D-EIMWC00908-16EN - 26/52

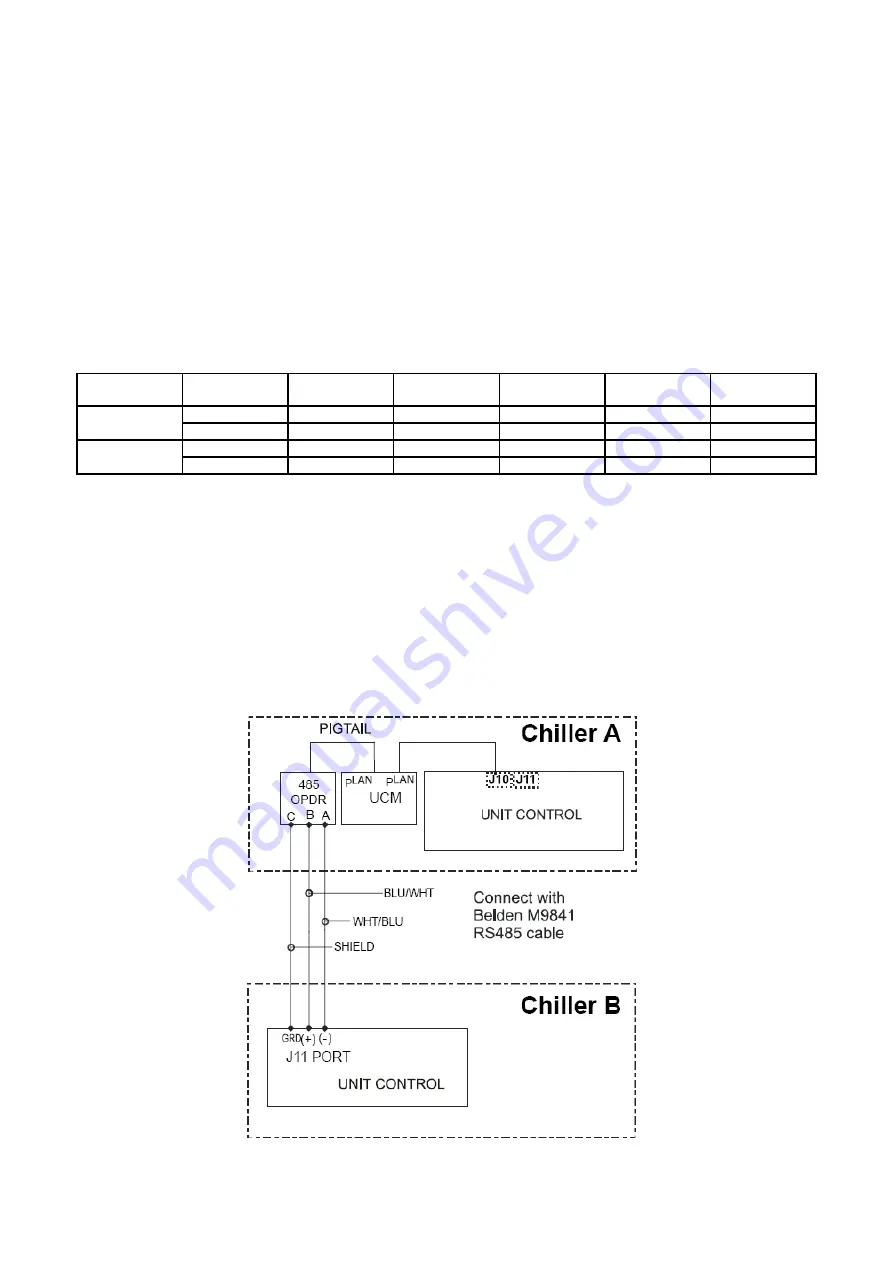

4. Connect chillers together (RS485 wiring) as shown in Figure 7. The first chiller in the connection can be designated

as Chiller A. The isolation board is attached to the DIN rail adjacent to the Chiller A unit controller. The isolation board

has a pigtail that is plugged into J10 on the controller. Most chillers will already have a universal communication

module (UCM) that connects the controller to the touchscreen already plugged onto J10. If this is the case, plug the

isolation module pigtail into the empty RJ11 pLAN port on the UCM. This is equivalent to plugging into the unit

controller directly.

Next, interconnecting wiring is needed between Chiller A and Chiller B.

Interconnection

: Belden M9841 (RS 485 Spec Cable) is wired from the 485OPDR isolation board (terminals A, B,

and C) on Chiller A to the J11 port on the unit controller of Chiller B. At J11, the shield connects to GND, the

blue/white wire to the (+) connection, and the white/blue to the (-) connection.

Note that Chiller B does not have, or need, an isolation board.

5. Verify correct nodes on each OITS Service Screen.

Table 4 - Electrical data

Chiller

(1)

Comp 1

Controller

Comp 2

Controller

Unit

Controller

Reserved

Operator

Interface (2)

Reserved

A

1

2

5

6

7

8

100000

010000

101000

011000

111000

000100

B

9

10

13

14

15

16

100100

010100

101100

011100

111100

000010

Notes:

6.

Up to four single or dual compressors can be interconnected.

7.

The Operator Interface Touch Screen (OITS) setting is not a DIP switch setting. The OITS address is selected by

selecting the ‘service’ set screen. Then, with the Technician level password active, select the ‘pLAN Comm’

button. Buttons A(7), B(15), C(23), D(31) will appear in the middle of the screen, then select the letter for the OITS

address for the chiller that it is on. Then close the screen. Note that A is the default setting from the factory.

8.

Six Binary Switches: Up is ‘On’, indicated by ‘1’. Down is ‘Off’, indicated by ‘0’

.

Figure 7

– Field wiring diagram

Summary of Contents for EWWD320

Page 16: ...D EIMWC00908 16EN 16 52 Figure 4 Evaporator pressure drop...

Page 17: ...D EIMWC00908 16EN 17 52...

Page 18: ...D EIMWC00908 16EN 18 52 Figure 5 Condenser pressure drop...

Page 34: ...D EIMWC00908 16EN 34 52 Figure 12 Compressor overview...

Page 50: ...D EIMWC00908 16EN 50 52...

Page 51: ...D EIMWC00908 16EN 51 52...