EWAQ+EWYQ009~0 EWAQ+EWYQ009~013ACW1

Packaged air-cooled water chillers and packaged reversible air to

water heatpumps

4PW51588-1

Operation manual

2

O

PERATING

THE

UNIT

O

PERATING

THE

DIGITAL

CONTROLLER

Operating the unit comes down to operating the digital controller.

Features and functions

The digital controller is a state of the art controller that offers full

control over your installation. It can control a cooling/heating and a

cooling only installation.

Both installations are available in multiple versions which vary in

capacity.

Basic controller functions

The basic controller functions are:

■

Turning the unit ON/OFF.

■

Operation mode change-over:

-

heating (refer to

-

cooling (refer to

-

quiet mode (refer to

■

Selection of features:

-

quiet mode (refer to

-

weather dependent control (refer to

dependent set point operation (heat pump models only)" on

page 4

■

Temperature set point adjustment (refer to

The digital controller supports a power cut off of maximum 2 hours.

When autorestart is enabled (see

allows a power supply shut down of 2 hours without user intervention

(e.g. benefit kWh rate power supply).

Clock function

The clock functions are:

■

24 hour real time clock.

■

Day of the week indicator.

Schedule timer function

The schedule timer function allows the user to schedule the

operation of the installation according to a daily or a weekly program.

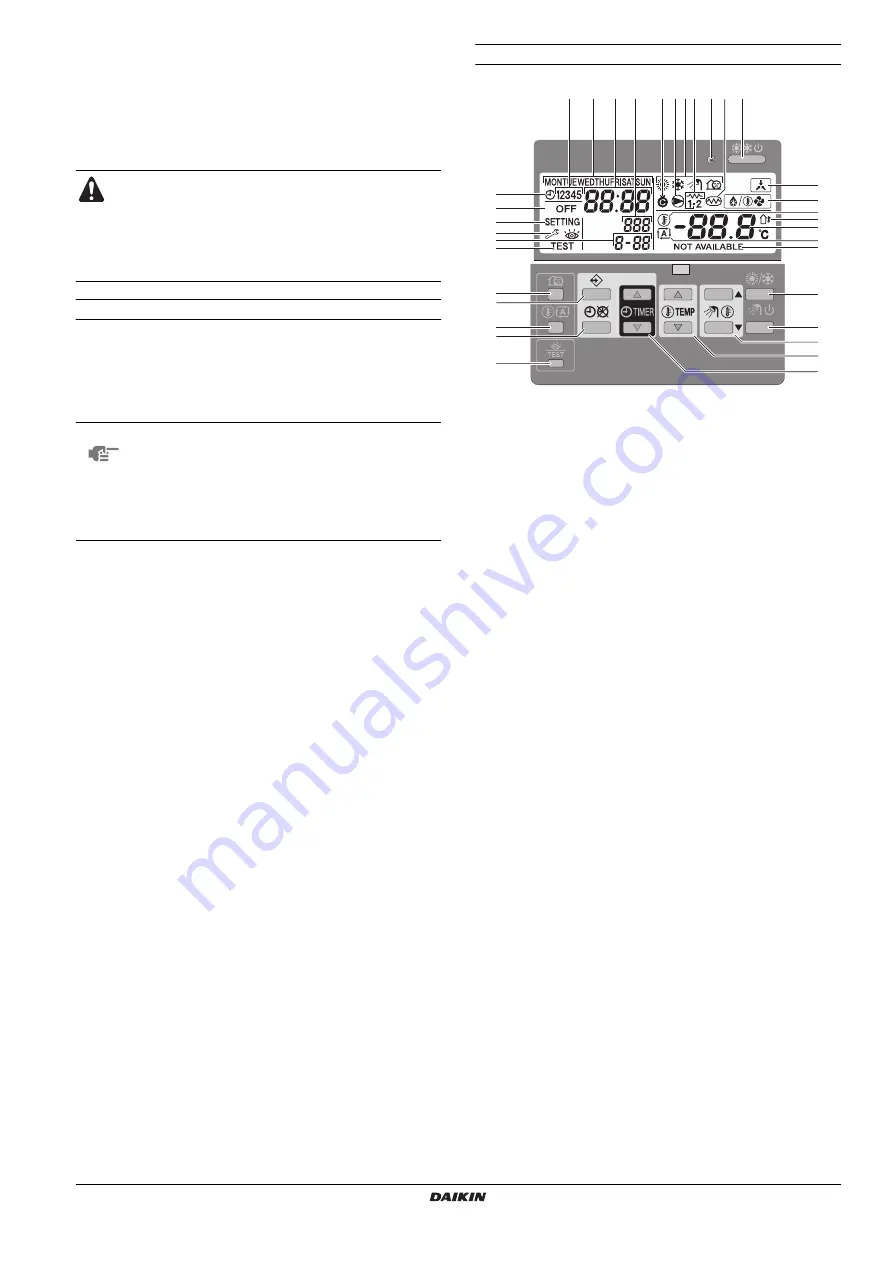

Name and function of buttons and icons

1.

COOLING/HEATING ON/OFF BUTTON

y

The ON/OFF button starts or stops the heating or cooling

function of the unit.

When the unit is connected with an external room thermostat,

this button is not operable and the icon

e

is shown.

Pressing the ON/OFF button consecutively too many times may

cause malfunction of the system (maximum 20 times per hour).

2.

OPERATION LED

0

The operation LED is lit during cooling or heating operation. The

LED blinks if a malfunction occurs. When the LED is OFF,

cooling or heating are inactive.

3.

OPERATION MODE ICONS

hcs

These icons indicate the current operation mode(s): heating (

h

),

cooling (

c

) or quiet mode (

s

). Quiet mode is a feature of the

cooling or heating operation mode. When quiet mode is

activated, the quiet mode icon and the heating or cooling mode

icon will be displayed simultaneously.

In a heating only installation, the

c

icon will never be displayed.

In a cooling only installation, the

h

icon will never be displayed.

4.

EXTERNAL CONTROL ICON

e

This icon indicates that an external room thermostat with higher

priority is controlling your installation. This external room

thermostat can start and stop the heating/cooling operation and

change the operation mode (cooling/heating).

When an external room thermostat with a higher priority is

connected, the schedule timer for cooling and heating will not

function.

5.

DAY OF THE WEEK INDICATOR

1234567

This indicator shows the current weekday.

When reading or programming the schedule timer, the indicator

shows the set day.

6.

CLOCK DISPLAY

8

The clock display shows the current time.

When reading or programming the schedule timer, the clock

display shows the action time.

7.

SCHEDULE TIMER ICON

p

This icon indicates that the schedule timer is enabled.

8.

ACTION ICONS

q

These icons indicate the programming actions for each day of

the schedule timer.

9.

OFF ICON

x

This icon indicates that the OFF action is selected when

programming the schedule timer.

Never let the digital controller get wet. This may cause an

electric shock or fire.

Never press the buttons of the digital controller with a hard,

pointed object. This may damage the digital controller.

Never inspect or service the digital controller yourself, ask

a qualified service person to do this.

NOTE

■

Descriptions in this manual that apply to a specific

installation or that depend on the installed

equipment, are marked with an asterisk (*).

■

Some functions described in this manual may not

be available or should not be available. Ask your

installer or your local dealer for more information

on permission levels.

1

17

3

5

6

24

8

13

25

26

11

19

21

14

4

7

9

12

10

22

34

27

28

23

20

33

32

31

29

30

2

16

18

15

Summary of Contents for EWAQ009ACV3

Page 15: ......

Page 16: ...4PW51588 1 Copyright Daikin ...