General Outline

ESIE10-01

1–86

3

11

4

5

In case of sudden stop of the unit, follow the instructions on the Control Panel Operating Manual which

is part of the on-board documentation delivered to the end user with this manual. It is recommended

to perform installation and maintenance with other people. In case of accidental injury or unease, it is

necessary to:

Q

Keep calm.

Q

Press the alarm button if present in the installation site.

Q

Move the injured person in a warm place far from the unit and in rest position.

Q

Contact immediately emergency rescue personnel of the building or if the Health Emergency

Service.

Q

Wait without leaving the injured person alone until the rescue operators come.

Q

Give all necessary information to the rescue operators.

Warning:

Q

Before carrying out any operation on the machine, please read this instruction and operating

manual carefully. Installation and maintenance must be carried out by qualified personnel familiar

with the provisions of law and local regulations, and who has been properly trained or has

experience with this type of equipment.

Q

Avoid installing the machine in a place that could be dangerous during maintenance operations,

such as (but not only) platforms without parapets or railings, or areas not complying with the

clearance requirements.

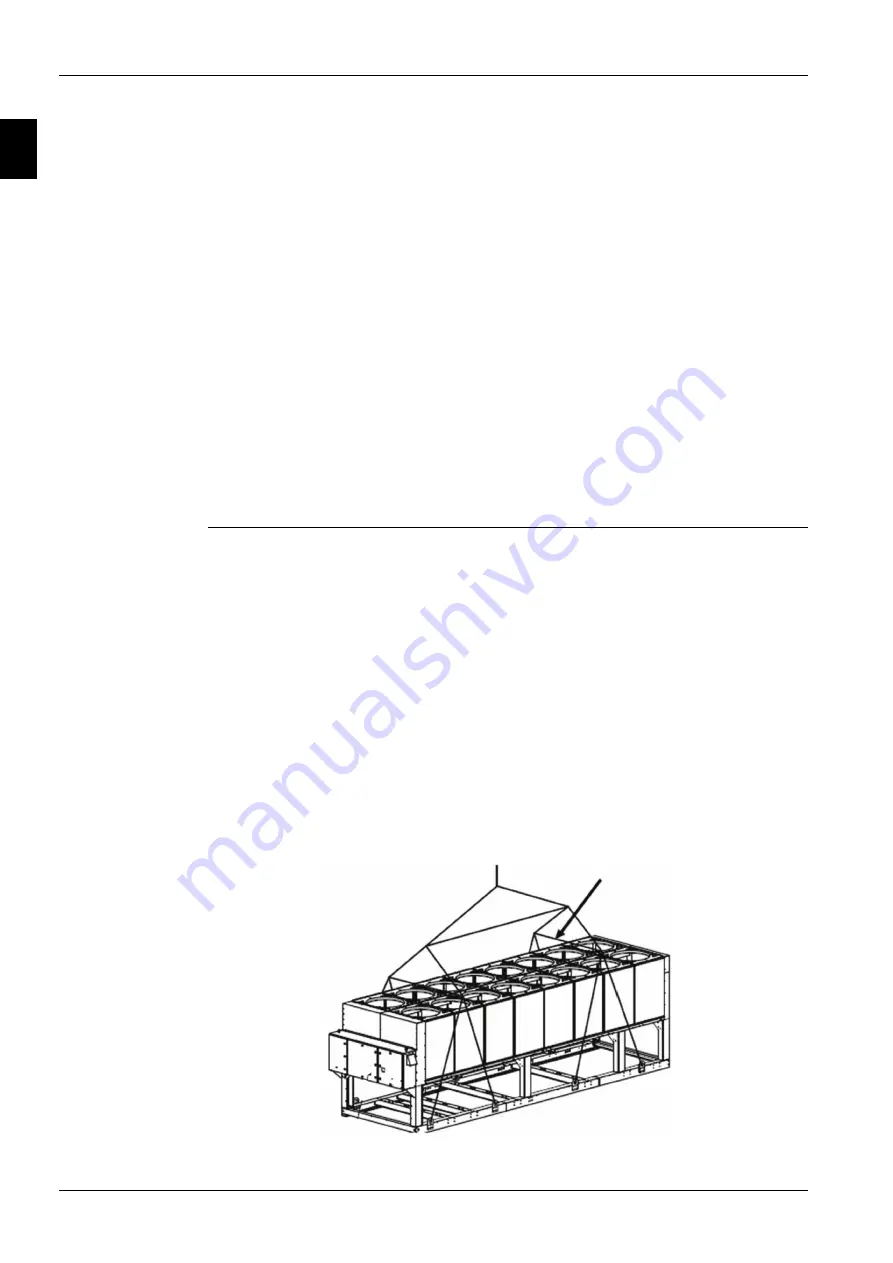

Moving and lifting

The machine must be moved and lifted by using cables, spacing bars and scales of appropriate

dimensions to the machine weight. This is stated on its identification plate. The table of weights

included in the manual should be considered as indicative only. Installation of certain accessories can

increase machine weight. Always refer to the dimensional diagrams supplied for any technical

information.

