Piping Layout

ESIE11-02

1–62

3

11

4

5

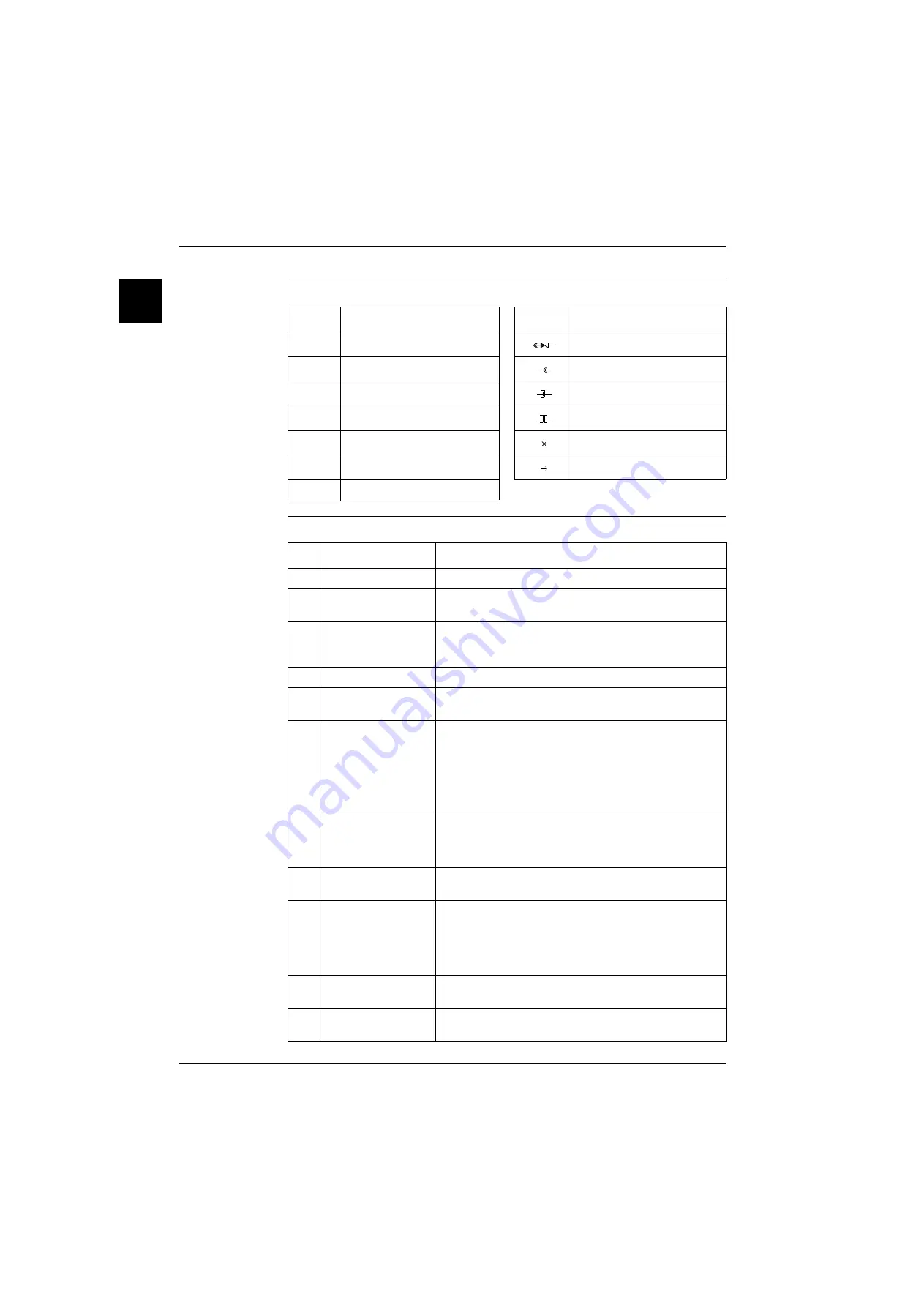

Symbols

The table below describes the symbols.

Components

refrigeration side

The table below describes the main components of the refrigeration circuit on the refrigeration side.

Symbol

Description

Symbol

Description

R3T

Inlet water temperature sensor

Check valve

R4T

Outlet water temperature sensor

Flare connection

R6T

Ambient temperature sensor

Screw connection

S*HP

High-pressure switch

Flange connection

S*LP

Low-pressure switch

Pinched pipe

M*F

Condensor fan

Spinned pipe

M*C

Compressor

No.

Component

Function / remark

1

Compressor

A hermetically sealed scroll compressor.

2

Water-heat exchanger

(evaporator)

The water-heat exchanger is of the brazed plate-heat

exchanger type.

3

Air-heat exchanger

(condensor)

The air-heat exchanger is of the cross fin coil type. Hi-X-tubes

and PE coated waffle louvre fins are used. The air is discharged

upwards.

4

Fan

Direct driven single or two speed motor.

5

Expansion valve

The thermostatic expansion valve is set up to control the

superheat between 5°C and 7°C.

6

Low-pressure switch

This switch acts as a circuit safety.

■

Standard setting: OFF = 2 bar ± 0.3

■

Standard setting: ON = 0.2 bar ± 0.2

■

Glycol application setting: OFF = 1.5 bar ± 0.3

■

Glycol application setting: ON = 0.5 bar ± 0.2

7

High-pressure switch

This switch acts as a circuit safety.

■

Standard setting: OFF = 21.6 bar +0/-1

■

Standard setting: ON = 30.9 bar +0/-1

8

Strainer

This strainer prevents dirt particles from entering the expansion

valve.

9

Water in- and outlet

connections

The water in- and outlet connections are made of galvanized

steel pipe (British Standard Pipe - BSP). The pipes are not

insulated.

If copper field piping is used for the water circuit, then precau-

tion should be taken to prevent electrolytic corrosion.

10

Low-pressure

service port

The low-pressure service port is used to connect a

low-pressure gauge.

11

High-pressure

service port

The high-pressure service port is used to connect a

high-pressure gauge.

Summary of Contents for EUWY 24KBZW1 Series

Page 2: ......

Page 8: ...ESIE11 02 vi Table of Contents 3 1 4 5...

Page 10: ...Introduction ESIE11 02 viii 3 1 4 5...

Page 12: ...ESIE11 02 1 2 Part 1 System Outline 3 1 1 5...

Page 86: ...Wiring Layout ESIE11 02 1 76 Part 1 System Outline...

Page 88: ...ESIE11 02 2 2 Part 2 Functional Description 3 1 2 5...

Page 128: ...The Digital Controller ESIE11 02 2 42 Part 2 Functional Description 3 1 2 4 5...

Page 130: ...ESIE11 02 3 2 Part 3 Troubleshooting 3 1 3 5...

Page 168: ...ESIE11 02 4 2 Part 4 Commissioning and Test Run 3 1 4 5...

Page 198: ...Test Run and Operation Data ESIE11 02 4 32 Part 4 Commissioning and Test Run 3 1 4 5...

Page 200: ...ESIE11 02 5 2 Part 5 Maintenance 3 1 5...

Page 210: ...ESIE11 02 4 Index 3 1 4 5...