D – 508 C – 07/02 D – EN pag. 24/36

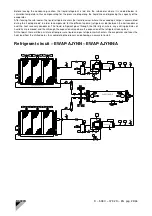

Controller

The controller is installed as standard in every unit; it can be used to modify the setpoints of the unit and to

check control parameters. A display shows the machine's operating status, programming values and

setpoints (e.g. temperatures and pressures of fluids such as water and refrigerant). This control device

maximizes the DAIKIN chiller energy efficiency and reliability. It uses sophisticated software with predictive

logic to select the most energy-efficient combination of compressor, electronic expansion valve and

condenser fan to keep stable operating conditions and maximize energy efficiency. The compressors are

automatically used on a rotation basis to ensure even operating hours. The controller protects critical

components in response to external signals received from the system field sensors measuring: motor

temperatures, refrigerant gas and oil pressures, correct phase sequence and phase failure.

Control section - main features:

•

Management of the compressor capacity slide and the electronic expansion valve in accordance with

the distributed multiprocessor logic system

•

Chillers enabled to work in partial failure condition thanks to the distributed multiprocessor logic

system

•

Full operational routines for following conditions:

-

High ambient temperature

-

High thermal load

-

High evaporator inlet water temperature (start-up)

•

Display of evaporator inlet/outlet water temperature

•

Display of both condensing and evaporating temperatures and pressures, and both suction and

discharge superheat temperatures for each circuit

•

Regulation of cooled water outlet temperature. Temperature tolerance

±

0,1°C

•

Compressors and evaporator pump hour counters

•

Display of status of safety devices

•

Equalization of the number of running sessions and working hours of the different compressors

•

Excellent management of compressors load

•

Management of cooling tower fans according to condensing pressure

•

Automatic re-start in case of power supply interruption (adjustable)

•

Soft load

•

Return temperature reset

•

AOT Reset

•

Setpoint Reset

•

Demand limit or Current limit

•

Speedtrol control (optional)

Safety - each refrigerant circuit

High pressure (pressure switch)

Low pressure (pressure switch)

Compressor overload

Condenser fan magneto-thermal protection

High discharge temperature on the compressor

Phase monitor

Star / Delta transition failure

Low delta (differential) pressure between suction and discharge

Low pressure ratio

High oil pressure drop

Low oil pressure