Installation manual

16

ERX125~250A7W1B

Inverter condensing unit

4PW30064-1D

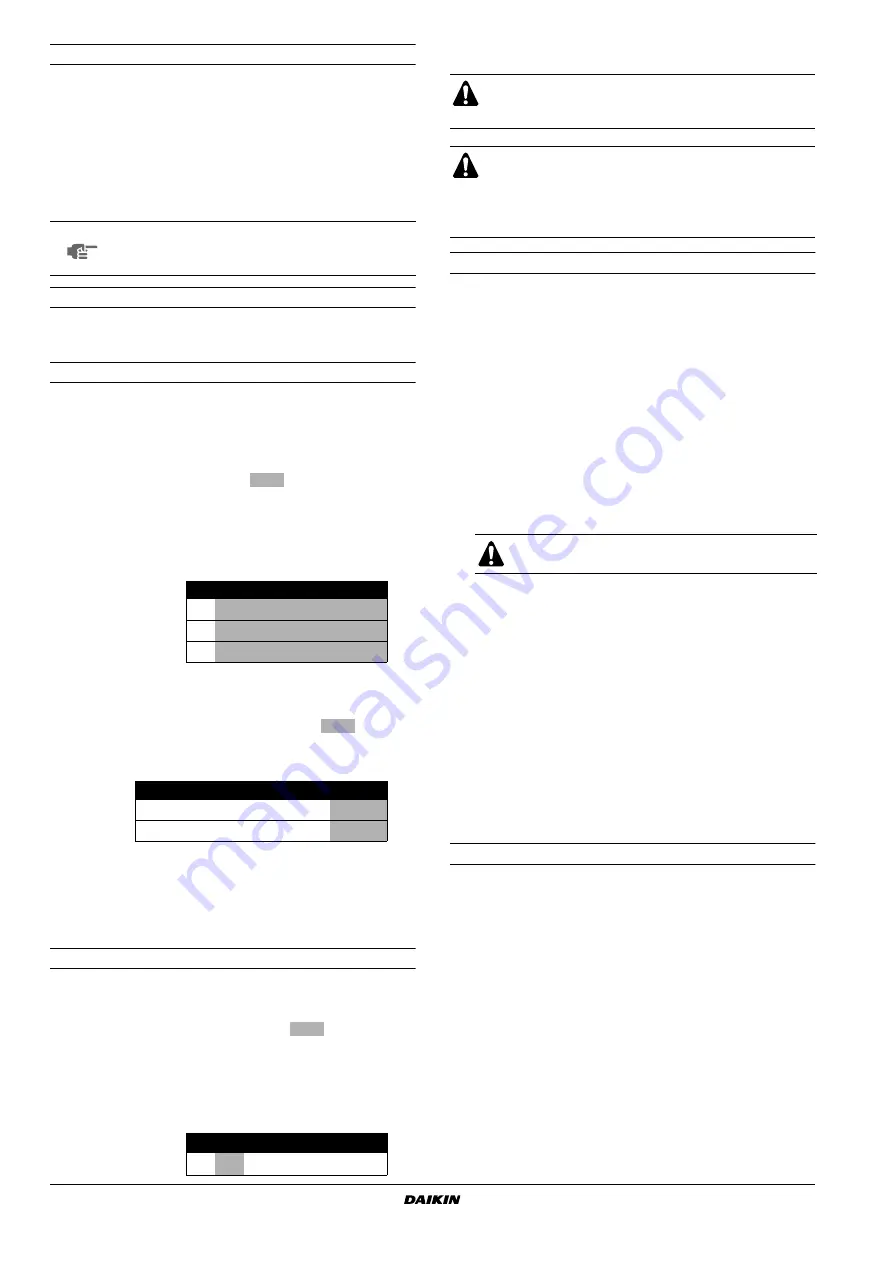

Setting the mode

The set mode can be changed with the

button according

to the following procedure:

■

For setting mode 1: Press the

button once, the

H1P LED is off

x

.

