ERX125~250A7W1B

Inverter condensing unit

4PW30064-1D

Installation manual

11

10. C

HECKING

OF

UNIT

AND

INSTALLATION

CONDITIONS

Be sure to check the following:

The piping work

1

Make sure piping size is correct.

See

"6.2. Selection of piping material" on page 4

2

Make sure there is no faulty refrigerant piping.

See

"6. Refrigerant piping" on page 4

3

Make sure insulation work is done.

See

"9. Pipe insulation" on page 10

.

The electrical work

1

Make sure there is no faulty power wiring or loose nuts.

See

2

Make sure there is no faulty transmission wiring or loose nuts.

See

3

Make sure the insulation resistance of the main power circuit is

not deteriorated.

Using a megatester for 500

V, check that the insulation

resistance of 2 M

Ω

or more is attained by applying a voltage of

500 V DC between the power terminals and earth. Never use

the megatester for the transmission wiring (between outdoor

and control box, etc.).

11. C

HARGING

REFRIGERANT

The outdoor unit is factory charged, but depending on the length of

the piping when installed, the outdoor unit may require additional

charging.

For charging the additional refrigerant follow the procedure as

described in this chapter.

11.1. Important information regarding the

refrigerant used

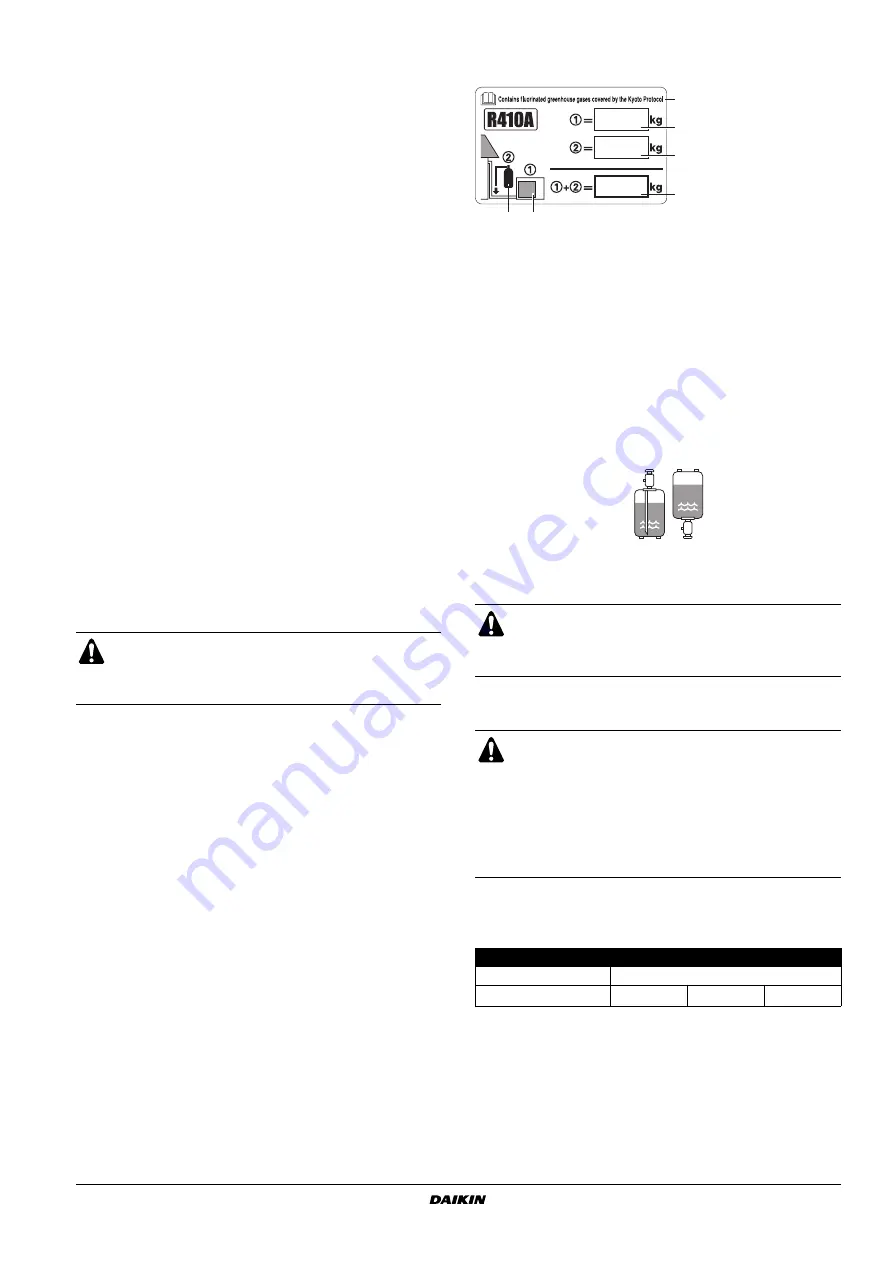

This product contains fluorinated greenhouse gases covered by the

Kyoto Protocol. Do not vent gases into the atmosphere.

Refrigerant type:

R410A

GWP

(1)

value:

1975

(1)

GWP = global warming potential

Please fill in with indelible ink,

■

➀

the factory refrigerant charge of the product,

■

➁

the additional refrigerant amount charged in the field and

■

➀

+

➁

the total refrigerant charge

on the refrigerant charge label supplied with the product.

The filled out label must be adhered in the proximity of the product

charging port (e.g. onto the inside of the service cover).

11.2. Precautions when adding R410A

Be sure to charge the specified amount of refrigerant in liquid state to

the liquid pipe.

Since this refrigerant is a mixed refrigerant, adding it in gas form may

cause the refrigerant composition to change, preventing normal

operation.

■

Before charging, check whether the refrigerant cylinder is

equipped with a siphon tube or not.

■

Be sure to use tools exclusively for R410A to ensure required

pressure resistance and to prevent foreign materials from mixing

into the system.

11.3. Stop valve operation procedure

Size of stop valve

The sizes of the stop valves connected to the system are as listed in

the table below.

Opening stop valve

Refrigerant cannot be charged until all field wiring and field

piping has been completed.

Refrigerant may only be charged after performing the leak

test and the vacuum drying.

Charge the liquid

refrigerant with the

cylinder in upright

position.

Charge the liquid

refrigerant with the

cylinder in up-side-down

position.

Charging with an unsuitable substance may cause

explosions and accidents, so always make sure that the

appropriate refrigerant (R410A) is charged.

Refrigerant containers must be opened slowly.

■

Do not open the stop valve until all piping and

electrical steps of

installation conditions" on page 11

the stop valve is left open without turning on the

power, it may cause refrigerant to build up in the

compressor, leading to insulation degradation.

■

Always use a charge hose for service port connection.

■

After tightening the cap, check that no refrigerant

leaks are present.

Type

125

200

250

Liquid line stop valve

Ø9.5

Gas line stop valve

Ø15.9

Ø19.1

Ø25.4

(a)

(a) The model ERX250 supports field piping of Ø22.2 on the accessory pipe

supplied with the unit.

1

Service port

2

Cap

3

Hexagon hole

4

Shaft

5

Seal

3

5

6

2

1

4

1

factory refrigerant charge

of the product:

see unit name plate

2

additional refrigerant

amount charged in the

field

3

total refrigerant charge

4

Contains fluorinated

greenhouse gases

covered by the Kyoto

Protocol

5

outdoor unit

6

refrigerant cylinder and

manifold for charging