ERQ100~140A7V1B

Inverter condensing unit

4PW51321-1

Installation manual

6

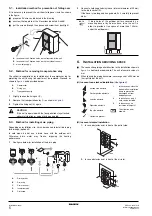

(C) In case of multiple-row installation (for roof top use, etc.)

1.

In case of installing one unit per row.

2.

In case of installing multiple units (2 units or more) in lateral

connection per row.

Relation of dimensions between H, A and L is shown in the table

below.

7.

R

EFRIGERANT

PIPE

SIZE

AND

ALLOWABLE

PIPE

LENGTH

7.1.

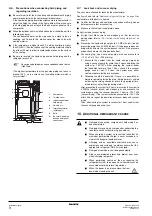

Selection of piping material

■

Foreign materials inside pipes (including oils for fabrication)

must be

≤

30 mg/10 m.

■

Construction material: phosphoric acid deoxidized seamless

copper for refrigerant.

■

Temper grade: use piping with temper grade in function of the

pipe diameter as listed in table below.

■

The pipe thickness of the refrigerant piping should comply with

relevant local and national regulations. The minimal pipe

thickness for R410A piping must be in accordance with the table

below.

O = Annealed

1/2H = Half hard

■

In case the required pipe sizes (inch sizes) are not available, it is

also allowed to use other diameters (mm sizes), taken the

following into account:

■

select the pipe size nearest to the required size.

■

use the suitable adapters for the change-over from inch to

mm pipes (field supply).

8.

P

RECAUTIONS

ON

REFRIGERANT

PIPING

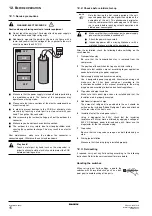

■

Do not allow anything other than the designated refrigerant to

get mixed into the freezing cycle, such as air, etc. If any

refrigerant gas leaks while working on the unit, ventilate the

room thoroughly right away.

■

Use R410A only when adding refrigerant

Installation tools:

Make sure to use installation tools (gauge manifold charge

hose, etc.) that are exclusively used for R410A installations

to withstand the pressure and to prevent foreign materials

(e.g. mineral oils and moisture) from mixing into the system.

Vacuum pump:

Use a 2-stage vacuum pump with a non-return valve

Make sure the pump oil does not flow oppositely into the

system while the pump is not working.

Use a vacuum pump which can evacuate to –100.7 kPa

(5 Torr, –755 mm Hg).

■

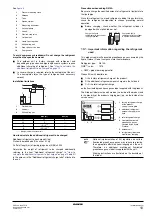

In order to prevent dirt, liquid or dust from entering the piping,

cure the piping with a pinch or taping.

Great caution is needed when passing copper tubes through

walls.

■

For handling of stop valves, refer to

■

Only use the flare nuts included with the unit. Using different

flare nuts may cause the refrigerant to leak.

■

Always use the supplied copper gasket when connecting the

gas pipe supplied with the unit. See

NOTE

■

Do not stack more than one unit.

■

About 100 mm is required as the dimension

for laying the upper outdoor unit’s drain pipe.

■

Get the portion A sealed so that air from the

outlet does not bypass.

L

A (mm)

L

≤

H

0<L

≤

1/2H

250

1/2H<L

≤

H

300

H<L

Installation impossible

All field piping must be installed by a licensed refrigeration

technician and must comply with relevant local and

national regulations.

To persons in charge of piping work:

■

Be sure to open the stop valve after piping installing

and vacuuming is complete. (Running the system with

the valve closed may break the compressor.)

■

It is forbidden to discharge refrigerant into the

atmosphere. Collect the refrigerant in accordance

with the freon collection and destruction law.

■

Do not use flux when brazing the refrigerant piping.

For brazing, use phosphor copper brazing filler metal

(BCuP) which does not require a flux.

(If a chlorine flux is used, the piping will corrode, and if

the flux contains fluoride, it will cause the coolant oil to

deteriorate, adversely affecting the coolant piping

system.

■

Do not use materials not compatible with copper.

Example: Aluminium heat exchanger may be cause of

corrosion.

≥

1000

≥

200

≥

2000

≥

100

≥

1500

≥

600

≥

3000

A

H

L

Pipe Ø

Temper grade of piping

material

Minimal thickness t

(mm)

6.4 / 12.7

O

0.80

15.9

O

1

19.1

1/2H

1

Installation period

Protection method

More than a month

Pinch the pipe

Less than a month

Pinch or tape the

pipe

Regardless of the

period