EWAQ+EWYQ009~0 EWAQ+EWYQ009~013ACW1

Packaged air-cooled water chillers and packaged reversible air to

water heatpumps

4PW51588-1

Operation manual

10

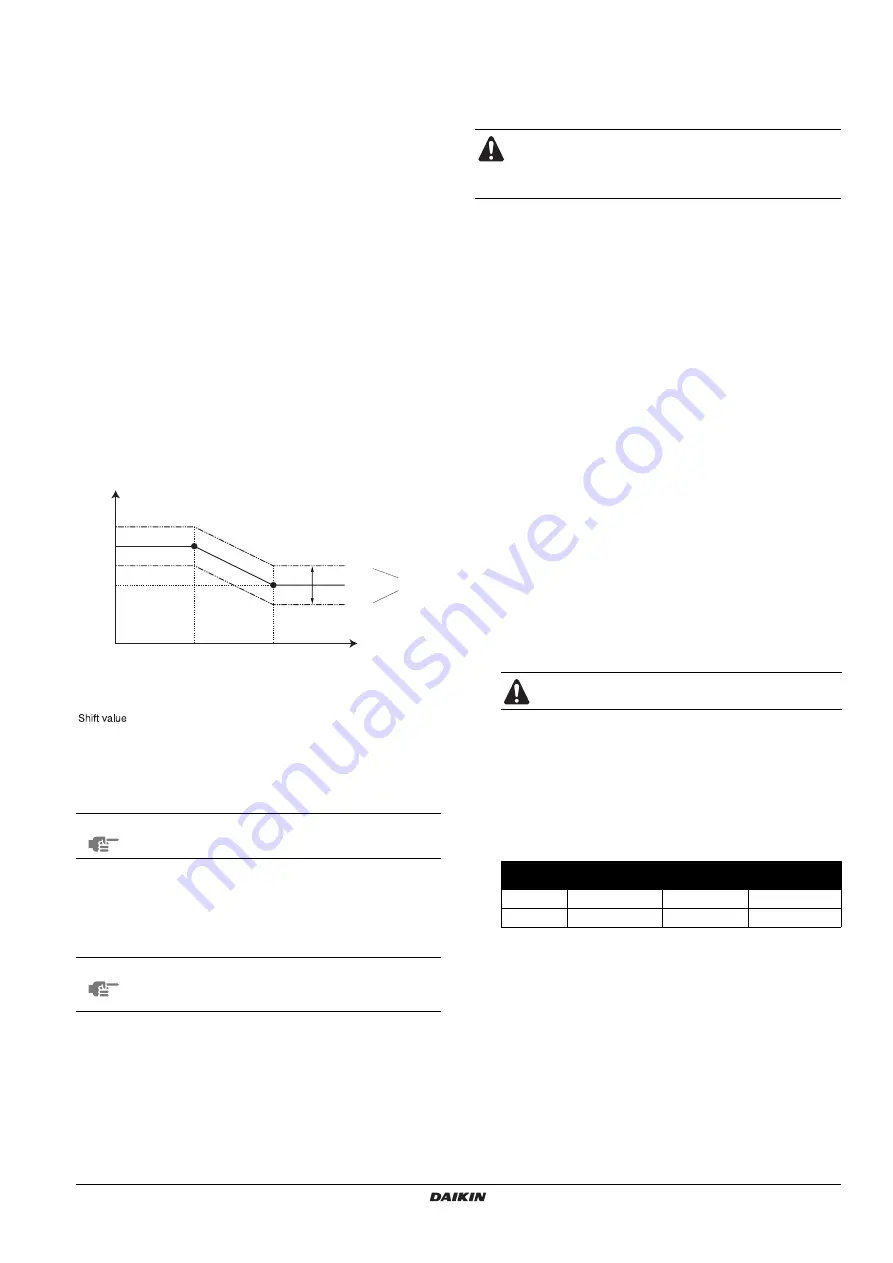

[1] Weather dependent set point (heat pump models only)

The weather dependent set point field settings define the parameters

for the weather dependent operation of the unit. When weather

dependent operation is active the water temperature is determined

automatically depending on the outdoor temperature: colder outdoor

temperatures will result in warmer water and vice versa. During

weather dependent operation, the user has the possibility to shift up

or down the target water temperature by a maximum of 5°C. See the

operation manual for more details on weather dependent operation.

