Installation manual

11

ERQ100~140A7V1B

Inverter condensing unit

4PW51321-1

10.2. 2 procedures for adding refrigerant

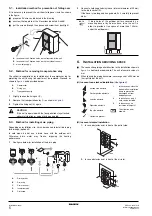

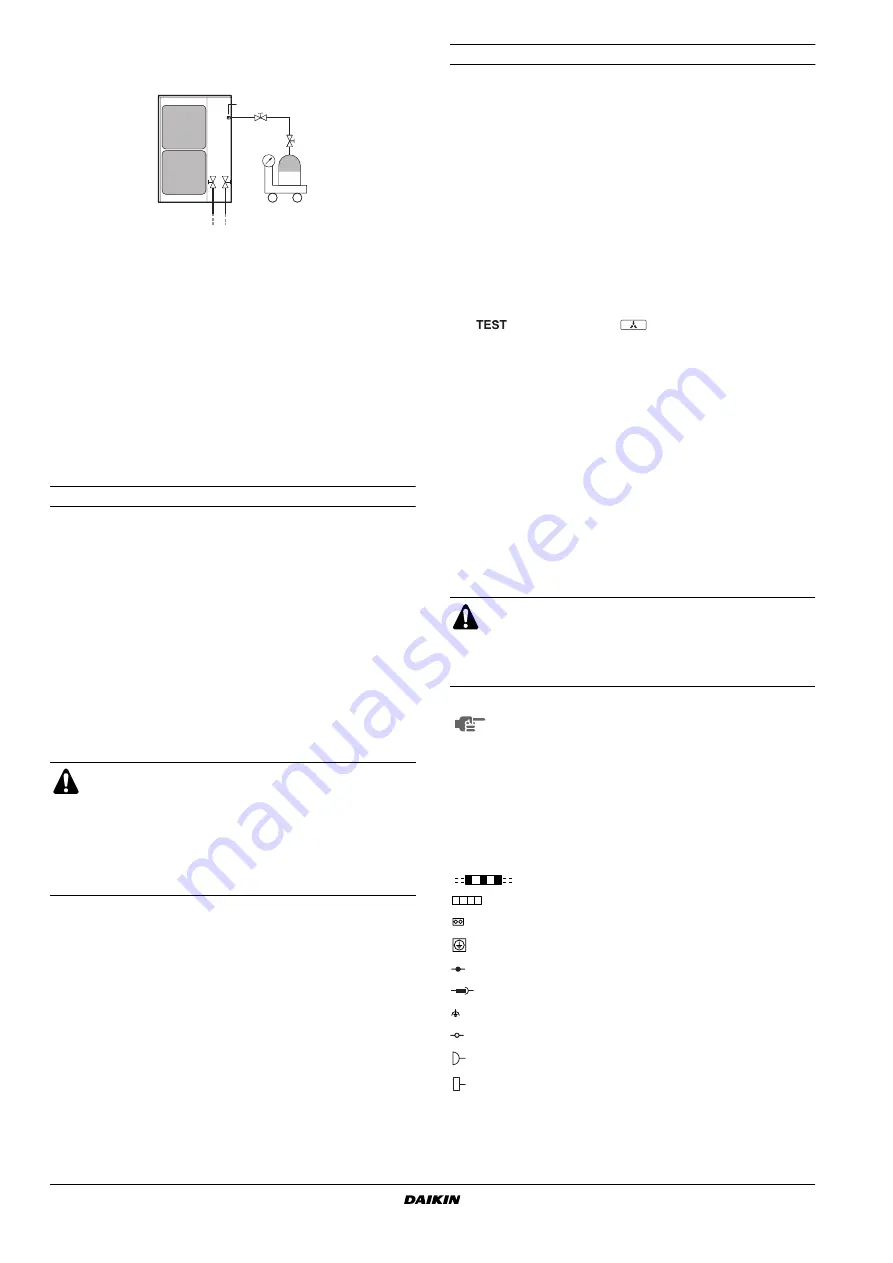

How to connect the tank?

When the refrigerant tank is connected and the specified operation is

performed, the appropriate amount of refrigerant will be charged into

the system. After charging, the system will stop automatically. The

refrigerant must be charged according to the procedure described

below.

Procedure 1: Charging while the outdoor unit is at a standstill

See

1

Determine the weight of refrigerant to be charged additionally

referring to the item "Additional refrigerant charge" in

calculate the additional refrigerant to be charged" on page 10

and fill in the amount in the "Additional refrigerant charge label"

attached to the unit.

2

After the vacuum drying is finished, open valve A and charge the

additional refrigerant in its liquid state through the service port

on the liquid stop valve taking into account following instructions:

-

Turn on the power of the outdoor unit, control box and air

handling units.

-

Check that gas and liquid stop valves are closed.

-

Stop the compressor and charge the specified weight of

refrigerant.

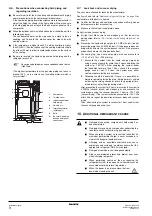

Procedure 2: Charging while the outdoor unit is operating

"How to connect the tank?" on page 11

1

Completely open the gas side stop valve and liquid side stop

valve. Valve A must be left fully closed.

2

Close the front panel and turn on the power to the control box,

air handling unit and the outdoor unit.

3

Open valve A immediately after starting of the compressor.

4

Charge the additional refrigerant in its liquid state through the

service port of the liquid line stop valve.

5

While the unit is at a standstill and under setting mode 2 (refer to

Checks before initial start-up

set the required function A (additional refrigerant charging

operation) to

(ON). Then operation starts. The blinking H2P

led indicates test operation and the remote controller indicates

(test operation) and

(external control).

6

When the specified amount of refrigerant is charged, push the

button. Then operation stops.

■

The operation automatically stops within 30 minutes.

■

If the refrigerant charge cannot be finished within 30 minutes,

repeat step

■

If the operation stops immediately after restart, there is a

possibility that the system is overcharged.

The refrigerant cannot be charged more than this amount.

7

After the refrigerant charge hose is removed, make sure to close

valve A.

11. E

LECTRICAL

WIRING

WORK

11.1. Internal wiring – Parts table

L............................. Live

N ............................ Neutral

........... Field wiring

.................... Terminal strip

......................... Connector

......................... Protective earth (screw)

.......................... Connection

....................... Relay connector

........................... Functional earthing

.......................... Terminal

......................... Movable connector

.......................... Fixed connector

BLU........................ Blue

BRN ....................... Brown

GRN....................... Green

RED ....................... Red

1

Liquid line stop valve

2

Gas line stop valve

3

To air handling unit

4

Service port for adding refrigerant

5

Valve A

6

R410A tank

7

Measuring instrument

8

Pipe fixing plate

■

To avoid compressor breakdown. Do not charge the

refrigerant more than the specified amount.

■

If the total refrigerant cannot be charged while the

outdoor unit is at a standstill, it is possible to charge

the refrigerant by operating the outdoor unit using the

refrigerant charge function (refer to

) and follow

the outdoor unit is operating" on page 11

3

6

7

1 2

4

5

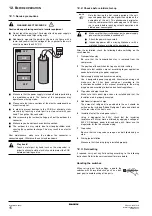

■

All wiring must be performed by an authorized

electrician.

■

All field supplied components and all electric

construction should comply with the applicable local

and national codes.

To persons in charge of electrical wiring work:

Do not operate the unit until the refrigerant piping is

complete. (Running it before the piping is ready will break

the compressor.)

ON

BS3 RETURN