-unit piping

is Ø19.1. Use the standard supplied accessory piping to make the

connection. See

9.1.

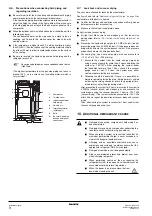

Preventing foreign objects from entering

Plug the pipe through-holes with putty or insulating material (field

supply) to stop up all gaps, as shown in the figure.

Insects or small animals entering the outdoor unit may cause a short

circuit in the electrical box.

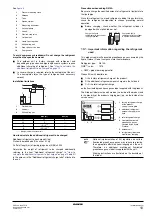

9.2.

Cautions for handling stop valve

■

The stop valves for air handling unit-outdoor connecting piping

are closed at shipment from the factory.

The names of parts of the stop valve are shown in the figure.

■

Since the side boards may be deformed if only a torque wrench

is used when loosening or tightening flare nuts, always lock the

stop valve with a wrench and then use a torque wrench.

Do not place wrenches on the valve cover.

Do not apply force on the valve cover, this may result in a

refrigerant leak.

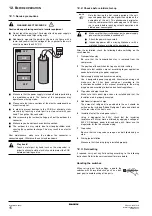

■

For cooling operation under low ambient temperature or any

other operation under low pressure, apply silicon pad or similar

to prevent freezing of the gas stop valve flare nut (see figure).

Freezing of the flare nut may cause refrigerant leak.

9.3.

How to use the stop valve

Use hexagonal wrenches 4 mm and 6 mm.

■

Opening the valve

1.

Place the hex wrench on the valve bar and turn counter-

clockwise.

2.

Stop when the valve bar no longer turns. It is now open.

■

Closing the valve

1.

Place the hex wrench on the valve bar and turn clockwise.

2.

Stop when the valve bar no longer turns. It is now closed.

9.4.

Cautions for handling the valve cover

■

The valve cover is sealed where

indicated by the arrow.

Take care not to damage it.

■

After operating the valve, be sure to tighten the valve cover

properly.

■

Check for refrigerant leakage after tightening the cap.

9.5.

Cautions for handling service port

After the work, tighten the valve cover in place.

Tightening torque: 11.5~13.9 N•m

A

Front connection

B

Rear connection

C

Side connection

D

Bottom connection

1

Gas line copper gasket supplied with the unit (make sure

to always use the copper gasket).

2

Gas line piping supplied with the unit

3

Gas piping (field supply)

4

Cut to the appropriate length.

5

Gas line piping supplied with the unit

1

Putty or insulating material (field

supply)

Make sure to keep the valve open during operation.

1

Service port

2

Stop valve

3

Field piping connection

4

Valve cover

1

Spanner

2

Torque wrench

1

3

4

1

2

1

2

Silicon sealing pad

(Make sure there is no gap)

Closing direction

Liquid side

Gas side

Tightening torque

Liquid pipe

13.5~16.5 N•m

Gas pipe

22.5~27.5 N•m