■

[1-00] Low ambient temperature (Lo_A): low outdoor

temperature.

■

[1-01] High ambient temperature (Hi_A): high outdoor

temperature.

■

[1-02] Set point at low ambient temperature (Lo_Ti): the

target outgoing water temperature when the outdoor

temperature equals or drops below the low ambient

temperature (Lo_A).

Note that the Lo_Ti value should be higher than Hi_Ti, as for

colder outdoor temperatures (i.e. Lo_A) warmer water is

required.

■

[1-03] Set point at high ambient temperature (Hi_Ti): the

target outgoing water temperature when the outdoor

temperature equals or rises above the high ambient

temperature (Hi_A).

Note that the Hi_Ti value should be lower than Lo_Ti, as for

warmer outdoor temperatures (i.e. Hi_A) less warm water

suffices.

[3] Auto restart

When power returns after a power supply failure, the auto restart

function reapplies the user interface settings at the time of the power

supply failure.

Note that with the function disabled the schedule timer will not be

activated when power returns to the unit after a power supply failure.

Press the

pr

button to enable the schedule timer again.

■

[3-00] Status: defines whether the auto restart function is

turned ON (0) or OFF (1).

[9] Cooling and heating set points

The purpose of this field setting is to prevent the user from selecting

a wrong (i.e., too hot or too cold) leaving water temperature. Thereto

the heating temperature set point range and the cooling temperature

set point range available to the user can be configured.

■

[9-00] Heating set point upper limit: maximum leaving water

temperature for heating operation.

■

[9-01] Heating set point lower limit: minimum leaving water

temperature for heating operation.

■

[9-02] Cooling set point upper limit: maximum leaving water

temperature for cooling operation.

■

[9-03] Cooling set point lower limit: minimum leaving water

temperature for cooling operation.

■

[9-04] Overshoot setting: defines how much the water

temperature may rise above the setpoint before the

compressor stops. This function is only applicable in heating

mode.

[A] Quiet mode

This field setting allows to select the desired quiet mode. Two quiet

modes are available: quiet mode A and quiet mode B.

In quiet mode A, priority is given to the unit operating quietly under all

circumstances. Fan and compressor speed (and thus performance)

will be limited to a certain percentage of the speed at normal

operation. In certain cases, this might result in reduced performance.

In quiet mode B, quiet operation might be overridden when higher

performance is required. In certain cases, this might result in less

quiet operation of the unit to meet the requested performance.

■

[A-00] Quiet mode type: defines whether quiet mode A (0) or

quiet mode B (2) is selected.

■

[A-01] Parameter 01: do not change this setting. Leave it set

to its default value.

[C] Alarm output logic of EKRP1HB

■

[C-01] Defines the logic of the alarm output on the EKRP1HB

remote alarm input/output PCB.

If [C-01]=0, the alarm output will be powered when an alarm

occurs (default).

If [C-01]=1, the alarm output will not be powered when an alarm

occurs. This field setting allows for distinction between detection

of an alarm and detection of a power failure to the unit.

T

t

Target water temperature

T

A

Ambient (outdoor) temperature

= Shift value

NOTE

It is therefore recommended to leave the auto restart

function enabled.

NOTE

If the benefit kWh rate power supply is of the type that

power supply is interrupted, then always allow the auto

restart function.

Lo_Ti

Lo_A

Hi_A

T

A

T

t

+ 05

00

– 05

Hi_Ti

Shift value

In case of a floor cooling application, it is important to limit

the minimum leaving water temperature at cooling

operation (field setting of parameter [9-03]) to 16~18°C to

prevent condensation on the floor.

Do not set other values than the ones mentioned.

[C-01]

Alarm

No alarm

No power supply

to unit

0 (default)

Closed output

Open output

Open output

1

Open output

Closed output

Open output

Summary of Contents for EWAQ009ACV3

Page 15: ......

Page 16: ...4PW51588 1 Copyright Daikin ...