Installation manual

2

EWLP012~065KBW1N

Condenserless water-cooled water chillers

4PW61665-1 – 07.2010

Features

■

Voltage free contacts

-

general operation

-

alarm

-

operation compressor 1

-

operation compressor 2

■

Changeable remote inputs

Following functions can be assigned to a total of 2 digital inputs.

-

remote start/stop

-

remote cooling/heating

-

dual setpoint

O

PERATION

RANGE

M

AIN

COMPONENTS

(refer to the outlook diagram supplied

with the unit)

1

Compressor

2

Evaporator

3

Accumulator

4

Switchbox

5

Chilled water in

6

Chilled water out

7

Discharge stop valve

8

Liquid stop valve

9

Evaporator entering water temperature sensor

10

Freeze-up sensor

11

Digital display controller

12

Power supply intake

13

Ball valve (field installed)

14

Water filter (field installed)

15

Air purge valve (field installed)

16

T-joint for air purge (field installed)

17

Flowswitch (with T-joint) (field installed)

18

Main switch

S

ELECTION

OF

LOCATION

The units are designed for indoor installation and should be installed

in a location that meets the following requirements:

1

The foundation is strong enough to support the weight of the unit

and the floor is flat to prevent vibration and noise generation.

2

The space around the unit is adequate for servicing.

3

There is no danger of fire due to leakage of inflammable gas.

4

Select the location of the unit in such a way that the sound

generated by the unit does not disturb anyone.

5

Ensure that water cannot cause any damage to the location in

case it drips out of the unit.

The equipment is not intended for use in a potentially explosive

atmosphere.

I

NSPECTING

AND

HANDLING

THE

UNIT

At delivery, the unit should be checked and any damage should be

reported immediately to the carrier claims agent.

U

NPACKING

AND

PLACING

THE

UNIT

1

Cut the straps and remove the cardboard box from the unit.

2

Cut the straps and remove the cardboard boxes with waterpiping

from the pallet.

3

Remove the four screws fixing the unit to the pallet.

4

Level the unit in both directions.

5

Use four anchor bolts with M8 thread to fix the unit in concrete.

6

Remove the service front plate.

I

MPORTANT

INFORMATION

REGARDING

THE

REFRIGERANT

USED

This product is factory charged with N2.

The refrigerant system will be charged with fluorinated greenhouse

gases covered by the Kyoto Protocol. Do not vent gases into the

atmosphere.

Refrigerant type:

R407C

GWP

(1)

value:

1652.5

(1)

GWP = global warming potential

Please fill in with indelible ink,

■

the total refrigerant charge

on the fluorinated greenhouse gases label supplied with the product.

The filled out label must be adhered on the inside of the product and

in the proximity of the product charging port (e.g. on the inside of the

service cover).

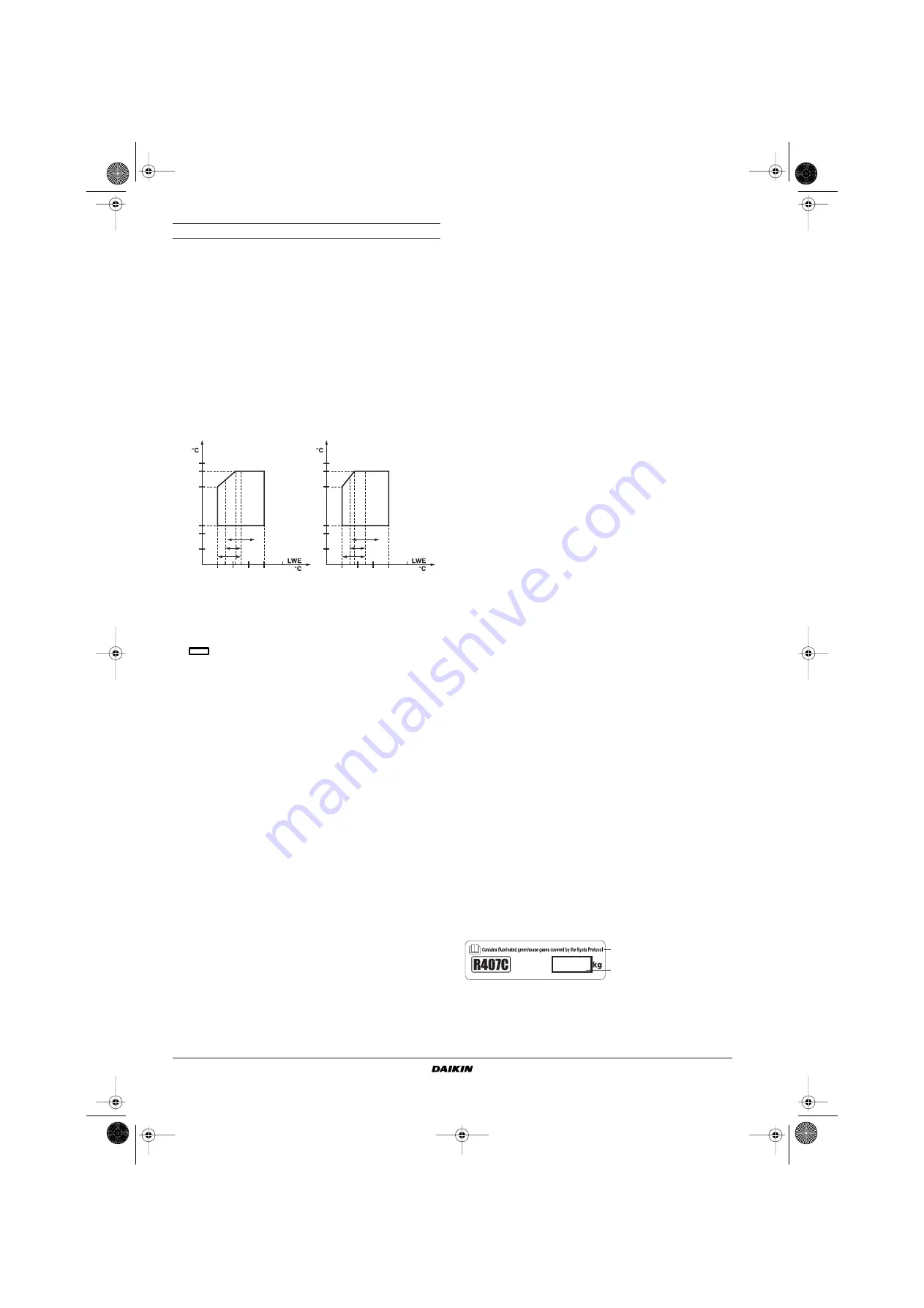

CT

Condensing temperature (bubble)

LWE

Leaving water temperature evaporator

a

Glycol

b

Water

Standard operation range

0

10

20

–10

–5

5

32

25

0

10

20

50

60

CT

ZL

ZL

ZH

ZH

ZL

ZH

1.5

1.5

1.5

25

a b

a b

a b

0

10

20

–10

–5

5

32

25

0

10

20

25

50

60

CT

ZL

ZL

ZH

ZH

ZL

ZH

-2

-2

–2

65

65

a b

a b

a b

EWLP012~030

EWLP040~065

2

1

1

total refrigerant charge

2

Contains fluorinated

greenhouse gases

covered by the Kyoto

Protocol

4PW61665-1_digital_EN.book Page 2 Friday, August 27, 2010 2:13 PM