EWAQ016~ EWYQ016~064BAW

Packaged air-cooled water chiller

4PW70082-1C – 2013.07

Installation and operation manual

14

Procedure

1

Open the switch box cover.

2

Using the appropriate cable, connect the power supply and

communication cable(s) to the appropriate terminals as shown

on the wiring diagram and according to the figure of chapter

"4.6.6. Routing" on page 14.

3

Fix the cables with cable ties to the cable tie mountings to

ensure strain relief and to make sure that it does not come in

contact with the piping and sharp edges. Never squeeze

bundled cables.

Note: only relevant field wiring is shown in the figure of chapter

"4.6.6. Routing" on page 14.

4

Close the switch box cover following the instructions described

in "4.2.2. Opening the unit" on page 7 in reverse order.

4.6.6.

Routing

It is important to keep the power supply and the low voltage wiring

separated from each other. In order to avoid any electrical

interference the distance between both wirings should always be at

least 25 mm.

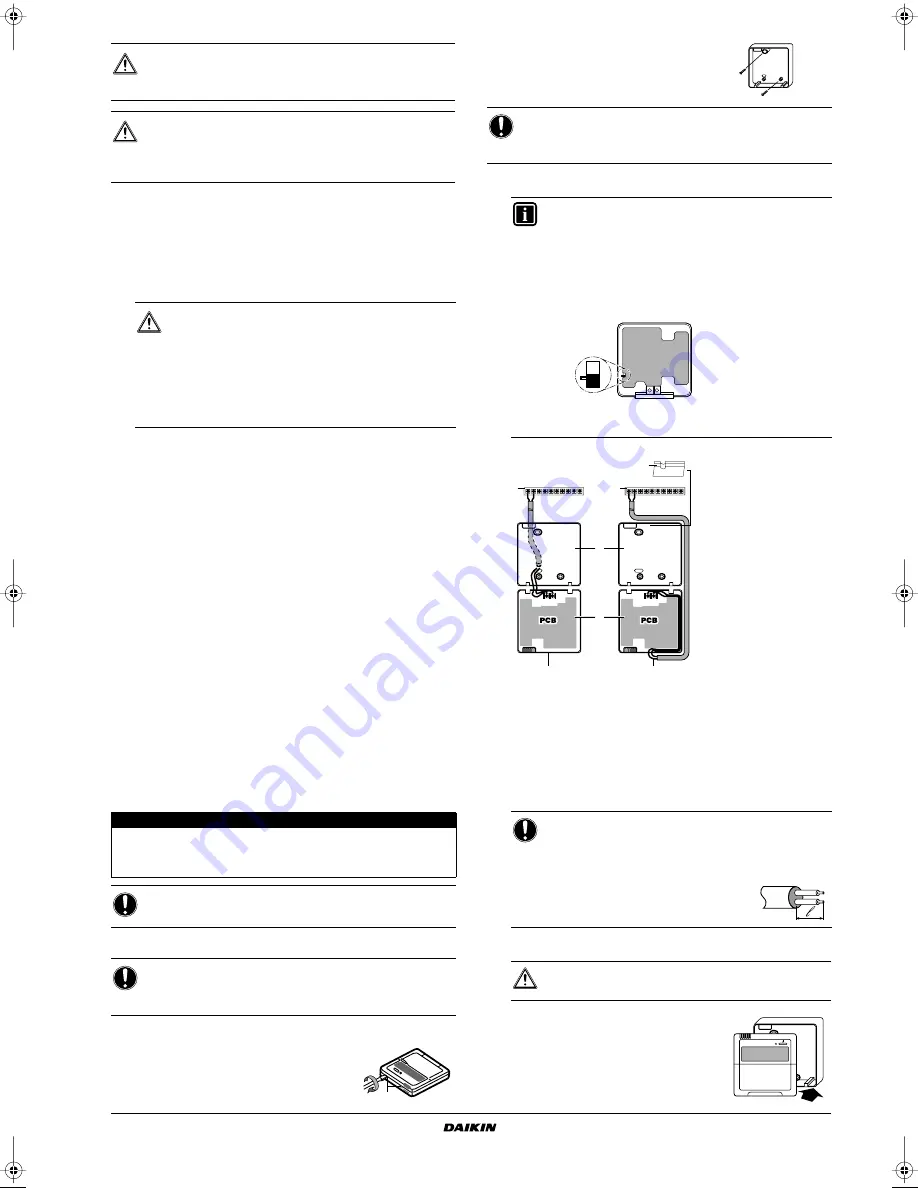

The wiring should be mounted as shown in figure 11.

PS = Power supply

LV = Low voltage

HV = High voltage

4.6.7.

Installation of the remote controller

The unit is equipped with a remote controller offering a user-friendly

way to set up, use and maintain the unit. Before operating the

controller, follow this installation procedure.

Wiring specifications

Procedure

1

Remove the front part of the remote controller.

Insert a slotted screwdriver into the slots (1)

in the rear part of the remote controller, and

remove the front part of the remote

controller.

2

Fasten the remote controller on a flat

surface.

3

Wire the unit.

1

Unit

2

Rear part of the remote controller

3

Front part of the remote controller

4

Wired from the rear

5

Wired from the top

6

Use nippers to notch the part for the wiring to pass through

Connect the terminals of the remote controller and the terminals

inside the unit (P1 to P1, P2 to P2) as shown in the figure above.

4

Reattach the upper part of the remote controller.

First begin fitting from the clips at the

bottom.

CAUTION

Select all cables and wire sizes in accordance with

relevant local and national regulations.

WARNING

After finishing the electric work, confirm that each electric

part and terminal inside the electric parts box is connected

securely.

■

To avoid receiving electric noise, be sure that the

cables are put in the correct bundle and routed in

the correct bundle tray as shown in the figure of

chapter "4.6.6. Routing" on page 14.

■

When wiring, route the cable bundles that are

outside the unit away from each other by at least

25 mm in order to avoid receiving electric noise

(external noise).

Wire specification

Value

Type

2 wire

Section

0.75~1.25 mm

2

Maximum length

500 m

NOTICE

The wiring for connection is not included.

NOTICE

The remote controller, delivered in a kit, has to be mounted

indoors.

1

NOTICE

Be careful not to distort the shape of the lower part of the

remote controller by over tightening the mounting screws.

INFORMATION

If next to the standard remote controller the optional

remote controller is installed as well:

■

Connect the electrical wires of both remote

controllers in the same way like described below.

■

Select a master and a slave remote controller by

switching the SS1 selector switch.

Only the remote controller set as master can work as

room thermostat.

NOTICE

■

When wiring, run the wiring away from the power

supply wiring in order to avoid receiving electric

noise (external noise).

■

Peel the shield for the part that

has to pass through the inside of

the remote controller case (

l

).

CAUTION

Be careful not to pinch the wiring when attaching.

S

S

M

PCB

SS1

S

Slave

M

Master

P1

P2

1

1

6

2

3

4

5

P1

P2

P2

P1

P2

P1

1

4PWEN70082-1C.book Page 14 Wednesday, September 25, 2013 7:31 AM

Summary of Contents for EWAQ016BAW

Page 47: ......