Block machine sliding on lorries to prevent damage to the panels and base frame. Avoid bumping,

jolting and impacts during unloading and/or moving the machine. Do not push or pull the machine from

any part other than the base frame. These falls could cause serious damages for which the

manufacturer will not be held liable.

All units of the series are supplied with lifting points market in yellow. Only use these points to lift the

unit, as shown in the figure.

Use spacing bars to

prevent damage to the

condensation bank.

Position these above the

fan grills at a distance of

at least 2.5 metres.

Only use the designated lifting points marked on the unit.

Lifting the unit

L1

L2

L3

L4

N.B.:

The lifting method

specified below if valid for

all EWAD-C-models

Summary of Contents for EWAD620-C17C-SS

Page 2: ......

Page 8: ...ESIE10 01 1 2 Part 1 System Outline 3 1 1 5...

Page 111: ...ESIE10 01 General Outline Part 1 System Outline 1 105 3 1 4 5 1 36 1 Power Compressor 1 2...

Page 112: ...General Outline ESIE10 01 1 106 Part 1 System Outline 3 1 1 4 5 1 36 2 Power Compressor 3...

Page 113: ...ESIE10 01 General Outline Part 1 System Outline 1 107 3 1 4 5 1 36 3 Kit Pumps...

Page 122: ...General Outline ESIE10 01 1 116 Part 1 System Outline 3 1 1 4 5 1 36 12 Digital Inputs Board...

Page 123: ...ESIE10 01 General Outline Part 1 System Outline 1 117 3 1 4 5 1 36 13 Digital Outputs Board...

Page 124: ...General Outline ESIE10 01 1 118 Part 1 System Outline 3 1 1 4 5 1 36 14 Digital Outputs Board...

Page 127: ...ESIE10 01 General Outline Part 1 System Outline 1 121 3 1 4 5 1 36 17 Extension Control Fans 4...

Page 131: ...ESIE10 01 General Outline Part 1 System Outline 1 125 3 1 4 5 1 36 21 EEXV Compressor 1...

Page 134: ...General Outline ESIE10 01 1 128 Part 1 System Outline 3 1 1 4 5 1 36 24 EEXV Compressor 2...

Page 137: ...ESIE10 01 General Outline Part 1 System Outline 1 131 3 1 4 5 1 36 27 EEXV Compressor 3...

Page 138: ...General Outline ESIE10 01 1 132 Part 1 System Outline 3 1 1 4 5 1 36 28 Pumps Control...

Page 139: ...ESIE10 01 General Outline Part 1 System Outline 1 133 3 1 4 5 1 36 29 Terminals M1 M2...

Page 140: ...General Outline ESIE10 01 1 134 Part 1 System Outline 3 1 1 4 5 1 36 30 Terminals M3...

Page 141: ...ESIE10 01 General Outline Part 1 System Outline 1 135 3 1 4 5 1 36 31 Terminals M5 MQ...

Page 148: ...General Outline ESIE10 01 1 142 Part 1 System Outline 3 1 1 4 5...

Page 150: ...ESIE10 01 2 2 Part 2 Functional Description 3 1 2 5...

Page 170: ...The Digital Controller ESIE10 01 2 22 Part 2 Functional Description 3 1 2 4 5...

Page 200: ...Functional Control ESIE10 01 2 52 Part 2 Functional Description 3 1 2 4 5...

Page 202: ...ESIE10 01 3 2 Part 3 Troubleshooting 3 1 3 5...

Page 254: ...Alarms and Events ESIE10 01 3 54 Part 3 Troubleshooting 3 1 3 4 5...

Page 266: ...Controller Inputs and Outputs ESIE10 01 3 66 Part 3 Troubleshooting 3 1 3 4 5...

Page 280: ...ESIE10 01 4 2 Part 4 Commissioning and Test Run 3 1 4 5...

Page 286: ...Pre Test Run Checks ESIE10 01 4 8 Part 4 Commissioning and Test Run 3 1 4 5...

Page 289: ...ESIE10 01 Running Data Part 4 Commissioning and Test Run 4 11 3 4 5 1...

Page 290: ...Running Data ESIE10 01 4 12 Part 4 Commissioning and Test Run 3 1 4 5...