D-EIMAC00208-16EU - 13/192

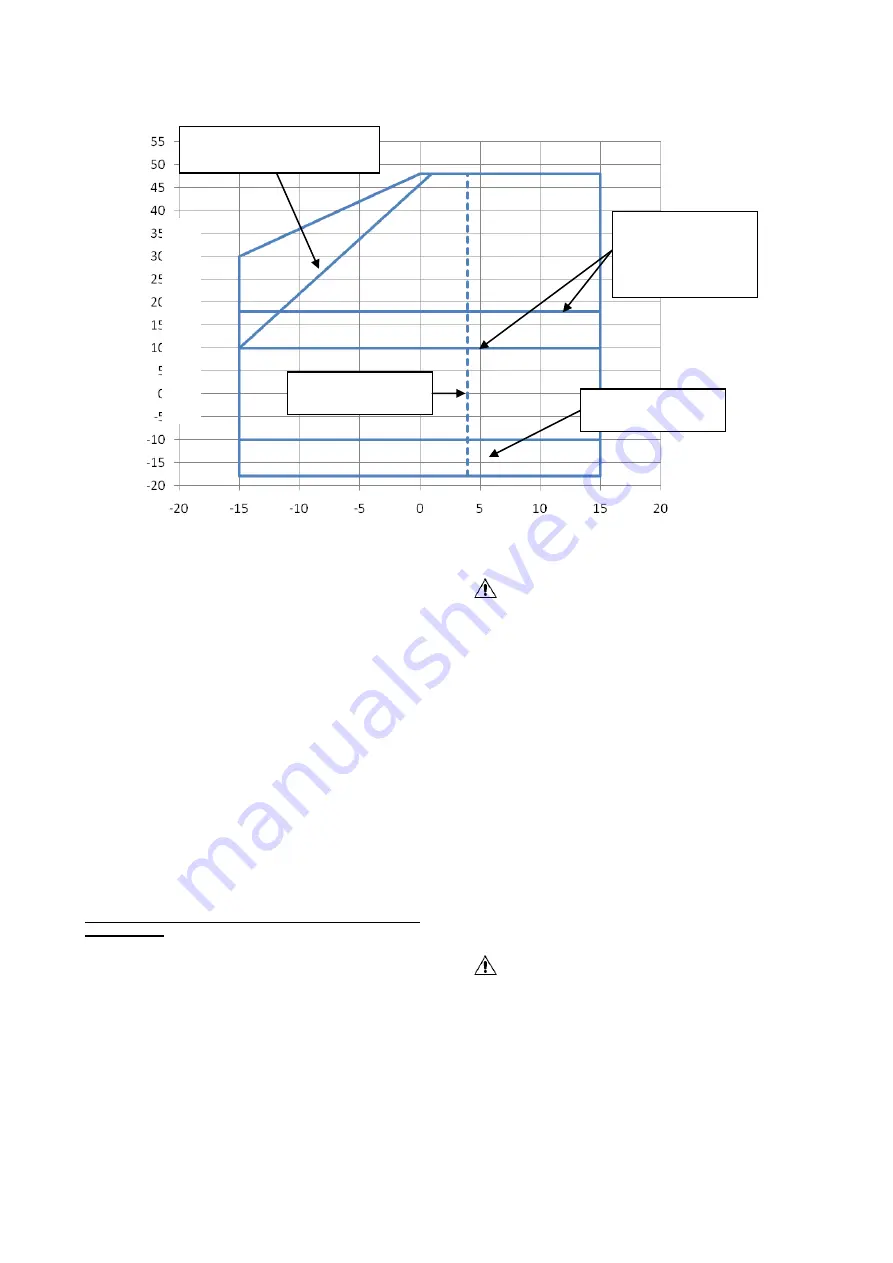

Figure 2 - Operating limits

Safety

The unit must be firmly secured to the soil.

It is essential to observe the following instructions:

The unit can only be lifted using the lifting points marked

in yellow fixed to its base.

It is forbidden to access the electrical components without

having opened the unit main switch and switched off the

power supply.

It is forbidden to access the electrical components without

using an insulating platform. Do not access the electrical

components if water and/or moisture are present.

Sharp edges and the surface of the condenser section

could cause injury. Avoid direct contact and use adeguate

protection device

Switch off power supply, by opening the main switch,

before servicing the cooling fans and/or compressors.

Failure to observe this rule could result in serious

personal injury.

Do not introduce solid objects into the water pipes while

the unit is connected to the system.

A mechanical filter must be installed on the water pipe

connected to the heat exchanger inlet.

The unit is supplied with safety valves, that are installed

both on the high-pressure and on the low-pressure sides

of the refrigerant circuit.

It is absolutely forbidden to remove all protections of

moving parts.

