15

|

Disposal

Installer reference guide

269

EPRA14~18D + ETSH/X(B)16P30+50E

Daikin Altherma 3 H HT ECH₂O

4P679467-1C – 2023.07

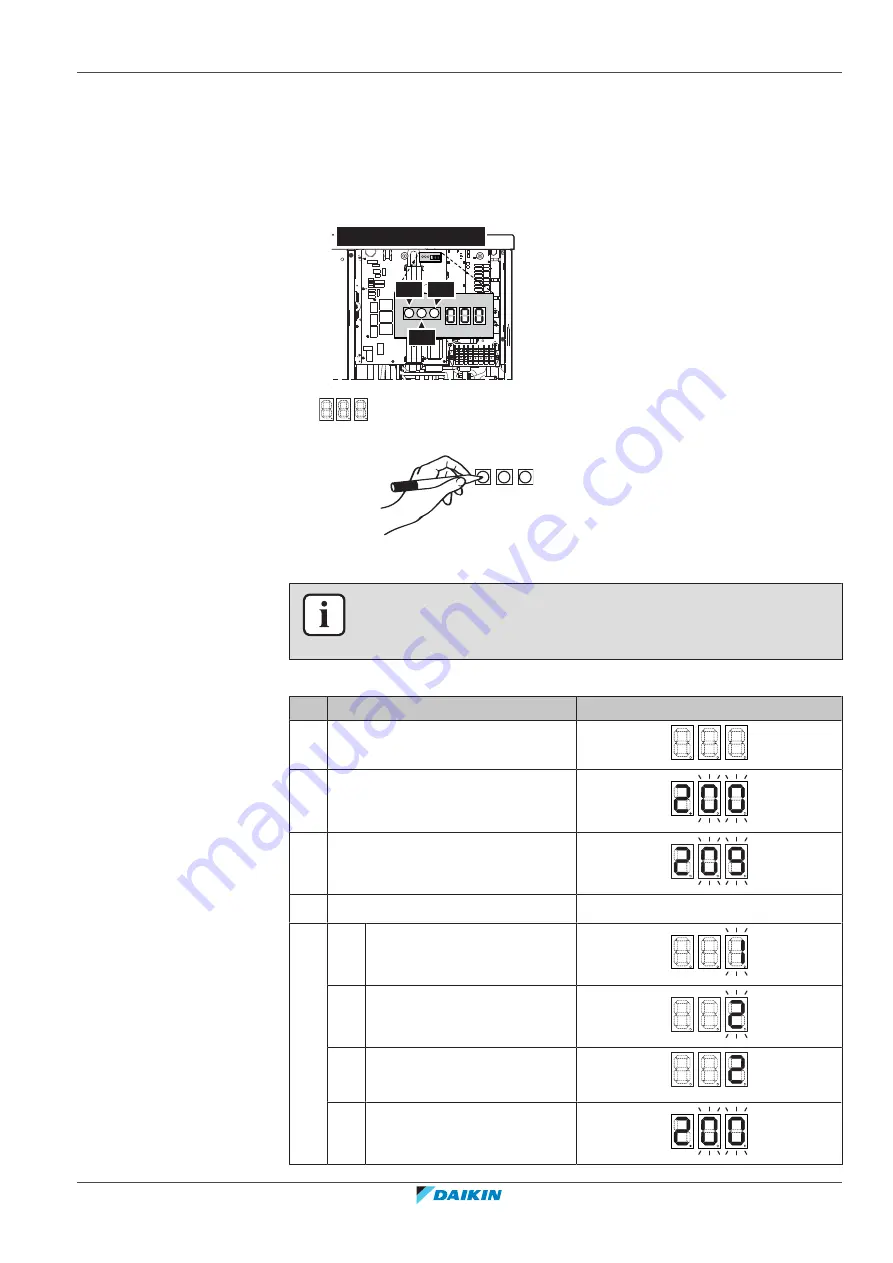

15.1.3 Recovery mode — In case of EPRA-DBW1* models (7-segments display)

Before recovering refrigerant, make sure the electronic expansion valves are open.

When power is ON, this has to be done by using the recovery mode.

Components

To activate/deactivate the recovery mode, you need the following components:

BS1 BS3

BS2

EPRA-DBW1*

7‑segments display

BS1~BS3

Push buttons. Operate the push buttons with an insulated stick (such as a closed

ballpoint pen) to avoid touching of live parts.

To activate the recovery mode

INFORMATION

If you get confused in the middle of the process, press BS1 to return to the default

situation.

Before recovering refrigerant, activate the recovery mode as follows:

#

Action

7-segments display

(a)

1

Start from the default situation.

2

Select mode 2.

Press and hold

BS1

for 5 seconds.

3

Select setting 9.

Press

BS2

9 times.

4

Select value 2.

a

Display the current value.

Press

BS3

once.

b

Change the value to 2.

Press

BS2

once.

c

Enter the value in the system.

Press

BS3

once.

d

Confirm.

Press

BS3

once.

Summary of Contents for ETSXB16E

Page 313: ......

Page 314: ......

Page 315: ......

Page 316: ...4P679467 1C 2023 07 Copyright 2022 Daikin Verantwortung f r Energie und Umwelt...