Installation manual

15

ERQ100~140A7V1B

Inverter condensing unit

4PW51321-1

12. B

EFORE

OPERATION

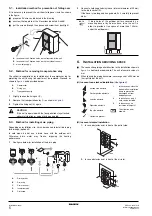

12.1. Service precautions

Caution when performing service to inverter equipment

■

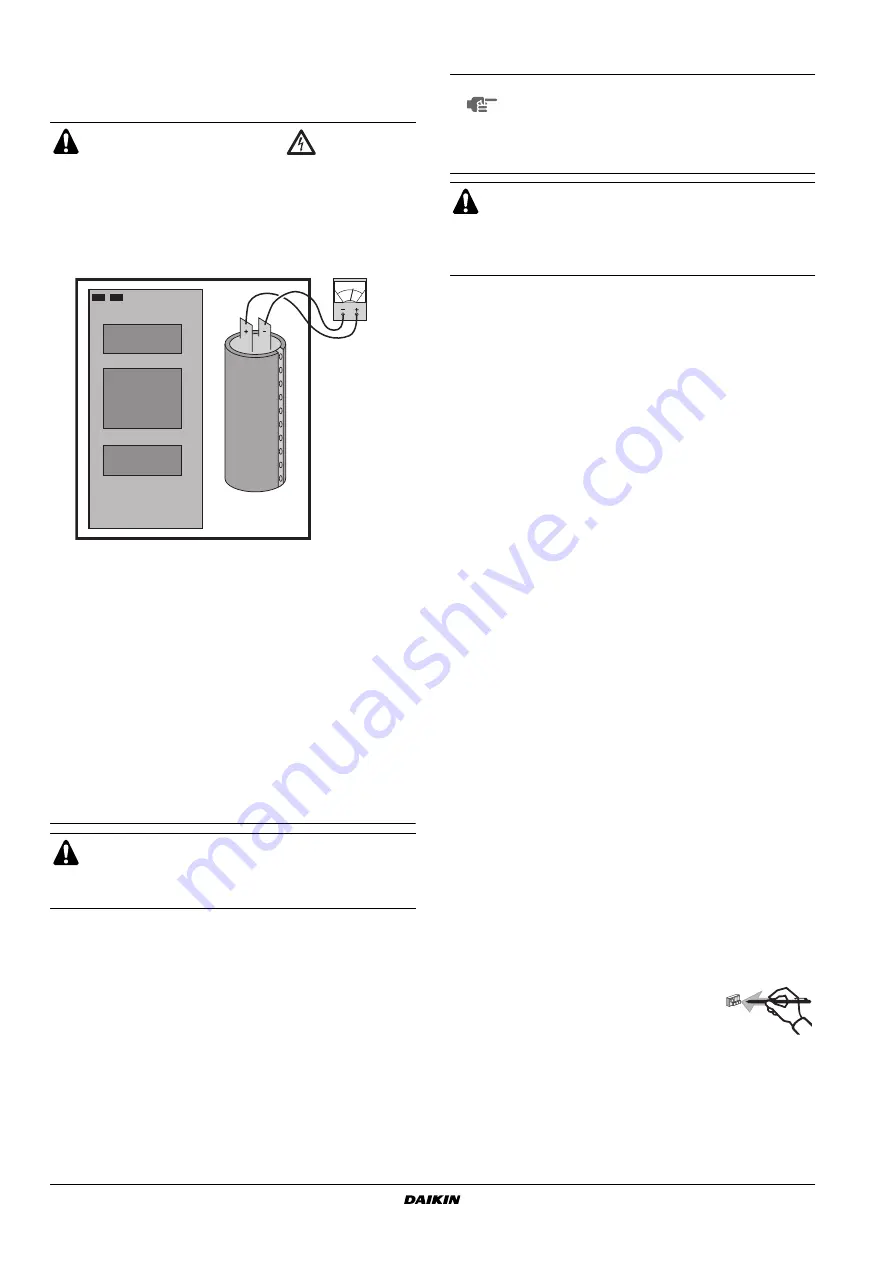

Do not touch live parts for 10 minutes after the power supply is

turned off because of high voltage risk.

■

Additionally, measure the points as shown in the figure with a

tester and confirm that the voltage of the capacitor in the main

circuit is no more than 50 V DC.

■

Make sure that the power supply is turned off before performing

the maintenance work. The heater of the compressor may

operate even in stop mode.

■

Please note that some sections of the electric component box

are extremely hot.

■

In order to prevent damage to the PCB, first eliminate static

electricity by touching a metal part (e.g. stop valve) with your

hand. Then pull out the connector.

■

After measuring the residual voltage, pull out the outdoor fan

connector.

■

Make sure you do not touch a conductive section.

■

The outdoor fan may rotate due to strong backblow wind,

causing the capacitor to charge. This may result in an electric

shock.

After maintenance, make sure the outdoor fan connector is

connected again. Otherwise, the unit may break down.

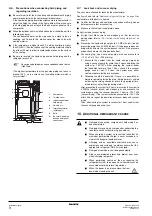

12.2. Checks before initial start-up

After the installation, check the following before switching on the

circuit breaker:

1

Transportation stay

Be sure that the transportation stay is removed from the

compressor.

2

The position of the switches that require an initial setting

Make sure that switches are set according to your application

needs before turning the power supply on.

3

Power supply wiring and transmission wiring

Use a designated power supply and transmission wiring and

make sure that it has been carried out according to the

instructions described in this manual, according to the wiring

diagrams and according to local and national regulations.

4

Pipe sizes and pipe insulation

Make sure that correct pipe sizes are installed and that the

insulation work is properly executed.

5

Additional refrigerant charge

The amount of refrigerant to be added to the unit should be

written on the included "Added Refrigerant" plate and attached

to the rear side of the front cover.

6

Insulation test of the main power circuit

Using a megatester for 500

V, check that the insulation

resistance of 2 M

Ω

or more is attained by applying a voltage of

500 V DC between power terminals and earth. Never use the

megatester for the transmission wiring.

7

Stop valves

Be sure that the stop valves are open on both liquid and gas

side.

8

Drain pipe installation

Make sure that the drain piping is installed properly.

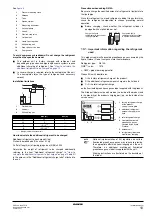

12.3. Field setting

If required, carry out any field setting according to the following

instructions. Refer to the service manual for more details.

Handling the switches

When carrying out field settings, operate the

switches with an insulated stick (such as a ball-

point pen) to avoid touching of live parts.

WARNING: ELECTRIC SHOCK

Play it safe!

Touch a metal part by hand (such as the stop valve) in

order to eliminate static electricity and to protect the PCB

before performing service.

A2P

A1P

A1P

X2M

A4P

X106A X107A

NOTE

Note that during the first running period of the unit,

required power input may be higher than stated on the

nameplate of the unit. This phenomenon originates

from the compressor that needs elapse of a 50 hours

run in period before reaching smooth operation and

stable power consumption.

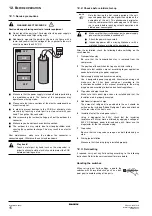

■

Make sure that the circuit breaker on the power supply

panel of the installation is switched off.

■

Attach the power wire securely.

■

Introducing power with a missing N-phase or with a

mistaken N-phase will break the equipment.