ESIE13-02

Error Codes: Gas Condensing Boiler

87

Part 4 – Troubleshooting

4

3

4

5

4

2.3

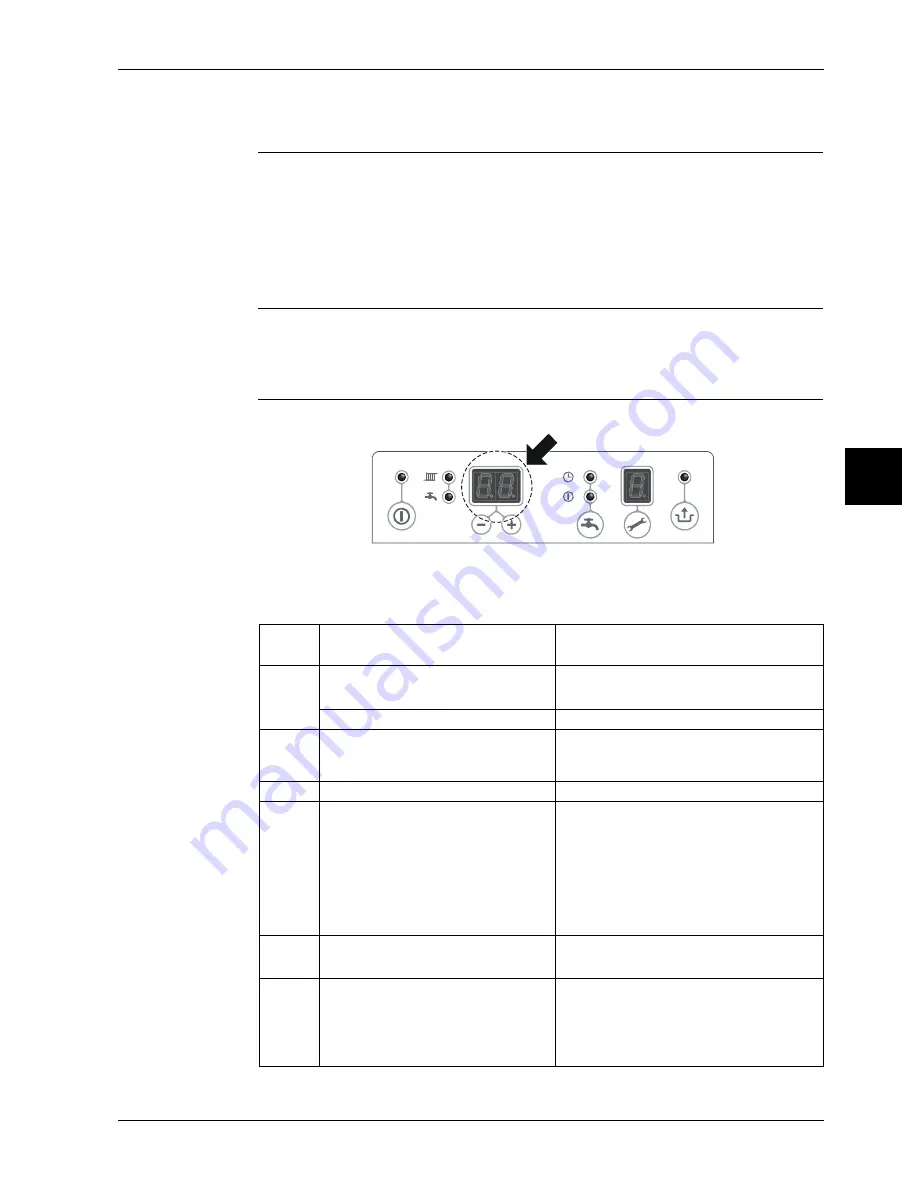

Solving Problems Based on Error Codes

When a problem happens, an error code appears on the user interface. It is important to understand

the problem and to take countermeasure before resetting the error code. This should be done by a

licensed installer or by your local dealer.

This chapter gives you an overview of all error codes and the content of the error code as it appears

on the user interface.

For a more detailed troubleshooting guideline for each error, please see the service manual.

2.3.1

Error codes: Overview

Error codes of the

gas boiler

The controller on the gas boiler detects faults and indicates them on the display by error codes.

If the LED is flashing, the controller has detected a problem. Once the problem is rectified, the

controller can be restarted by pressing the

f

button.

Following table shows a list of error codes and the possible solutions.

Error

code

Cause

Possible solution

10, 11,

12, 13,

14

Sensor fault S1.

Check wiring.

Replace S1.

Flow sensor cannot close.

Check flow switch.

20, 21,

22, 23,

24

Sensor fault S2.

Check wiring.

Replace S2.

0

Sensor fault after self-check.

Replace S1 and/or S2.

1

Temperature too high.

Air in installation.

Pump is NOT running.

Insufficient flow in installation.

Radiators are closed.

Pump setting is too low.

Flow switch is sticking.

2

S1 and S2 interchanged.

Check cable set.

Replace S1 and S2.

4

No flame signal.

Gas tap is closed.

No or incorrect ignition gap.

Gas supply pressure is too low or fails.

Gas valve or ignition unit is NOT powered.