Installation manual

6

EWLP012~065KBW1N

Condenserless water-cooled water chillers

4PW61665-1 – 07.2010

W

ATER

CHARGE

,

FLOW

AND

QUALITY

To assure proper operation of the unit a minimum water volume is

required in the system and the water flow through the evaporator

must be within the operation range as specified in the table below.

W

ATER

PIPING

INSULATION

The complete water circuit, inclusive all piping, must be insulated to

prevent condensation and reduction of the cooling capacity.

Protect the water piping against water freezing during winter period

(e.g. by using a glycol solution or heatertape).

R

EFRIGERANT

PIPING

INSULATION

To prevent burning injuries by accidental touching the hot (max

135°C) discharge pipe, it must be insulated thoroughly.

A minimum of insulation to protect the liquid pipe from damage is

advisable.

I

NSTALLATION

OF

THE

CONDENSER

INLET

TEMPERATURE

SENSOR

For condenser water inlet control it is possible to enlarge the provided

water sensor cable for a total length of 100 m. It gives the opportunity

to place the water sensor near to the remote watercooled condenser

in order to have a reliable condenser water inlet measurment.

Connecting sensors and power supply

Sensors can be located up to 100 meters distance away from the

controller provided that you use cables with Ø1 mm

2

min. To improve

immunity against noises we recommend using shielded cables (connect

just one end of the shielding to the earth of the electrical panel).

F

IELD

WIRING

Parts table

F1,2,3 .................... Main fuses for the unit

H3P........................ Indication lamp alarm

H4P,H5P ................ Indication lamp operation compressor circuit 1,

circuit 2

K1F,K2F ................. fancontactor

PE.......................... Main earth terminal

S7S........................ Switch for remote cooling/heating change-over

valve or dual setpoint

S9S........................ Switch for remote start/stop or dual setpoint

- - - ......................... Field wiring

Power circuit and cable requirements

1

The electrical power supply to the unit must be arranged so that

it can be switched on or off independently of the electrical supply

to other items of the plant and equipment in general.

2

A power circuit must be provided for connection of the unit. This

circuit must be protected with the required safety devices, i.e. a

circuit breaker, a slow blow fuse on each phase and an earth

leak detector. Recommended fuses are mentioned on the wiring

diagram supplied with the unit.

Connection of the water-cooled water chiller power

supply

1

Using the appropriate cable, connect the power circuit to the N,

L1, L2 and L3 terminals of the unit. (cable section 2.5~10 mm

2

)

2

Connect the earth conductor (yellow/green) to the earthing

terminal PE.

Minimum

water volume (l)

Minimum

water flow

Maximum

water flow

EWLP012

62.1

17 l/min

69 l/min

EWLP020

103

29 l/min

115 l/min

EWLP026

134

38 l/min

153 l/min

EWLP030

155

45 l/min

179 l/min

EWLP040

205

57 l/min

229 l/min

EWLP055

268

77 l/min

307 l/min

EWLP065

311

89 l/min

359 l/min

The water pressure should not exceed the maximum

working pressure of 10 bar.

NOTE

Provide adequate safeguards in the water circuit to

make sure that the water pressure will never exceed

the maximum allowable working pressure.

