D - EIMWC01008-06_02EU - 10/182

8. INSTALLATION

8.1. Information about installation of

systems with R134a and R513A

Before machine installation and commissioning, the people

involved in this activity must have acquired the information

necessary to carry out these tasks, applying all the

information collected in this book

all the procedures reported

in the aforementioned norms and the provided requirements by

the local law.

Do not allow unauthorized and/or unskilled personnel to

access the unit.

8.2. Additional guidelines for safe use of

R134a and R513A

According to the standard EN 378-1-2016, any refrigerant

system that contains R134a or R513A, can be installed without

any restriction in open air or machinery rooms. Anyway, the

building owner or the end user shall ensure that that access is

permitted only by qualified and trained personnel, who is aware

of the general safety precautions of the building.

It is recommended to satisfy all the requirements listed in the

EN 378-3-2016 for the installation.

The refrigerant shall not be able to flow into any adjacent room,

doorway, or exhaust system in the event of a leak.

It is advised to install a refrigerant detection system which

works also during the normal operation of the refrigerant

system: in case of refrigerant leak indeed, it can activate the

alarm and all the necessary emergency procedures until the

machine shutoff.

The alarm shall also advice the authorized personnel to take

the necessary steps. The refrigerant leak detector shall be

supplied by the user because it is a key component of the

sprinkler system of the entire building.

8.3. Physical characteristics of

refrigerant R1234ze (E)

This product can be equipped with refrigerant R1234ze(E)

which has minimal impact to the environment, thanks to its low

value of Global Warming Potential (GWP).

