Installation and operation manual

15

EUWAC5~10FZ

Packaged air-cooled water chillers

4PW14037-1D

M

AINTENANCE

In order to ensure optimal availability of the unit, a number of checks

and inspections on the unit and the field wiring have to be carried out

at regular intervals.

If the unit is used for air conditioning application, the described

checks should be executed at least once a year. In case the unit is

used for other applications, the checks should be executed every 4

months.

Important information regarding the refrigerant used

This product contains fluorinated greenhouse gases covered by the

Kyoto Protocol.

Refrigerant type:

R407C

GWP

(1)

value:

1652.5

(1)

GWP = global warming potential

Periodical inspections for refrigerant leaks may be required

depending on European or local legislation. Please contact your local

dealer for more information.

Maintenance activities

1

Condenser coil

Remove dust and any other contaminant from the coil fins using

a brush and a blower. Blow from the inside of the unit. Take care

not to bend or damage the fins.

2

Field wiring and power supply

■

Check the power supply voltage on the local supply panel.

The voltage should correspond to the voltage marked on the

identification label of the unit.

■

Check the connections and make sure they are properly

fixed.

■

Check the proper operation of the circuit breaker and the

earth leak detector provided on the local supply panel.

3

Internal wiring of the unit

Visually check the switch box on loose connections (terminals

and components). Make sure that the electrical components are

not damaged or loose.

4

Earth connection

Make sure that the earth wires are still connected properly and

that the earth terminals are tightened.

5

Refrigerant circuit

■

Check for leaks inside the unit. In case a leak is detected, call

your local Daikin dealer.

■

Check the working pressure of the unit. Refer to paragraph

in the chapter “

6

Compressor

■

Check on oil leaks. If there is an oil leak, call your local Daikin

dealer.

■

Check for abnormal noises and vibrations. If the compressor

is damaged, call your local Daikin dealer.

7

Condenser fan motor

■

Clean the cooling ribs and the cooling grid of the motor.

■

Check on abnormal noises. If the fan or motor are damaged,

call your local Daikin dealer.

8

Air in/outlet ducts of unit

■

Clean the inside of the ducting (use a vacuum cleaner, avoid

dirt and dust from entering the condenser coil).

■

Check if the ducts are properly fixed and do not make contact

with the unit (may cause abnormal noises or vibrations).

■

Make sure that the flexible connection between the ducts and

the unit is not damaged or perforated. Replace it if

necessary.

9

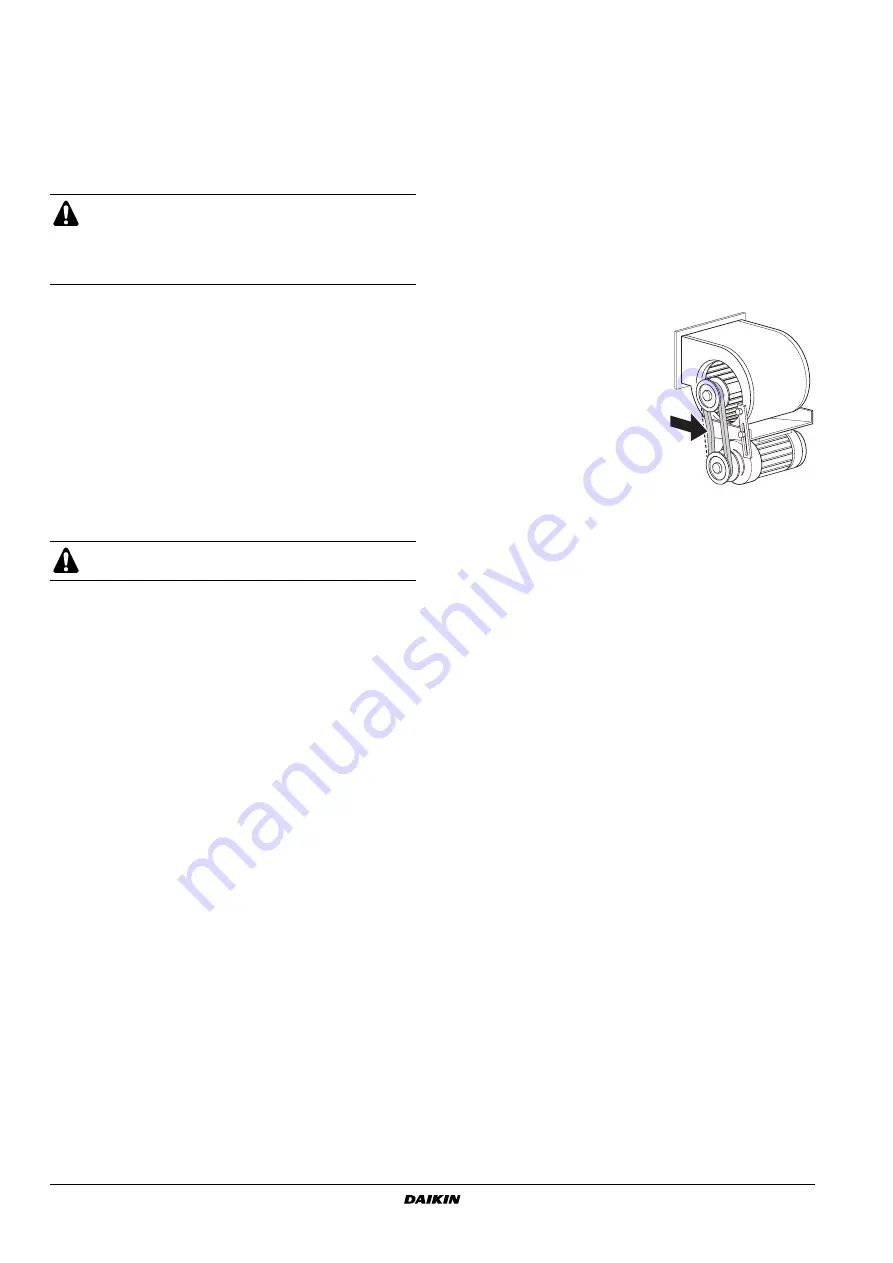

V-belt transmission of condenser fan motor

(for 10 units only)

■

Check that the V-belt is not worn

out. Replace if necessary.

■

Check the tension of the V-belt.

When the belt is slightly

pressed with the fingers, the

relaxation of the belt may not

exceed 10 mm.

10

Water supply

■

Check if the water connection is still well fixed.

■

Check the water quality (refer to the chapter “

” for specifications of the water quality).

11

Drain disposal

■

Check the proper functioning of the drain. Make sure that

water evacuates freely. Clean the drain pan and piping

thoroughly.

Disposal requirements

Dismantling of the unit and treatment of the refrigerant, oil and even-

tual other parts, should be done in accordance with the relevant local

and national regulations.

Before carrying out any maintenance or repair activity,

always switch off the circuit breaker on the supply panel,

remove the fuses or open the protection devices of the

unit.

Do never clean the unit with water under pressure.

The wiring and power supply must be checked by a

licensed electrician.

Summary of Contents for EUWAC8FZW1

Page 22: ...4PW14037 1D Copyright Daikin...