D-EIMWC01008-16_03EN - 6/35

30. the machinery must be installed in structures protected against atmospheric discharge according to the applicable

laws and technical standards

31. do not bend or hit pipes containing pressurised fluids

32. it is not permitted to walk or rest other objects on the machines

33. the user is responsible for overall evaluation of the risk of fire in the place of installation (for example, calculation

of the fire load)

34. during transport, always secure the unit to the bed of the vehicle to prevent it from moving about and overturning

35. the machine must be transported according to the regulations in force taking into account the characteristics of

the fluids in the machine and the description of these on the safety data sheet

36. inappropriate transport can cause damage to the machine and even leaking of the refrigerant fluid. Before start -

up, the machine must be checked for leaks and repaired accordingly.

37. the accidental discharge of refrigerant in a closed area can cause a lack of oxygen and, therefore, the risk of

asphyxiation: install the machinery in a well ventilated environment according to EN 378 -3 and the local

regulations in force.

38. the installation must comply with the requirements of EN 378-3 and the local regulations in force; in the case of

installations indoors, good ventilation must be guaranteed and refrigerant detectors must be fitted when

necessary.

1.2

Description

The unit purchased is a Heat Pump, that is a machine designed to cool/heat the water (or a water-glycol mixture) within

certain limits which will be listed below. The unit operates based on the compression, condensation and evaporation of the

coolant gas as per the Carnot cycle, and is composed mainly of the following parts depending on the Mo de of Operation.

Cooling or Conditioning Mode:

•

Screw compressors which increase the pressure of the refrigerant gas from evaporation pressure to condensation

pressure.

•

A water-cooled condenser where the refrigerant gas condenses under high pressure and transfers heat to the

water.

•

An expansion valve which allows the pressure of condensed liquid refrigerant to be reduced from condensation

pressure to evaporation pressure.

•

A water-cooled evaporator, where the low-pressure liquid refrigerant evaporates and chills the water.

Heating Mode or Heat Pump:

•

Screw compressors compressors which increase the pressure of the refrigerant gas from evaporation pressure

to condensation pressure.

•

A condenser where the refrigerant gas condenses under high pressure and transfers heat to the water.

•

An expansion valve which allows the pressure of condensed liquid refrigerant to be reduced from condensation

pressure to evaporation pressure.

•

An evaporator, where the low-pressure liquid refrigerant evaporates and chills the water.

•

The operation of the heat exchangers can be inverted connecting the user piping to the Brazed Plate Heat

exchanger (chilled water) or to the shell&tube heat exchanger (heated water).

All standard units are fully assembled in Daikin Applied Europe factory and tested before shipping, only the condenserless

untis can not be tested.

The EWWD(H/S)-J range consists of models with a single refrigerant circuit (from 90 to 120 kW).

The machine uses three type of refrigerant fluids: R134a, R1234ze, R513A with different envelopes.

The controller is pre-wired, set up and tested at the factory. Only normal field connections such as piping, electrical

connections and pump interlocks are required, simplifying installation and increasing reliability. All safety an d operation

control systems are installed at the factory in the control panel.

The instructions in this manual are applicable to all models in this series unless otherwise specified.

1.3

Information about the refrigerants used

This product contains fluorinated greenhouse gases. Do not vent gases into the atmosphere.

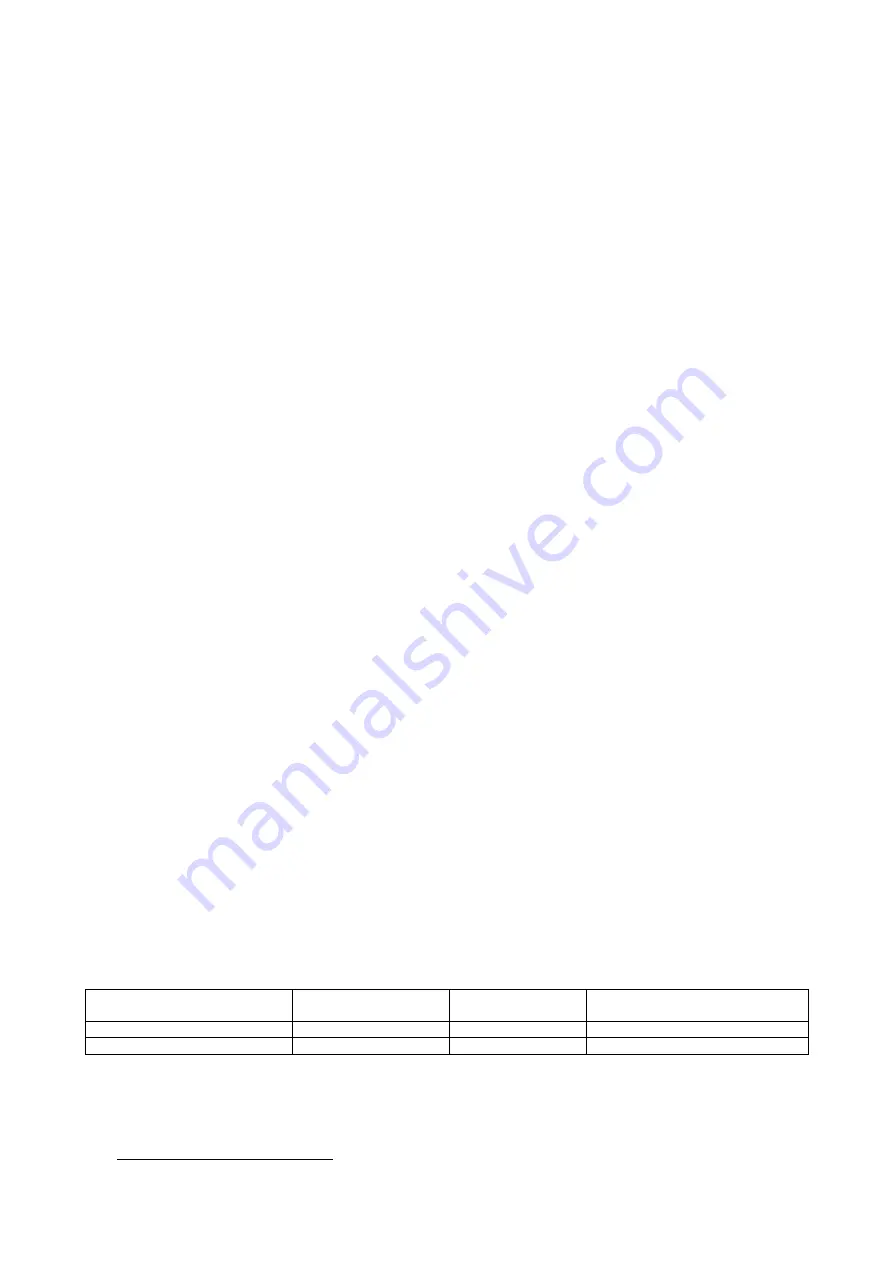

Models

EWWD J

EWLD J

EWWH J

EWLH J

EWWS J

EWLS J

Refrigerant type

R134a

R1234ze

R513A

GWP

(1)

value

1430

7

572

For the EWWD J, EWWH J and EWWS J unit versions the quantity is indicated on the unit name plate.

For the EWLD J, EWLH J and EWLS J unit versions, please fill the total refrigerant charge in with indelible ink on the

refrigerant charge label supplied with the product.

(

1

) GWP = global warming potential