ERX125~250A7W1B

Inverter condensing unit

4PW30064-1D

Installation manual

3

4.

I

NSPECTING

AND

HANDLING

THE

UNIT

At delivery, the package should be checked and any damage should

be reported immediately to the carrier claims agent.

When handling the unit, take into account the following:

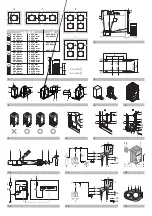

1

Fragile, handle the unit with care.

Keep the unit upright in order to avoid compressor

damage.

2

Choose on beforehand the path along which the unit is to be

brought in.

3

Bring the unit as close as possible to its final installation position

in its original package to prevent damage during transport.

4

Lift the unit preferably with a crane and 2 belts of at least 8 m

long.

Always use protectors to prevent belt damage and pay attention

to the position of the unit's centre of gravity.

5

If a forklift is to be used, preferably transport the unit with pallet

first, then pass the forklift arms through the large rectangular

openings on the bottom of the unit.

5.1 From the moment you use a forklift to move the unit to its final

position, lift the unit under the pallet.

5.2 Once at final position, unpack the unit and pass the forklift arms

through the large rectangular openings on the bottom of the unit.

5.

U

NPACKING

AND

PLACING

THE

UNIT

■

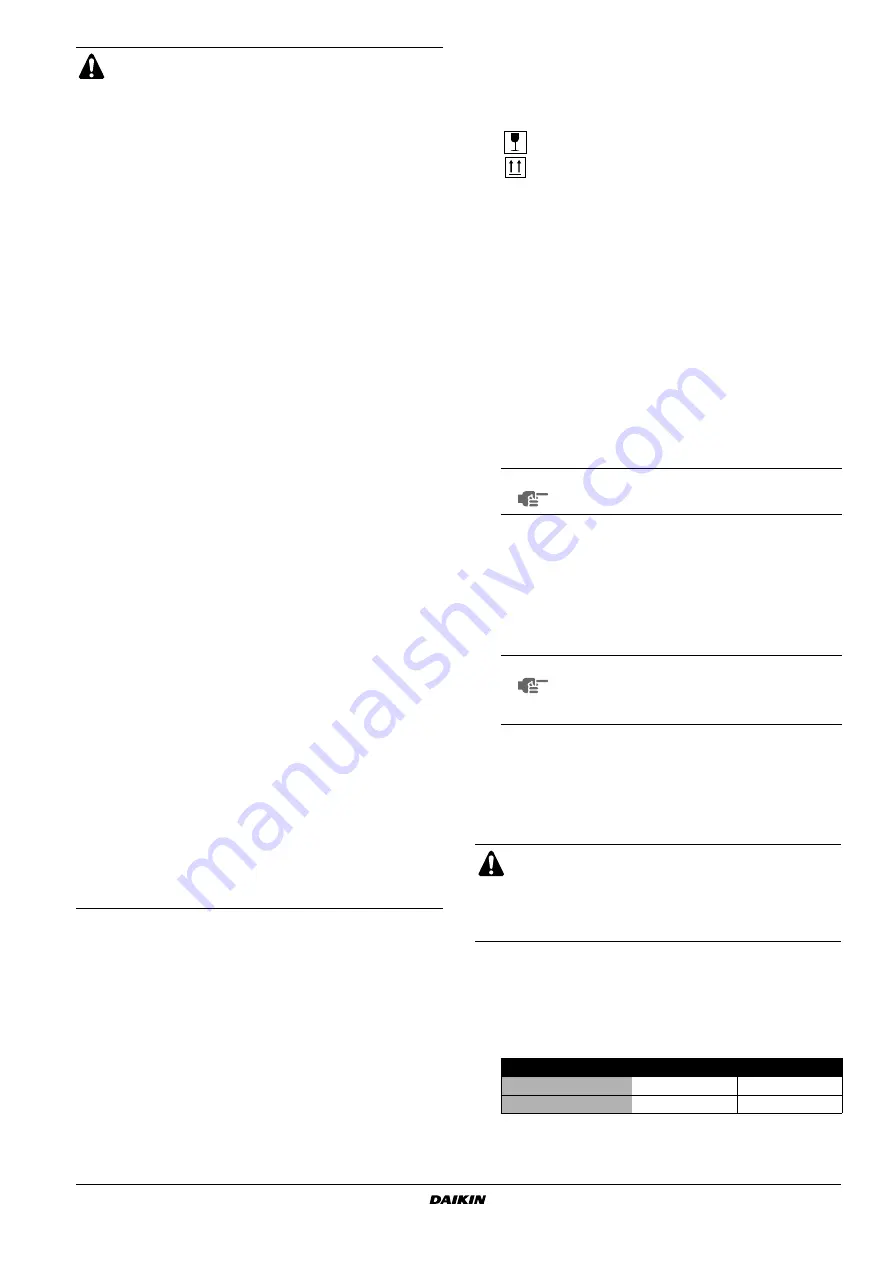

Remove the four screws fixing the unit to the pallet.

■

Make sure the unit is installed level on a sufficiently strong base

to prevent vibration and noise.

■

Make sure the base under the unit is larger than the 765 mm of

the unit depth.

■

The height of the foundation must at least be 150 mm from the

floor.

■

The unit must be installed on a solid longitudinal foundation

(steelbeam frame or concrete) as indicated in

■

The equipment described in this manual may cause

electronic noise generated from radio-frequency

energy. The equipment complies to specifications that

are designed to provide reasonable protection against

such interference. However, there is no guarantee that

interference will not occur in a particular installation.

It is therefore recommended to install the equipment

and electric wires keeping proper distances away from

stereo equipment, personal computers, etc...

.

In places with weak reception, keep distances of 3 m

or more to avoid electromagnetic disturbance of other

equipment and use conduit tubes for power and

transmission lines.

■

In heavy snowfall areas, select an installation site

where snow will not affect the operation of the unit.

■

The refrigerant R410A itself is nontoxic, nonflammable

and is safe. If the refrigerant should leak however, its

concentration may exceed the allowable limit

depending on room size. Due to this, it could be

necessary to take measures against leakage. Refer to

the chapter

"14. Caution for refrigerant leaks" on

■

Do not install in the following locations.

•

Locations where sulfurous acids and other

corrosive gases may be present in the atmosphere.

Copper piping and soldered joints may corrode,

causing refrigerant to leak.

•

Locations where a mineral oil mist, spray or vapour

may be present in the atmosphere.

Plastic parts may deteriorate and fall off or causing

water leakage.

•

Locations where equipment that produces electro-

magnetic waves is found.

The electromagnetic waves may cause the control

system to malfunction, preventing normal

operation.

•

Locations where flammable gases may leak, where

thinner, gasoline, and other volatile substances are

handled, or where carbon dust and other

incendiary substances are found in the

atmosphere.

Leaked gas may accumulate around the unit,

causing an explosion.

■

When installing, take strong winds, typhoons or

earthquakes into account.

Improper installation may result in fall over of the unit.

1

Personal computer or radio

2

Fuse

3

Earth leakage breaker

4

Controller

5

Air handling unit

1

Packaging material

2

Opening (large)

3

Belt sling

4

Opening (small) (40x45)

5

Protector

NOTE

Use a belt sling of

≤

20 mm wide that adequately

bears the weight of the unit.

NOTE

Use filler cloth on the forklift arms to prevent

damaging the unit. If the paint on the bottom

frame peels off, the anti corrosion effect may

decrease.

Do not use stands to only support the corners.

Model

A

B

ERX125

635

497

250

930

792

X

Not allowed (except for ERX125)

O

Allowed (units: mm)