Installation manual

12

ERX125~250A7W1B

Inverter condensing unit

4PW30064-1D

1.

Remove the cap and turn the valve counterclockwise with the

hexagon wrench.

2.

Turn it until the shaft stops.

3.

Make sure to tighten the cap securely. Refer to the table below

Closing stop valve

1.

Remove the cap and turn the valve clockwise with the hexagon

wrench.

2.

Securely tighten the valve until the shaft contacts the main body

seal.

3.

Make sure to tighten the cap securely.

For the tightening torque, refer to the table above.

11.4. Additional refrigerant charge

Follow the procedures below.

1

Adding additional refrigerant

■

Charge with the outdoor unit at standstill

1.

Calculate how much refrigerant to be added using the formula

explained in the chapter

"4.2 How to calculate the additional

refrigerant to be charged" on page 6

2.

Open valve C (valves A and B and the stop valves must be left

closed) and charge the required amount of refrigerant through

the liquid side stop valve service port.

■

When the required amount of refrigerant is fully charged,

close valve C. Record, with a permanent marker, the amount

of refrigerant that was added on the wiring diagram attached

on the inside of the switch box.

Perform the test procedure as described in

refrigerant was added at standstill" on page 16

■

When the additional charging is not complete, perform the

procedure explained in the chapter

■

Charge with operating outdoor unit

Charge the refrigerant through valve A.

1.

Start of charging refrigerant manually

-

Open the liquid and gas side stop valves and the service port

stop valve. (Valves A, B and C must be closed.)

-

Close all front panels except the electric box front panel and

turn the power ON.

-

Make sure the control box and evaporator unit are operating.

-

If the H2P LED is not flashing (in 12 minutes time after

turning on the power), make sure it is displayed as shown

below.

If the H2P LED is flashing, check the malfunction code on the

remote controller

"3 Remote controller malfunction code

Do not apply excessive force to the stop valve. Doing

so may break the valve body, as the valve is not a

backseat type. Always use the special tool.

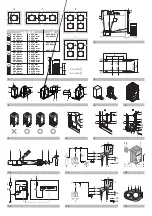

Stop valve size

Tightening torque N•m (Turn clockwise to close)

Shaft

Cap (valve lid)

Service port

Valve body

Hexagonal

wrench

Ø9.5

5.4~6.6

4 mm

13.5~16.5

11.5~13.9

Ø15.9

13.5~16.5

6 mm

23.0~27.0

Ø19.1

27.0~33.0

8 mm

22.5~27.5

Ø25.4

■

When charging a system, charging over the

permissible quantity can cause liquid hammer.

■

Always use protective gloves and protect your eyes

when charging refrigerant.

■

When the refrigerant charging procedure is done or

when pausing, close the valve of the refrigerant tank

immediately. If the tank is left with the valve open, the

amount of refrigerant which is properly charged may

get off point. More refrigerant may be charged by any

remaining pressure after the unit has stopped.

Electric shock warning

■

Close the electric box lid before turning on the main

power.

■

Perform the settings on the circuit board (A1P) of the

outdoor unit and check the LED display after the

power is on via the service lid which is in the lid of the

electric box.

Operate switches with an insulated

stick (such as a ball-point pen) to

avoid touching the life parts.

Make sure to re-attach the

inspection cover into the switch box cover after the job

is finished.

■

If the power of some units is turned off, the charging

procedure can not be finished properly.

■

Make sure to turn ON the power 6 hours before

starting the operation. This is necessary to warm the

crankcase by the electric heater.

■

If operation is performed within 12 minutes after the

indoor and outdoor units are turned on, the H2P-led

will be lit and the compressor will not operate.

NOTE

■

See

"11.3. Stop valve operation procedure" on

for details on how to handle stop valves.

■

The refrigerant charging port is connected to the

piping inside the unit.

The unit's internal piping is already factory

charged with refrigerant, so be careful when

connecting the charge hose.

■

After adding the refrigerant, do not forget to close

the lid of the refrigerant charging port.

The tightening torque for the lid is 11.5 to

13.9 N•m.

■

In order to ensure uniform refrigerant distribution,

it may take the compressor ±10 minutes to start

up after the unit has started operation. This is not

a malfunction.

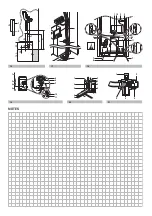

1

Measuring instrument

2

Tank (siphon system)

3

Charge hose

4

Liquid line stop valve

5

Gas line stop valve

6

Stop valve service port

7

Valve B

8

Valve C

9

Valve A

10

Outdoor unit

11

Refrigerant charge port

12

To air handling unit

13

Inter-unit piping

14

Refrigerant flow