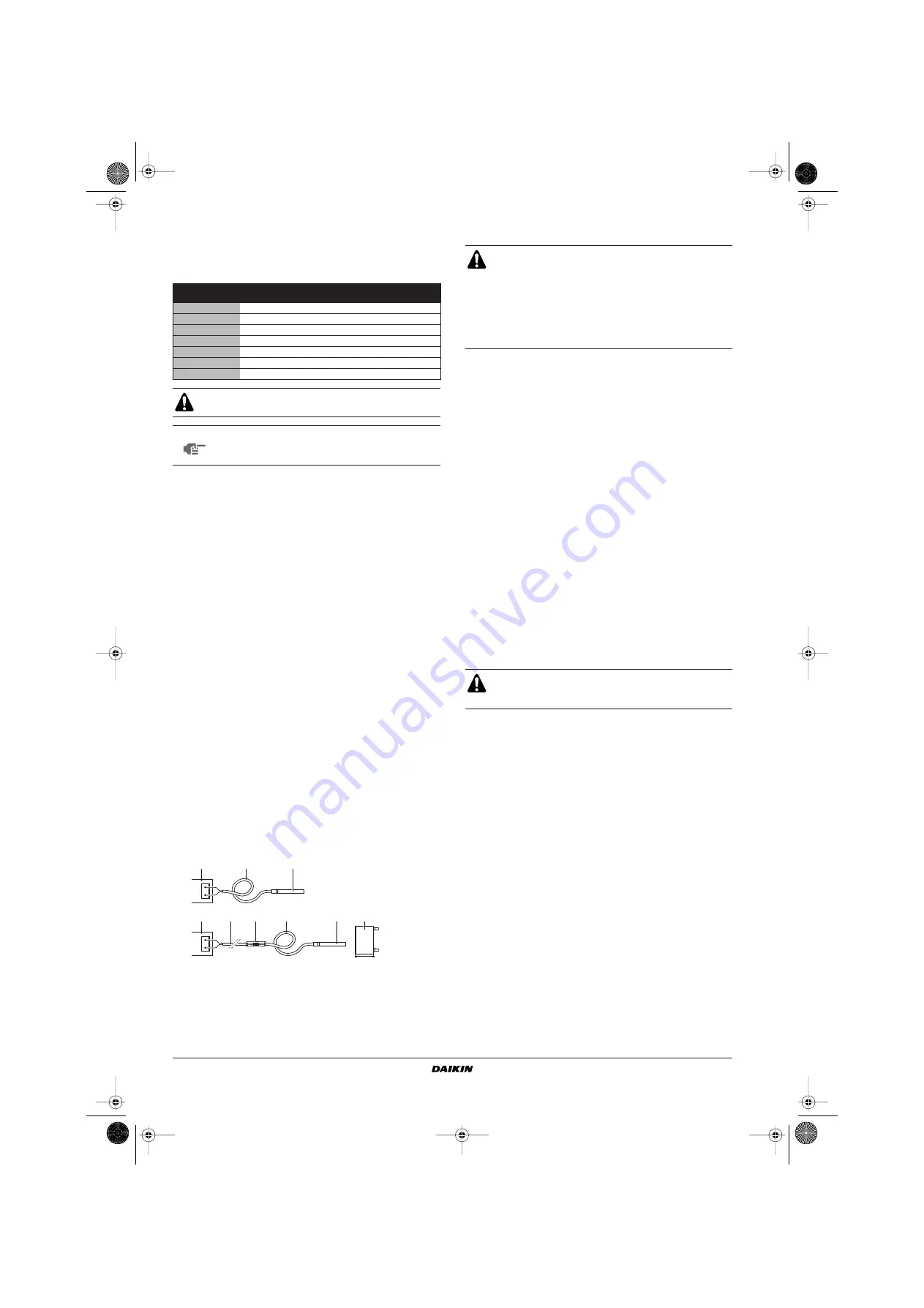

1

Switch box (with connector X62A on I/O PCB)

2

Sensor cable (length ±1 m)

3

Sensor

4

Remote watercooled condenser

5

Cable

6

Interconnection (IP67)

1

2

3

X62A

X62A

1

3

2

6

5

4

All field wiring and components must be installed by a

licensed electrician and must comply with relevant

European and national regulations.

The field wiring must be carried out in accordance with the

wiring diagram supplied with the unit and the instructions

given below.

Be sure to use a dedicated power circuit. Never use a

power supply shared by another appliance.

Switch off the main isolator switch before making any

connections (switch off the circuit breaker, remove or

switch off the fuses).

4PW61665-1_digital_EN.book Page 6 Friday, August 27, 2010 2:13 PM