ERX125~250A7W1B

Inverter condensing unit

4PW30064-1D

Installation manual

5

6.4.

Connecting the refrigerant piping

1

Front connection or side connection

Installation of refrigerant piping is possible as front connection or

side connection (when taken out from the bottom) as shown in

the figure.

2

Removing the pinched piping

When connecting refrigerant piping to the outdoor unit, first

remove the pinched piping. Do not vent gases into the

atmosphere.

Removing of the pinched piping must be carried out according to

the following procedure:

1.

Make sure the stop valves are closed.

2.

Connect a charge hose to the service ports of all stop

valves.

3.

Recover the gas from the pinched piping.

4.

When all the gas is recovered from the pinched piping,

dissolve the brazing using a burner and remove the

pinched piping.

See

3

Piping connections

■

Front connection:

Remove the stop valve cover to connect.

■

Bottom connection:

Remove the knock holes on the bottom frame and route the

piping under the bottom frame.

■

Processing the gas side accessory pipe (2)

Only in case of connecting at lateral side, cut the gas side

accessory pipe (2) as shown in

4

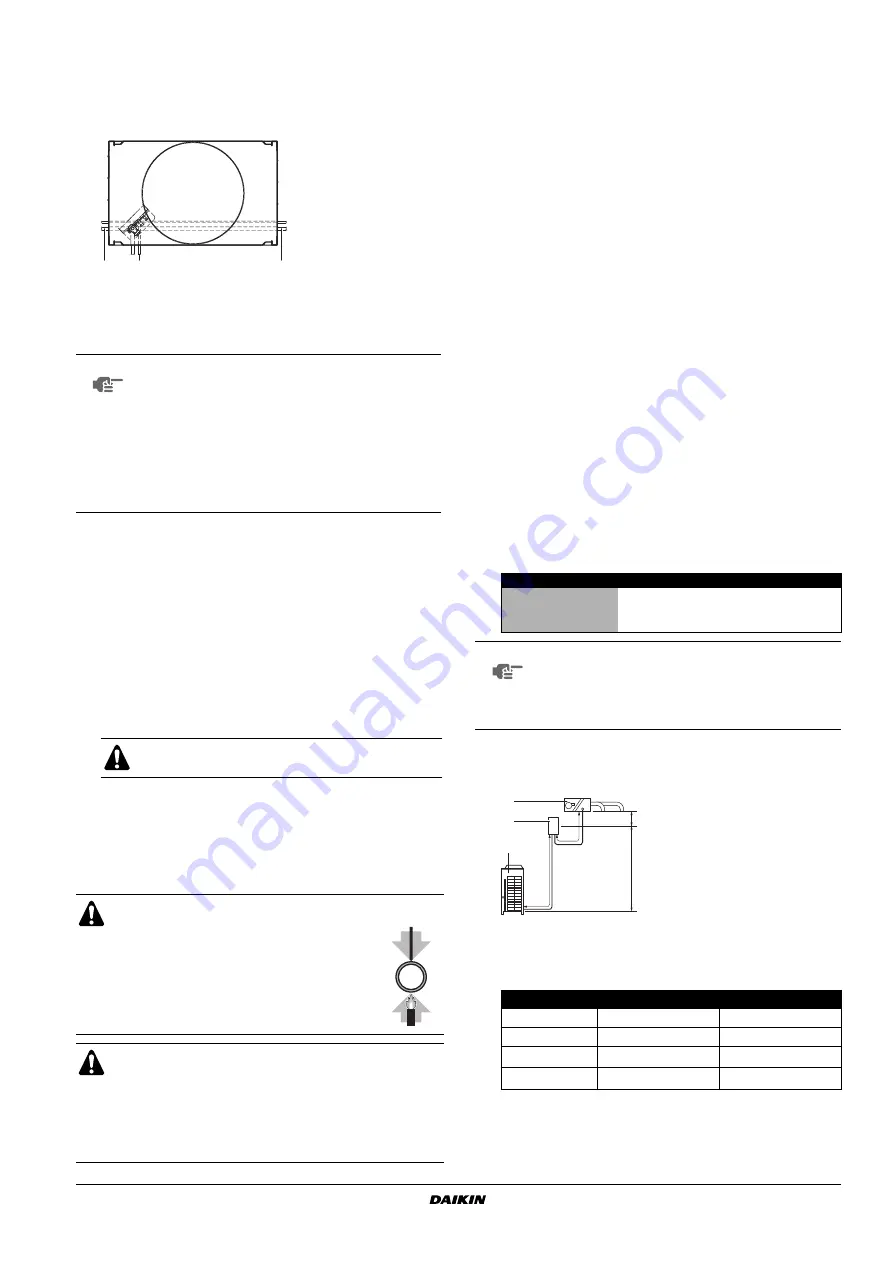

Piping length restrictions

4.1 Installation limitations

1

Left-side connection

2

Front connection

3

Right-side connection

NOTE

Precautions when knocking out knock holes

■

Be sure to avoid damaging the casing

■

After knocking out the holes, we recommend you

remove the burrs and paint the edges and areas

around the edges using the repair paint to prevent

rusting.

■

When passing electrical wiring through the knock

holes, wrap the wiring with protective tape to

prevent damage.

Any gas remaining inside the stop valve may blow off

the pinched piping, causing damage or injury.

1

Pinched piping

2

Stop valve

3

Service port

4

Point of melting the brazing metal

Precautions when connecting field piping.

■

Perform brazing at the gas stop valve

before brazing at the liquid stop valve.

■

Add brazing material as shown in the

figure.

■

Be sure to use the supplied accessory pipes when

carrying out piping work in the field.

■

Be sure that the field installed piping does not touch

other pipes, the bottom panel or side panel. Especially

for the bottom and side connection, be sure to protect

the piping with suitable insulation, to prevent it from

coming into contact with the casing.

1

2

3

A

Front connection

Remove the stop valve cover to connect.

B

Bottom connection:

Remove the knock holes on the bottom frame and route the piping

under the bottom frame

1

Gas side stop valve

2

Liquid side stop valve

3

Service port for adding refrigerant

4

Gas side accessory pipe (1)

5

Gas side accessory pipe (2)

6

Liquid side accessory pipe (1)

7

Liquid side accessory pipe (2)

8

Brazing

9

Gas side piping (field supply)

10

Liquid side piping (field supply)

11

Punch the knockout holes (use a hammer)

1

Gas side accessory pipe

2

Cutting location

3

Gas side piping (field supply)

4

Base

Unit type

A

B

C

D

ERX125

(mm)

166

16

199

246

ERX200

(mm)

156

17

188

247

ERX250

(mm)

156

23

192

247

NOTE

■

When connecting the piping on site, be sure to

use the accessory piping.

■

Make sure the onsite piping does not come into

contact with other piping, the bottom frame or side

panels of the unit.

1

Outdoor unit

2

Valve kit

3

Air handling unit

Max (m)

Min (m)

L1

50

5

L2

5

—

A

–5 / +5

(a)

(a) Below or above the outdoor unit.

—

B

—

L1

L2

A

B

1

2

3