General Outline

ESIE10-01

1–52

3

11

4

5

1.21

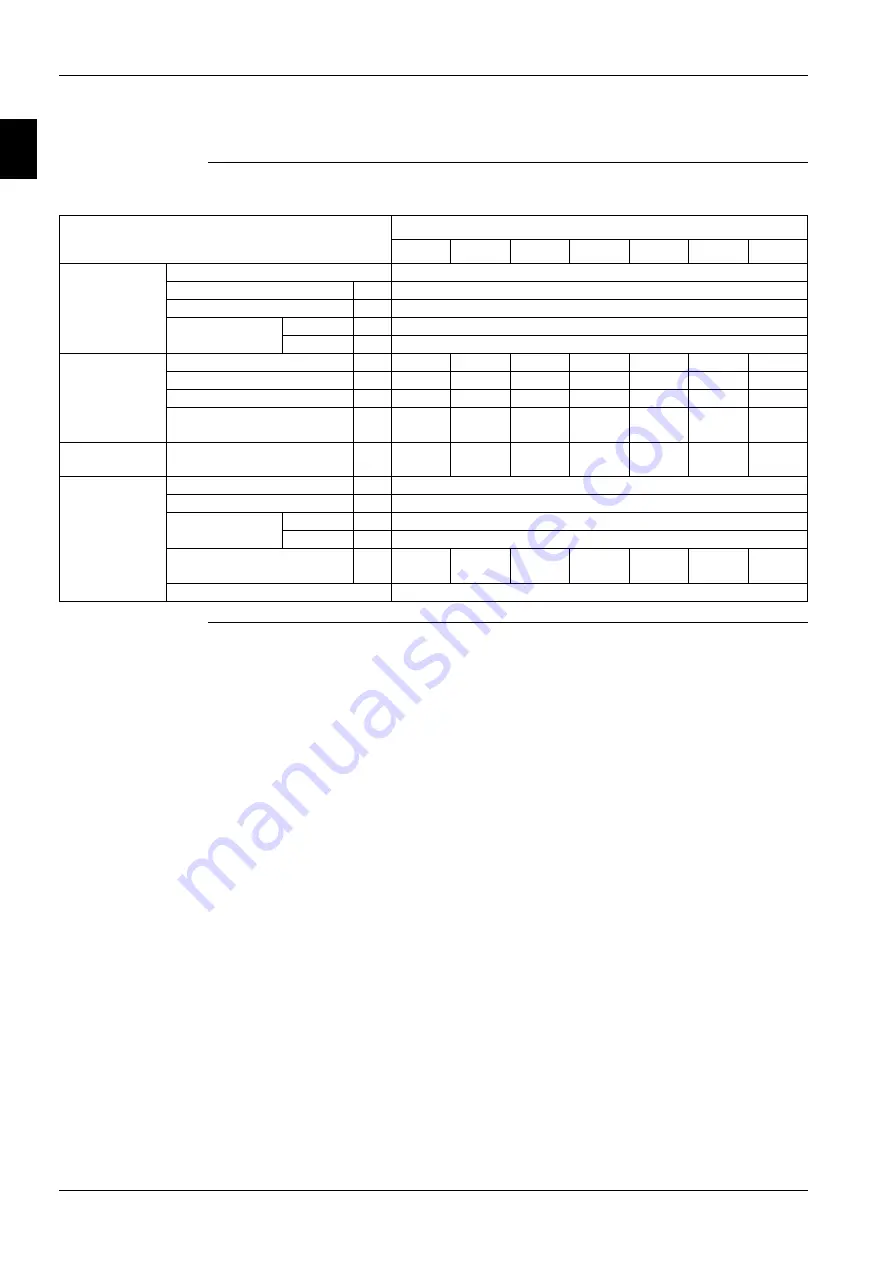

Electrical Specifications: EWAD~C-PL

Electrical

specifications

The table below contains the electrical specifications

Model

EWAD~C-PL

820

890

980

C11

C12

C13

C14

Power Supply

Phase

3

Frequency

Hz

50

Voltage

V

400

Voltage Tolerance

Minimum

%

-10%

Maximum

%

+10%

Unit

Maximum starting current

A

660.4

697.2

697.2

936.2

981.8

1041

1049

Nominal

running

current

cooling

A

384 420 461 506 551 609 665

Maximum

running

current

A

518 564 610 675 732 804 876

Maximum current for wires siz-

ing

A

570 620 671 743 805 884 964

Fans

Nominal running current in cool-

ing

A

72 72 72 80 80 88 96

Compressor

Phase

No.

