Installation manual

4

EWLP012~065KBW1N

Condenserless water-cooled water chillers

4PW61665-1 – 07.2010

■

When connecting the flare nut, coat the flare inner surface with

ether oil or ester oil and initially tighten 3 or 4 turns by hand

before tightening firmly.

■

Check the pipe connector for gas leaks.

■

The discharge and liquid line are to be connected with flare

connections to the remote condenser piping. For use of the

correct pipe diameter see

"Technical specifications" on page 1

■

piping length: equivalent

= 50 m

maximum height = 30 m

Leak test and vacuum drying

The units were checked for leaks by the manufacturer.

After connection of the piping, a leak test must be performed and the

air in the refrigerant piping must be evacuated to a value of 4 mbars

absolute by means of a vacuum pump.

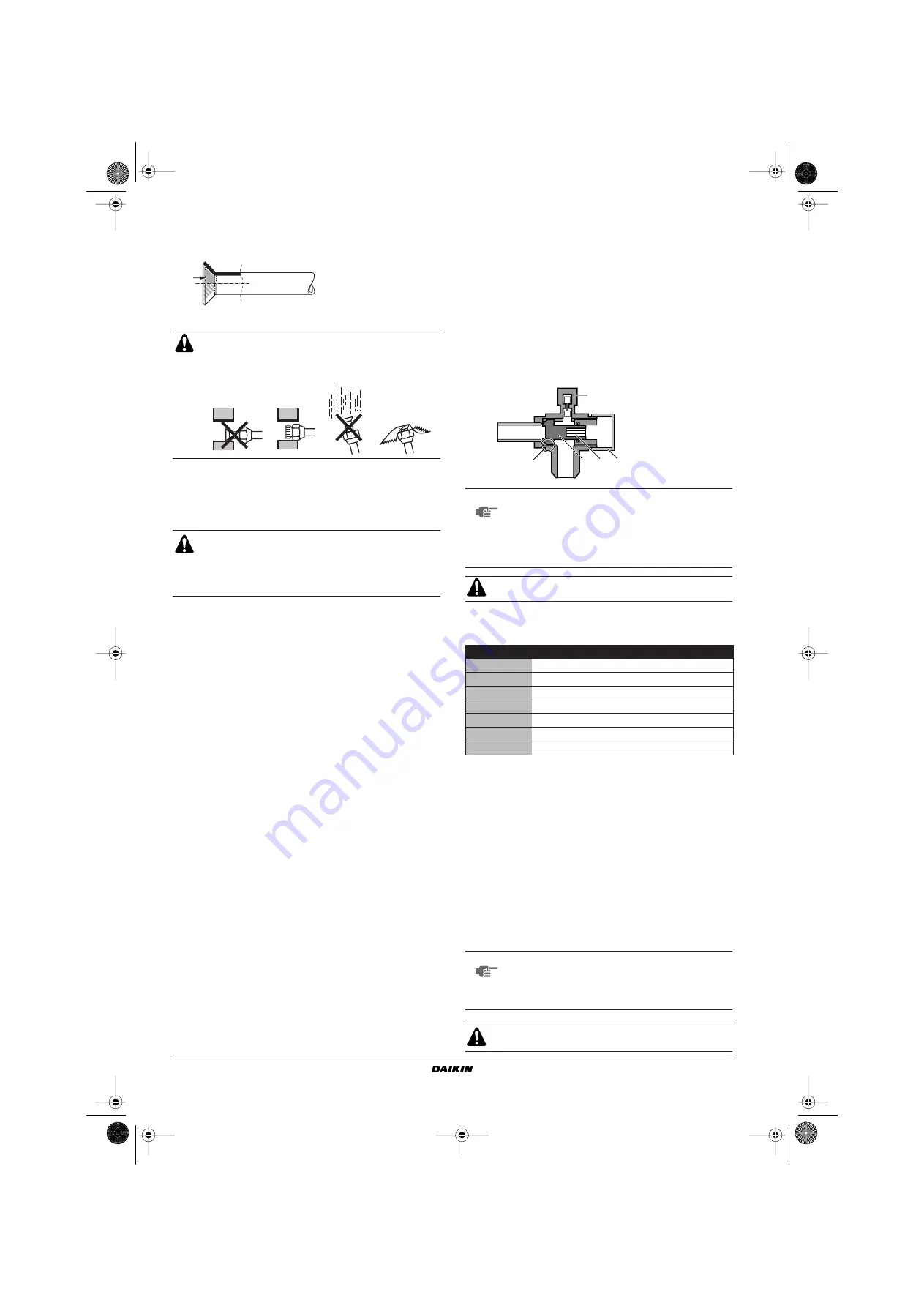

Open the discharge- and liquid stop valves.

1

to open

-

Remove the cap (1) and turn the shaft (2) counterclockwise

with hexagon socket screw keys (3) (JIS B 4648 nominal size

4 mm).

-

Turn it all the way until the shaft stops.

-

Tighten the cap firmly.

2

to close

-

Remove the cap and turn the shaft clockwise.

-

Tighten the shaft firmly until it reaches the sealed area (4) of

the body.

-

Tighten the cap firmly.

Charging the unit

First perform a rough refrigerant charge according to the table:

VRC = volume of remote condenser (l)

LLP = length of liquid pipe (m)

Next perform a fine-tuning

For fine-tuning of the refrigerant charge, the compressor must

operate.

■

If the liquid-line sightglass is showing seal after the rough

charging (due to possible different conditions), add 10%

refrigerant charge weight.

■

If the liquid-line sightglass is showing some gas-bubbles, the

rough refrigerant charge is sufficient by fine-tuning the additional

10% refrigerant charge weight.

■

If the liquid-line sightglass is showing flash gas, then charge

until one of the previous situations occur. Then fine-tune with the

additional 10% refrigerant charge weight. The unit must have the

time to stabelize which means that this charging has to be done

in a smooth way.

When inserting the refrigerant piping in the wall hole, take

care not to let dust or moisture come into the piping.

Protect the pipes with a cap or seal the pipe end

completely with tape.

Make sure the pipes are filled with N

2

during welding in

order to protect the pipes against soot.

There should be no blockage (stopvalve, solenoid valve)

between the remote condenser and the provided liquid

injection of the compressor.

NOTE

■

Use a charging hose with push rod when using

the service port (5).

■

Check for refrigerant gas leakage after tightening

the cap.

■

Make sure to keep stop valve open during

operation.

Do not purge the air with refrigerants. Use a vacuum pump

to vacuum the installation.

refrigerant charge (kg)

EWLP012

0.9+(0.(VRCx0.38)

EWLP020

1.5+(0.(VRCx0.38)

EWLP026

1.7+(0.(VRCx0.38)

EWLP030

2.0+(0.(VRCx0.38)

EWLP040

2x[1.5+(0.(VRCx0.38)]

EWLP055

2x[1.7+(0.(VRCx0.38)]

EWLP065

2x[2.0+(0.(VRCx0.38)]

NOTE

Take care for contamination of the remote condenser

in order to avoid blocking of the system. It is impossible

for Daikin to control the contamination of the "foreign"

condenser of the installer. The Daikin unit has a strict

contamination level.

Use the liquid line check valve for charging refrigerant and

make sure to charge liquid.

5

1

2

3

4

4PW61665-1_digital_EN.book Page 4 Friday, August 27, 2010 2:13 PM