In case of sudden stop of the unit, follow the instructions on the

Control Panel Operating Manual

which is part of the on-

board documentation delivered to the end user.

It is strongly recommended to perform installation and

maintenance with other people. In case of accidental injury or

unease, it is necessary to:

-

keep calm

-

press the alarm button if present in the installation site

-

move the injured person in a warm place far from the unit

and in rest position

-

contact immediately emergency rescue personnel of the

building or the Health Emergency Service

-

wait without leaving the injured person alone until the

rescue operators come

-

give all necessary information to the the rescue operators

Avoid installing the chiller in areas that could be

dangerous during maintenance operations, such as

platforms without parapets or railings or areas not

complying with the clearance requirements around the

chiller.

Noise

The unit is a source of noise mainly due to rotation of

compressors and fans.

The noise level for each model size is listed in sales

documentation.

If the unit is correctly installed, operated and manteined the

noise emission level do not require any special protection

device to operate continuosly close to the unit without any risk.

In case of installation with special noise requirements it could

be necessary to install additional sound attenuation devices.

Moving and lifting

Avoid bumping and/or jolting during loading/unloading unit

from the truck and moving it. Do not push or pull the unit from

any part other than the base frame. Secure the unit inside the

truck to prevent it from moving and causing damages. Do not

allow any part of the unit to fall during transportation or

loading/unloading.

All units of the are supplied with lifting points marked in yellow.

Only these points may be used for lifting the unit, as shown in

the following Figure 3.

Both the lifting ropes and the spacing bars must be

strong enough to support the unit safely. Please check

the unit’s weight on the unit nameplate.

The unit must be lifted with the utmost attention and care

following lifting label instructions; lift unit very slowly, keeping it

perfectly level..

Positioning and assembly

All units are designed for installation outdoors, either on

balconies or on the ground, provided that the installation area

is free of obstacles that could reduce air flow to the

condensers coil.

Evap Leaving Water Temperature (°C)

A

m

b

ie

n

t

T

e

m

p

e

ra

tu

re

(

°C

)

Speedtroll required

(below -10°C Amb.)

Fan Speed Modulation

required

(below 18°C Amb. Temp

for less than 3 fans units,

below 10°C for 3 or more

fans units)

COMP FULL LOAD ONLY

Above this line

(ICE Mode)

Operation with Glycol

(below 4°C Evap LWT)

Summary of Contents for EWAD-D-H 200

Page 3: ...D EIMAC00208 16EU 3 192 A B...

Page 8: ...D EIMAC00208 16EU 8 192 A B...

Page 66: ...D EIMAC00208 16EU 66 192 chiller chiller Carnot DOC 20 57 95 1 1 6 2 7 3 8 4 9 5...

Page 67: ...D EIMAC00208 16EU 67 152 2 chiller chiller 3Figure 3 C C Speedtroll 10 C 18 C 3 10 C 3 ICE 4 C...

Page 69: ...D EIMAC00208 16EU 69 192 4 7 8 25 C 9 10...

Page 74: ...EIMAC00208 16EU 74 192...

Page 84: ...D EIMAC00208 16EU 84 192 20 C 57 95 1 1 6 2 7 3 8 4 9 5...

Page 85: ...D EIMAC00208 16EU 85 192 2 3Figure 3 C C Speedtroll 10 C 18 C 3 10 C 3 ICE 4 C...

Page 86: ...D EIMAC00208 16EU 86 192 3 250 2500 3000 3600 1 2 3 4 5 6 2355 4 0 0 0 2400 2234 L...

Page 87: ...D EIMAC00208 16EU 87 192 4 7 8 25 C 9 10 11 12...

Page 91: ...EIMAC00208 16EU 91 192 1 1 2 3 1 2 3 x 1000 a b c d e f g h CO2 m n GWP p 2 CO2 x 1000...

Page 92: ...EIMAC00208 16EU 92 192 4 3...

Page 174: ...D EIMAC00208 16EU 174 192 DOC 20 C 57 C 95 1 1 6 2 7 3 8 4 9 5...

Page 175: ...D EIMAC00208 16EU 175 162 2 3Figure3 C Temperatura ambiente C 10 C 18 C 3 10 C 3 ICE 4 C...

Page 176: ...D EIMAC00208 16EU 176 192 3 250 2500 3000 3600 1 2 3 4 5 6 2355 4 0 0 0 2400 2234 L...

Page 177: ...D EIMAC00208 16EU 177 192 4 7 8 25 C 9 10 11 12...

Page 181: ...EIMAC00208 16EU 181 192 1 1 2 3 1 2 3 1000 CO2 2 CO2 1000...

Page 182: ...EIMAC00208 16EU 182 192 Intergovernmental Panel on Climate Change IPCC IPCC...