ERX125~250A7W1B

Inverter condensing unit

4PW30064-1D

Installation manual

17

Test operation procedure

1

Close all front panels except the front panel of the electric box.

2

Turn ON the power to all outdoor units and the connected units.

Be sure to turn on the power 6 hours before operation in order to

have power running to the crank case heater and to protect the

compressor.

3

Make the field setting as described in the paragraph

.

4

Press the

button once, and set to the SETTING

MODE (H1P LED = OFF).

5

Press and hold the

button down for 5 seconds or

more. The unit will start the test operation.

■

The test operation is automatically carried out in cooling

mode, the H2P LED will light up and the messages "Test

operation" and "Under centralized control" will display on the

remote controller.

■

It may take 10 minutes to bring the state of the refrigerant

uniform before the compressor starts.

■

During the test operation, the refrigerant running sound or

the magnetic sound of a solenoid valve may become loud

and the LED display may change, but these are not mal-

functions.

■

During the test operation, it is not possible to stop the unit

operation from a remote controller. To abort the operation,

press the

button. The unit will stop after

±30 seconds.

6

Close the front panel in order to let it not be the cause of

misjudgement.

7

Check the test operation results by the LED display on the

outdoor unit.

8

When the test operation is fully completed, normal operation will

be possible after 5 minutes.

Otherwise, refer to

"Correcting after abnormal completion of the

to take actions for correcting the

abnormality.

Correcting after abnormal completion of the test operation

The test operation is only completed if there is no malfunction code

displayed on the remote controller. In case of a displayed malfunction

code, perform the following actions to correct the abnormality:

■

Error codes on the remote controller when a remote controller is

connected

■

After correcting the abnormality, press the

button

and reset the malfunction code.

■

Carry out the test operation again and confirm that the

abnormality is properly corrected.

Air handling units are not checked by the outdoor unit

during test operation. After the test operation is finished,

check the air handling unit separately with its controller.

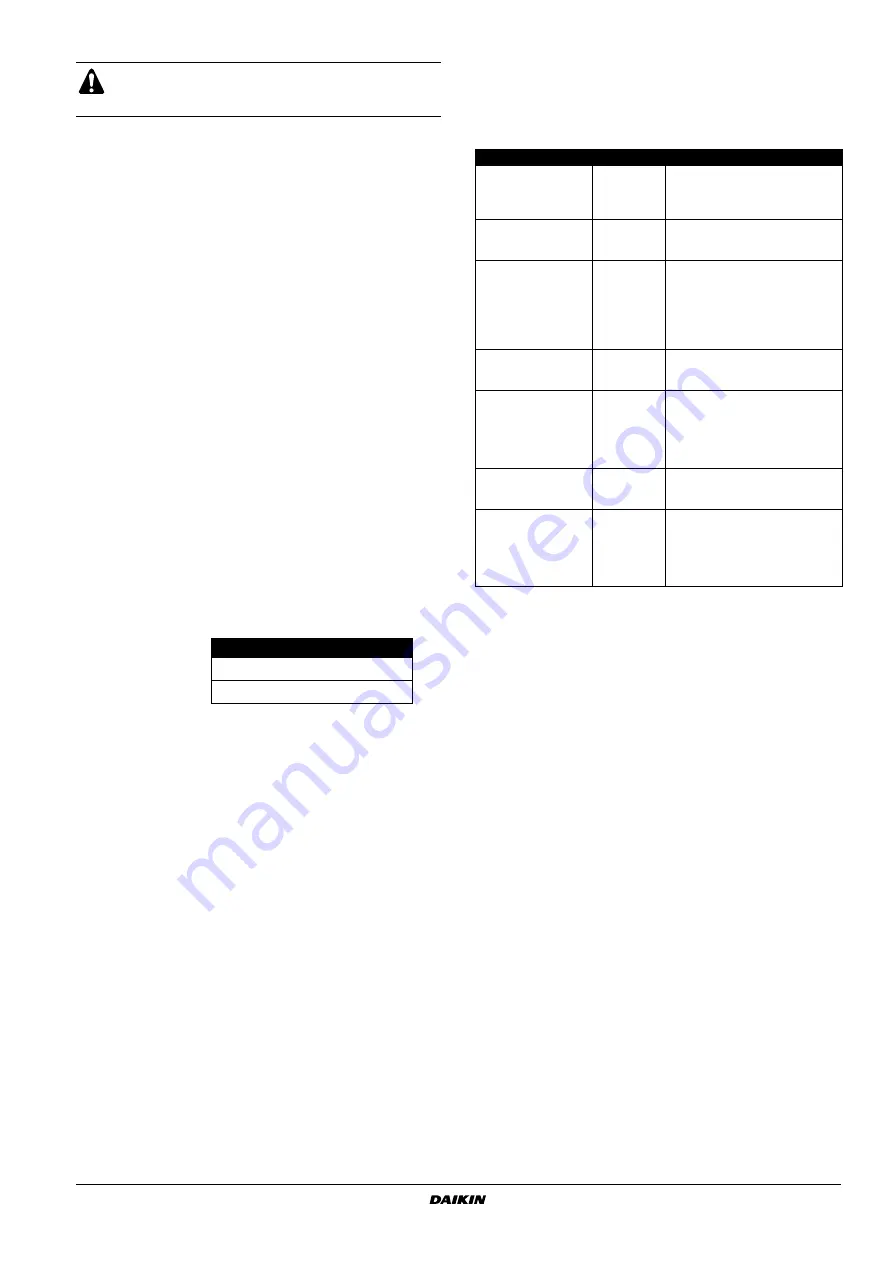

H1P

H2P

H3P

H4P

H5P

H6P

H7P

Normal completion

x

x w x

x

x

x

Abnormal completion

x w w x

x

x

x

BS1 MODE

BS4 TEST

BS3 RETURN

Installation error

Error code

Remedial action

The stop valve of an

outdoor unit is

remained closed.

E3

E4

F3

UF

Check referring to the table in

"Additional refrigerant charge"

The phases of the

power to the outdoor

units are reversed.

U1

Switch two of the three phases (L1,

L2, L3) to make a positive phase

connection.

No power is supplied

to an outdoor or any

other unit (including

phase interruption).

U1

U4

Check if the power wiring for the

outdoor units are connected

correctly.

(If the power wire is not connected

to L2 phase, no malfunction display

will appear and the compressor will

not work.)

Incorrect

interconnections

between units

UF

Check if the refrigerant line piping

and the unit wiring are consistent

with each other.

Refrigerant

overcharge

E3

F6

UF

Recalculate the required amount of

refrigerant from the piping length

and correct the refrigerant charge

level by recovering any excessive

refrigerant with a refrigerant

recovery machine.

The wiring is

connected to the

Q1/Q2 (Out Multi)

U7

UF

Remove the wiring from the Q1/Q2

(Out Multi).

Insufficient refrigerant

E4

F3

Check if the additional refrigerant

charge has been finished correctly.

Recalculate the required amount of

refrigerant from the piping length

and add an adequate amount of

refrigerant.

BS3 RETURN