3

Voltage

V

400

Voltage Tolerance

Minimum

%

-10%

Maximum

%

+10%

Maximum running current

A

223

+223

223

+269

269

+269

269

+326

326

+326

390

+326

390

+390

Starting Method

Wye - Delta type (Y -

Δ

)

Summary of Contents for EWAD620-C17C-SL

Page 2: ......

Page 8: ...ESIE10 01 1 2 Part 1 System Outline 3 1 1 5 ...

Page 111: ...ESIE10 01 General Outline Part 1 System Outline 1 105 3 1 4 5 1 36 1 Power Compressor 1 2 ...

Page 112: ...General Outline ESIE10 01 1 106 Part 1 System Outline 3 1 1 4 5 1 36 2 Power Compressor 3 ...

Page 113: ...ESIE10 01 General Outline Part 1 System Outline 1 107 3 1 4 5 1 36 3 Kit Pumps ...

Page 122: ...General Outline ESIE10 01 1 116 Part 1 System Outline 3 1 1 4 5 1 36 12 Digital Inputs Board ...

Page 123: ...ESIE10 01 General Outline Part 1 System Outline 1 117 3 1 4 5 1 36 13 Digital Outputs Board ...

Page 124: ...General Outline ESIE10 01 1 118 Part 1 System Outline 3 1 1 4 5 1 36 14 Digital Outputs Board ...

Page 131: ...ESIE10 01 General Outline Part 1 System Outline 1 125 3 1 4 5 1 36 21 EEXV Compressor 1 ...

Page 134: ...General Outline ESIE10 01 1 128 Part 1 System Outline 3 1 1 4 5 1 36 24 EEXV Compressor 2 ...

Page 137: ...ESIE10 01 General Outline Part 1 System Outline 1 131 3 1 4 5 1 36 27 EEXV Compressor 3 ...

Page 138: ...General Outline ESIE10 01 1 132 Part 1 System Outline 3 1 1 4 5 1 36 28 Pumps Control ...

Page 139: ...ESIE10 01 General Outline Part 1 System Outline 1 133 3 1 4 5 1 36 29 Terminals M1 M2 ...

Page 140: ...General Outline ESIE10 01 1 134 Part 1 System Outline 3 1 1 4 5 1 36 30 Terminals M3 ...

Page 141: ...ESIE10 01 General Outline Part 1 System Outline 1 135 3 1 4 5 1 36 31 Terminals M5 MQ ...

Page 148: ...General Outline ESIE10 01 1 142 Part 1 System Outline 3 1 1 4 5 ...

Page 150: ...ESIE10 01 2 2 Part 2 Functional Description 3 1 2 5 ...

Page 170: ...The Digital Controller ESIE10 01 2 22 Part 2 Functional Description 3 1 2 4 5 ...

Page 200: ...Functional Control ESIE10 01 2 52 Part 2 Functional Description 3 1 2 4 5 ...

Page 202: ...ESIE10 01 3 2 Part 3 Troubleshooting 3 1 3 5 ...

Page 254: ...Alarms and Events ESIE10 01 3 54 Part 3 Troubleshooting 3 1 3 4 5 ...

Page 266: ...Controller Inputs and Outputs ESIE10 01 3 66 Part 3 Troubleshooting 3 1 3 4 5 ...

Page 280: ...ESIE10 01 4 2 Part 4 Commissioning and Test Run 3 1 4 5 ...

Page 286: ...Pre Test Run Checks ESIE10 01 4 8 Part 4 Commissioning and Test Run 3 1 4 5 ...

Page 289: ...ESIE10 01 Running Data Part 4 Commissioning and Test Run 4 11 3 4 5 1 ...

Page 290: ...Running Data ESIE10 01 4 12 Part 4 Commissioning and Test Run 3 1 4 5 ...