D-EIMWC01008-16_03EN - 16/35

5.3

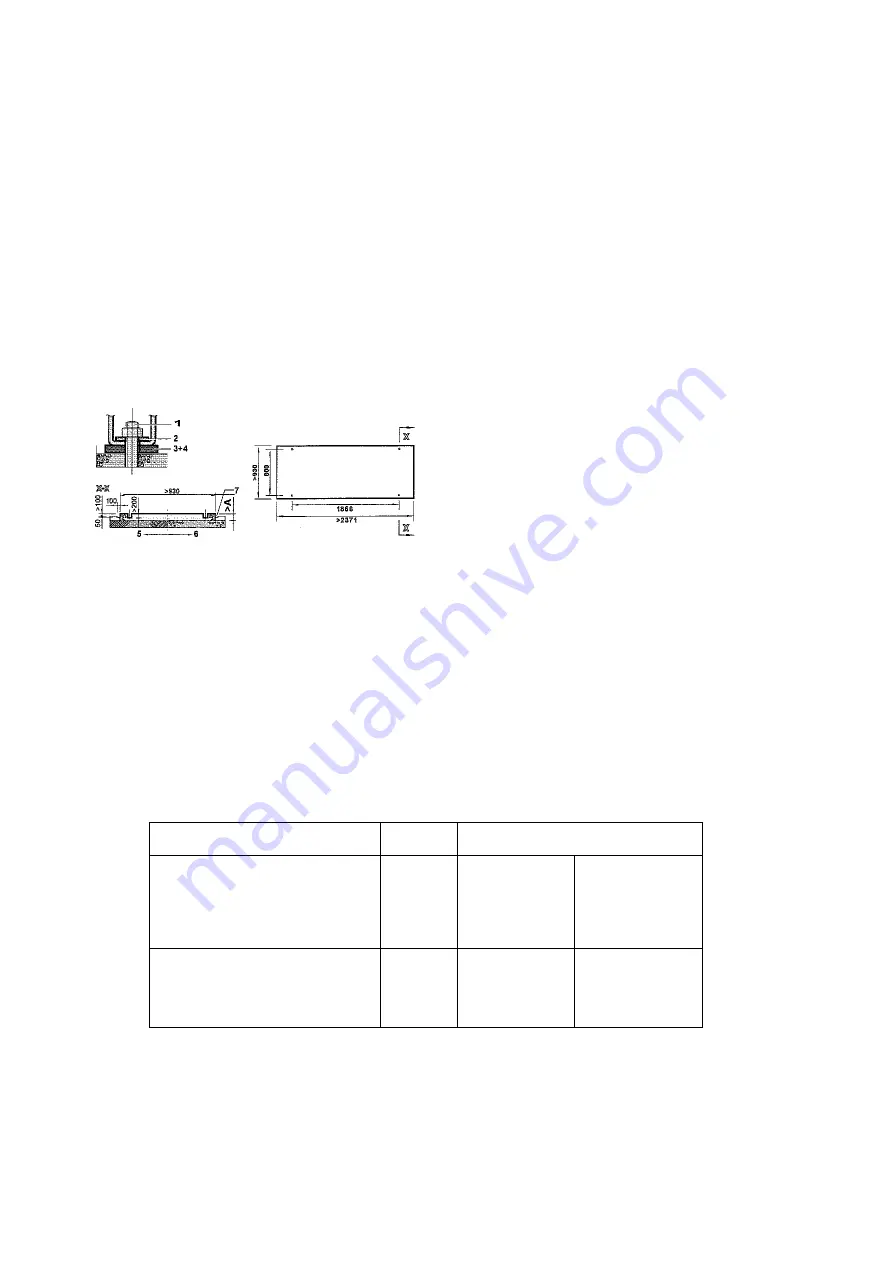

Positioning and assembly

To unpack and place the unit follow the actions listed:

1. Remove the wooden beams from the unit.

2. Install vibration mountings in case of an installation where noise and vibration might an impediment.

3. Set the unit on a solid and level foundation.

The units are designed for indoor installation and should be installed in a location that meets the following requirements:

1.

The foundation is strong enough to support the weight of the unit and the floor is flat to prevent vibration and noise generation.

2.

The space around the unit is adequate for servicing.

3.

There is no danger of fire due to leakage of inflammable gas.

4.

Select the location of the unit in such a way that the sound generated by to the unit does not disturb anyone.

5.

Ensure that water cannot cause any damage to the location in case it drips out the unit.

NOTE

Pull-down operation is restricted to one hour maximum.

It is recommended to fix the unit on a concrete base with anchor bolts.

1.

Anchor bolt

2.

Washer

3.

Rubber plate

4.

Row cork or rubber sheet

5.

Ground

6.

Concrete floor

7.

Ditch

Figure 4

– Unit Levelling

•

Fix anchor bolts into the concrete foundation. When finally fixing the unit by means of these anchor bolts, make

sure that the washers for channel DIN434, and both field supplied rubber plates and field supplied raw cork or

rubber sheets for better vibration protection, are installed as indicated.

•

The concrete foundation should approximately be 100 mm higher than the floor level for ease of plumbing work

and better drain.

Model

A

Anchor bolt

Size

Qty

EWWD120J~180J

EWLD110J~165J

EWWH090J-130J

EWLH080J-130J

EWWS120J-180J

EWLS110J-170J

300

M20x200

4

EWWD210J~280J

EWLD195J~265J

EWWH150J-200J

EWLH140J-190J

EWWS200J-270J

350

M20x200

4

5.4

Noise and Sound protection

The unit is a source of noise mainly due to rotation of compressors.

The noise level for each model size is listed in sales documentation.

If the unit is correctly installed, operated and maintained the noise emission level do not require any special protection

device to operate continuously close to the unit without any risk.