ESIE10-01

General Outline

1–97

3

1

4

5

Note:

Water inlet and outlet are indicative. Please refer to the machine dimensional diagrams for exact

water connection of the partial recovery exchangers.

Description of the

refrigeration cycle

with partial heat

recovery

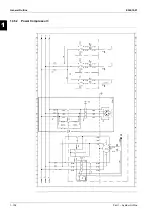

The low-temperature refrigerant gas from the evaporator is drawn by the compressor through the

electric motor, cooling it. It is subsequently compressed and during this process, the refrigerant mixes

with the oil from the oil separator.

The high-pressure oil-refrigerant mix is drawn into the high-efficiency oil separator, that separates it.

The oil depositing on the bottom of the separator through pressure difference is sent back to the

compressor while the refrigerant that has been separate from the oil is sent to the partial recovery

exchanger, where it dissipates the heat from post-overheating cooling, warming the water which

travels through the exchanger. On leaving the exchanger, the refrigerant fluid enters the condensation

bank where, by forced ventilation, it is condensed.

The condensed fluid at saturation temperature passes through the subcooling section where it loses

even more heat, increasing cycle efficiency.

The subcooled fluid then passes through the high-efficiency filter dryer. It subsequently passes

through the lamination element, which, by means of a pressure drop, starts the evaporation process.

The result at this point is a low-pressure and low-temperature liquid-gas mixture entering the

evaporator.

When the refrigerant liquid-vapour is uniformly distributed in the direct expansion evaporator tubes,

heat is exchanged with the cooling water, thus reducing the temperature, changing state until complete

evaporation, followed by superheating.

Once it has reached the superheated-vapour state, the refrigerant leaves the evaporator and is once

again taken into the compressor to repeat the cycle.

7

Condensation bank

8

Load valve

9

2-way angle valve

10

Filter dryer

11

Sight glass

12

Solenoid valve

13

Thermostatic expansion valve

14

Non-return valve

15

Electronic expansion valve

16

Water outlet temp. transducer

17

Evaporator

18

Water inlet temp. transducer

19

Low-pressure safety valve

20

Suction valve (optional)

21

Suction gas temp. transducer

22

Suction gas press. transducer

23

High-pressure pressure switch

24

Oil/delivery press. transd.

25

Delivery gas temp. transducer

26

Liquid injection valve

27

Liquid injection mesh filter

Summary of Contents for EWAD620-C17C-SS

Page 2: ......

Page 8: ...ESIE10 01 1 2 Part 1 System Outline 3 1 1 5...

Page 111: ...ESIE10 01 General Outline Part 1 System Outline 1 105 3 1 4 5 1 36 1 Power Compressor 1 2...

Page 112: ...General Outline ESIE10 01 1 106 Part 1 System Outline 3 1 1 4 5 1 36 2 Power Compressor 3...

Page 113: ...ESIE10 01 General Outline Part 1 System Outline 1 107 3 1 4 5 1 36 3 Kit Pumps...

Page 122: ...General Outline ESIE10 01 1 116 Part 1 System Outline 3 1 1 4 5 1 36 12 Digital Inputs Board...

Page 123: ...ESIE10 01 General Outline Part 1 System Outline 1 117 3 1 4 5 1 36 13 Digital Outputs Board...

Page 124: ...General Outline ESIE10 01 1 118 Part 1 System Outline 3 1 1 4 5 1 36 14 Digital Outputs Board...

Page 127: ...ESIE10 01 General Outline Part 1 System Outline 1 121 3 1 4 5 1 36 17 Extension Control Fans 4...

Page 131: ...ESIE10 01 General Outline Part 1 System Outline 1 125 3 1 4 5 1 36 21 EEXV Compressor 1...

Page 134: ...General Outline ESIE10 01 1 128 Part 1 System Outline 3 1 1 4 5 1 36 24 EEXV Compressor 2...

Page 137: ...ESIE10 01 General Outline Part 1 System Outline 1 131 3 1 4 5 1 36 27 EEXV Compressor 3...

Page 138: ...General Outline ESIE10 01 1 132 Part 1 System Outline 3 1 1 4 5 1 36 28 Pumps Control...

Page 139: ...ESIE10 01 General Outline Part 1 System Outline 1 133 3 1 4 5 1 36 29 Terminals M1 M2...

Page 140: ...General Outline ESIE10 01 1 134 Part 1 System Outline 3 1 1 4 5 1 36 30 Terminals M3...

Page 141: ...ESIE10 01 General Outline Part 1 System Outline 1 135 3 1 4 5 1 36 31 Terminals M5 MQ...

Page 148: ...General Outline ESIE10 01 1 142 Part 1 System Outline 3 1 1 4 5...

Page 150: ...ESIE10 01 2 2 Part 2 Functional Description 3 1 2 5...

Page 170: ...The Digital Controller ESIE10 01 2 22 Part 2 Functional Description 3 1 2 4 5...

Page 200: ...Functional Control ESIE10 01 2 52 Part 2 Functional Description 3 1 2 4 5...

Page 202: ...ESIE10 01 3 2 Part 3 Troubleshooting 3 1 3 5...

Page 254: ...Alarms and Events ESIE10 01 3 54 Part 3 Troubleshooting 3 1 3 4 5...

Page 266: ...Controller Inputs and Outputs ESIE10 01 3 66 Part 3 Troubleshooting 3 1 3 4 5...

Page 280: ...ESIE10 01 4 2 Part 4 Commissioning and Test Run 3 1 4 5...

Page 286: ...Pre Test Run Checks ESIE10 01 4 8 Part 4 Commissioning and Test Run 3 1 4 5...

Page 289: ...ESIE10 01 Running Data Part 4 Commissioning and Test Run 4 11 3 4 5 1...

Page 290: ...Running Data ESIE10 01 4 12 Part 4 Commissioning and Test Run 3 1 4 5...