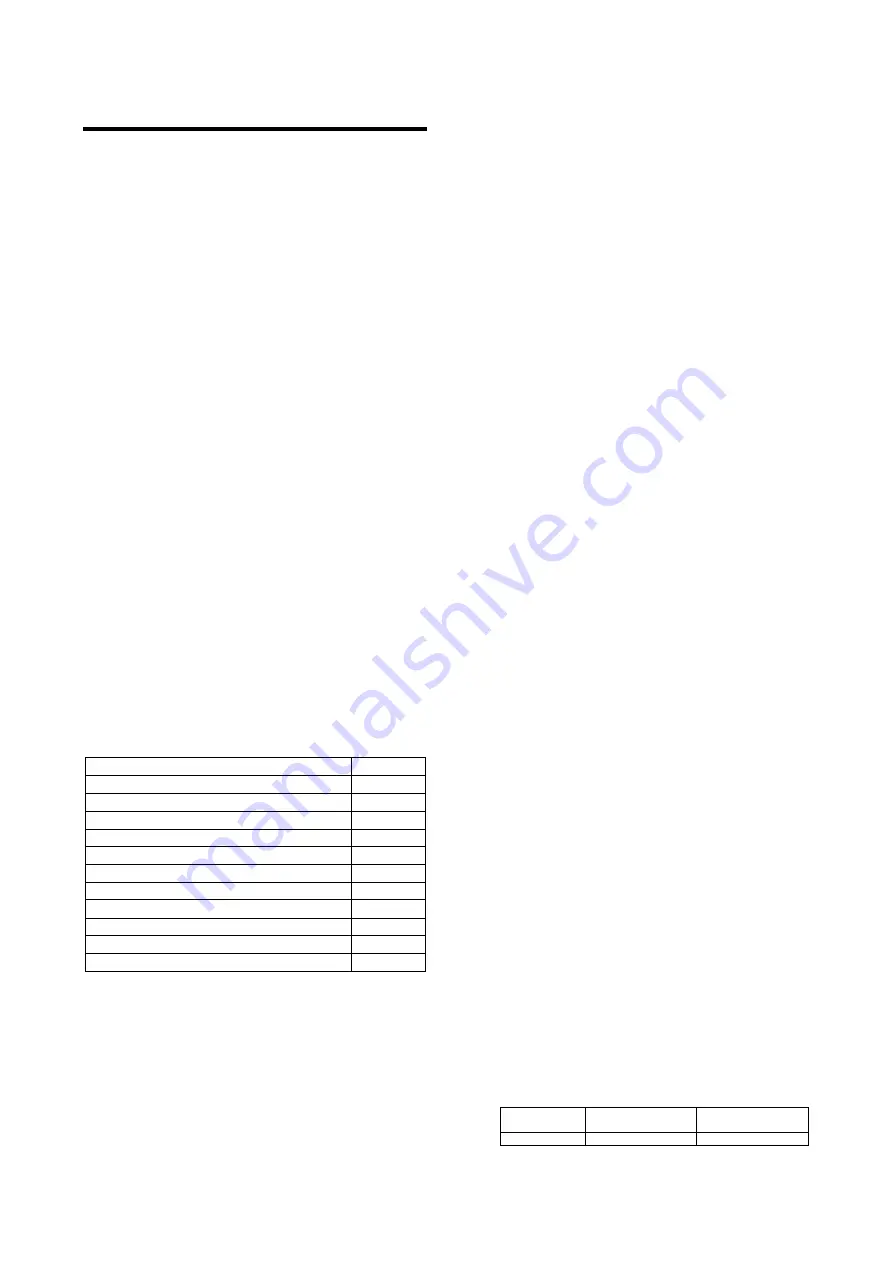

Refrigerant type

R1234ze

Safety Class

A2L

PED Fluid Group

2

Practical limit (kg/m

3

)

0.061

ATEL/ ODL (kg/m

3

)

0.28

LFL (kg/m

3

)@ 60°C

0.303

Vapour density @25°C, 101.3 kPa (kg/m

3

)

4.66

Molecular Mass

114.0

Normal Boling Point (°C)

-19

GWP (100 yr ITH)

7

GWP (ARS 100 yr ITH)

<1

Auto Ignition Temperature (°C)

368

8.4. Information about installation of

systems with R1234ze

The chillers are built in accordance with the main European

Directives (Machinery Directive, Low Voltage Directive,

Electromagnetic Compatibility Directive, Pressurized Equipment

Directive), make sure you also receive the declaration of

product conformity with the directives along with the

documentation.

Before machine installation and commissioning, the people

involved in this activity must have acquired the information

necessary to carry out these tasks, applying all the

information collected in this book. Do not allow

unauthorized and/or unskilled personnel to access the unit.

The chiller has to be installed in open air or machinery room

(location classification III).

To ensure location classification III a mechanical vent on the

secondary circuit(s) has to be installed.

Local building codes and safety standards shall be followed; in

absence of local codes and standards refer to EN 378-3:2016

as a guide. In paragraph “Additional guidelines for safe use of

R1234ze(E)” there are provided additional information that

should be added to the requirements of safety standards and

building codes.

8.5. Additional guidelines for safe use of

R1234ze(E) for equipment located in

the open air

Refrigerating systems sited in the open air shall be positioned

to avoid leaked refrigerant flowing into a building or otherwise

endangering people and property.

The refrigerant shall not be able to flow into any ventilation

fresh air opening, doorway, trap door or similar opening in the

event of a leak. Where a shelter is provided for refrigerating

equipment sited in the open air it shall have natural or forced

ventilation.

For refrigeration systems installed outside in a location where a

release of refrigerant can stagnate e.g., below ground, then the

installation shall comply with the requirements for gas detection

and ventilation of machinery rooms.

8.6. Additional guidelines for safe use of

R1234ze(E) for equipment located in

a machinery room

When a machinery room is chosen for the location of the

refrigerating equipment it shall be located in accordance with

local and national regulations. The following requirements

(according to EN 378-3:2016) can be used for the assessment.

•

A risk analysis based on the safety concept for the

refrigerating system (as determined by the manufacturer

and including the charge and safety classification of the

refrigerant used) shall be conducted to determine whether

it is necessary to place the refrigerating system in a

separate refrigeration machinery room.

•

Machinery rooms should not be used as occupied

spaces. The building owner or user shall ensure that

access is permitted only by qualified and trained

personnel doing the necessary maintenance to the

machinery room or general plant.

•

Machinery rooms shall not be used for storage with the

exception of tools, spare parts and compressor oil for the

installed equipment. Any refrigerants, or flammable or

toxic materials shall be stored as required by national

regulations.

•

Open (naked) flames shall not be permitted in machinery

rooms, except for welding, brazing or similar activity and

then only provided the refrigerant concentration is

monitored and adequate ventilation is ensured. Such

open flames shall not be left unattended.

•

A remote switching (emergency type) for stopping the

refrigerating system shall be provided outside the room

(near the door). A similar acting switch shall be located at

a suitable location inside the room.

•

All piping and ducting passing through floors, ceiling and

walls of machinery room shall be sealed.

•

Hot surfaces shall not exceed a temperature of 80 % of

the auto-ignition temperature (in °C) or 100 K less than

the auto-ignition temperature of the refrigerant, whichever

is higher.

Refrigerant

Auto ignition

temperature

Maximum surface

temperature

R1234ze

368 °C

294 °C