■

For setting mode 2: Press the

button for

5 seconds, the H1P LED is on

w

.

If the H1P LED is blinking

c

and the

button is pushed

once, the setting mode will change to setting mode 1.

Mode 1

This mode is not used for adjusting settings, it is only used for

confirmation of the set mode. The H1P LED is off.

Setting mode 2

The H1P LED is on.

Setting procedure

1

Push the

button according to the required function

(A~C). The LED indication that matches the required function is

shown below in the field marked

:

2

When the

button is pushed, the current setting is

defined.

3

Push the

button according to the required setting

possibility as shown below in the field marked

.

3.1 Possible settings for function A, B, and C are

(ON) or

(OFF).

4

Push the

button and the setting is defined.

5

When the

button is pushed again, the operation

starts according to the setting.

Refer to the service manual for more details and for other settings.

Confirmation of the set mode

The following item can be confirmed by setting mode 1 (H1P

LED is off)

Check the LED indication in the field marked

.

Indication of the present operation state

-

x

, normal

-

w

, abnormal

-

c

, under preparation or under test operation

12.4. Test operation

In case refrigerant was added in cooling mode

■

In the check operation, the following checks and judgement will

be performed:

■

Check of the stop valve opening

■

Check for wrong wiring

■

Judgement of piping length

■

It takes ±30 minutes to complete the check operation.

Check operation procedure

1

Close the electric box lid and all front panels except the one on

the side of the electric box.

2

Turn on the power to the outdoor unit. Turn the power on on all

connected control boxes and air handling units. Be sure to turn

the power ON at least 6 hours before operation in order to have

power running to the crank case heater.

3

Make the field setting as needed using the push buttons on the

PCB (A1P) of the outdoor unit. Refer to

4

Set the check operation (without initial refrigerant decision)

following setting mode 2 in the field setting and perform the

check operation.

The system operates for ±30 minutes and automatically stops

the check operation.

■

If no malfunction code is displayed on the remote controller

after the system has stopped, check if the operation is

completed. Normal operation will be possible after 5 minutes.

■

If a malfunction code is displayed on the remote controller,

correct the malfunction and perform the check operation

again as described in

"Correcting after abnormal completion

of the test operation" on page 17

In case refrigerant was added at standstill

■

In the check operation, the following checks and judgement will

be performed:

■

Check of the stop valve opening

■

Check for wrong wiring

■

Check of refrigerant overcharge

■

Judgement of piping length

■

It takes ±40 minutes to complete the check operation.

Perform the test operation as described in the paragraph

operation procedure" on page 17

NOTE

If you get confused in the middle of the setting

process, push the

button. Then it returns to

setting mode 1 (H1P LED is off).

Possible functions

A

additional refrigerant charging operation.

B

refrigerant recovery operation/vacuuming operation.

C

setting of high static pressure.

H1P

H2P

H3P

H4P

H5P

H6P

H7P

A

w x w x w x

x

B

w x w x w x w

C

w x w x

x w x

H1P

H2P

H3P

H4P

H5P

H6P

H7P

w x

x

x

x c x

(a)

(a) This setting = factory setting

w x

x

x

x

x c

H1P

H2P

H3P

H4P

H5P

H6P

H7P

x

x w x

x

x

x

BS1 MODE

BS1 MODE

BS1 MODE

BS1 MODE

BS1 MODE

BS2 SET

BS3 RETURN

BS2 SET

ON

OFF

ON

OFF

BS3 RETURN

BS3 RETURN

Do not insert fingers, rods or other objects into the air

inlet or outlet. When the fan is rotating at high speed, it

will cause injury.

Do not perform the test operation while working on the

units.

When performing the test operation, not only the outdoor

unit, but the connected units will operate as well. Working

on a unit while performing a test operation is dangerous.

Make sure that the fan of the air handling unit is

operating before starting the test operation.