Operation manual

3

EWWP014~065KBW1N

Packaged water-cooled water chillers

4PW61660-1A – 04.2012

Function of the main components

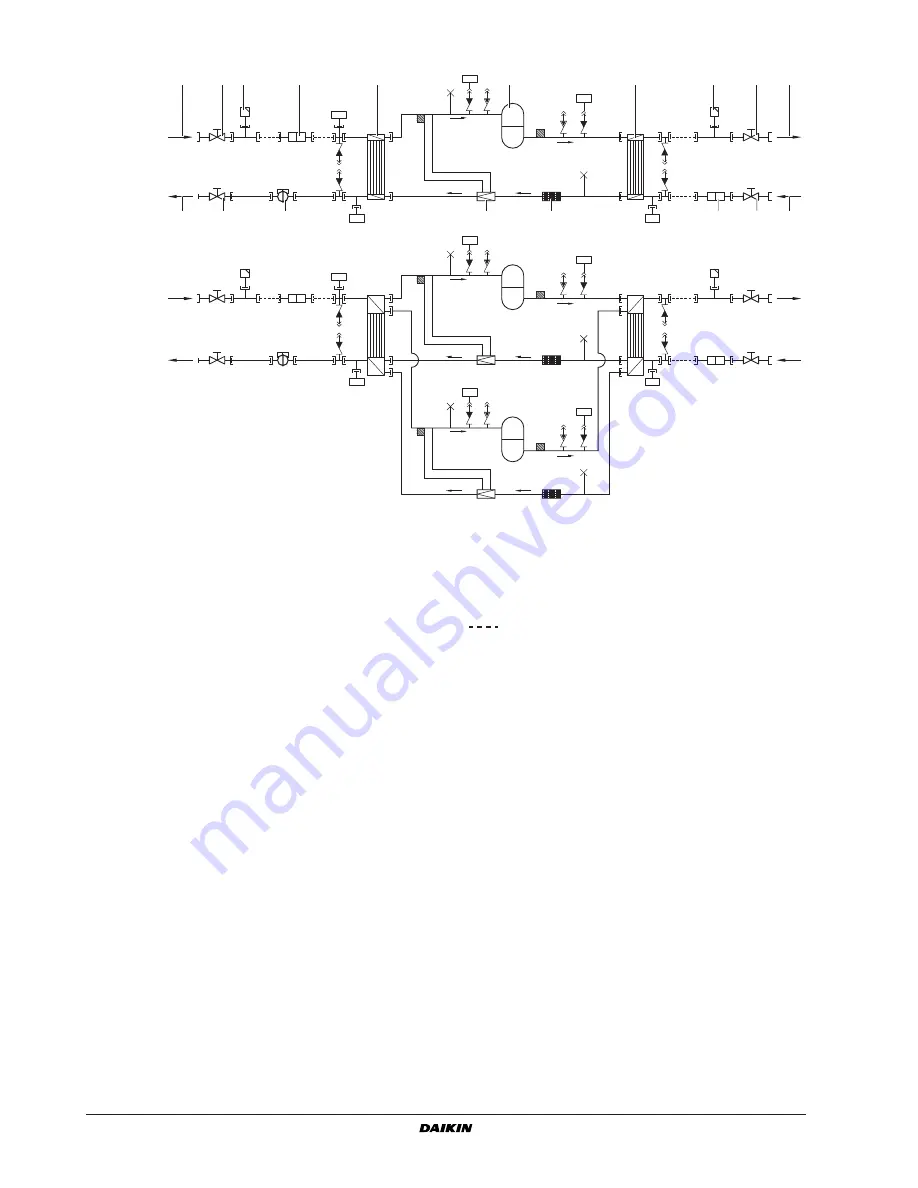

Figure -

Functional diagram

As the refrigerant circulates through the unit, changes in its state or

condition occur. These changes are caused by the following main

components:

■

Compressor

The compressor (M*C) acts as a pump and circulates the

refrigerant in the refrigeration circuit. It compresses the

refrigerant vapour coming from the evaporator to a pressure at

which it can easily be liquefied in the condenser.

■

Condenser

The function of the condenser is to change the state of the

refrigerant from gaseous to liquid. The heat gained by the gas in

the evaporator is discharged through the condenser and the

vapour condenses to liquid.

■

Filter

The filter installed behind the condenser removes small particles

from the refrigerant to prevent blockage of the tubes.

■

Expansion valve

The liquid refrigerant coming from the condenser enters the

evaporator via an expansion valve. The expansion valve brings

the liquid refrigerant to a pressure at which it can easily be

evaporated in the evaporator.

■

Evaporator

The main function of the evaporator is to take heat from the

water that flows through it. This is done by turning the liquid

refrigerant, coming from the condenser, into gaseous refrigerant.

■

Water in/outlet connections

The water inlet and outlet connection allow an easy connection

of the unit to the water circuit of the air handling unit or industrial

equipment.

Safety devices

The unit is equipped with

General safety devices

: shut down all

circuits and stop the whole unit.

■

I/O PCB (A2P) (input/output)

The I/O PCB (A2P) contains a reverse phase protector.

The reverse phase protector detects if the 3 phases of the power

supply are connected correctly. If a phase is not connected or if

2 phases are inverted, the unit can not start up.

■

Overcurrent relay

The overcurrent relay (K*S) is located in the switch box of the

unit and protects the compressor motor in case of overload,

phase failure or too low voltage. The relay is factory-set and may

not be adjusted. When activated, the overcurrent relay has to be

reset in the switch box and the controller needs to be reset

manually.

■

High-pressure switch

The high-pressure switch (S*HP) is installed on the discharge

pipe of the unit and measures the condenser pressure (pressure

at the outlet of the compressor). When the pressure is too high,

the pressure switch is activated and the circuit stops.

When activated, it resets automatically, but the controller needs

to be reset manually.

■

Low pressure switch

The low-pressure switch (S*LP) is installed on the suction pipe

of the unit and measures the evaporator pressure (pressure at

the intlet of the compressor). When the pressure is too low, the

pressure switch is activated and the circuit stops.

When activated, it resets automatically, but the controller needs

to be reset manually.

S4LP

S1HP

R3T

R5T

Q1D

HP

LP

M1C

R4T

1

2

7

6

5

3

11

9

9

10

6

7

4

S5LP

S2HP

Q2D

HP

LP

M2C

8

R3T

R4T

9

9

10

11

R5T

S4LP

S1HP

Q1D

HP

LP

M1C

EWWP012~035KB

EWWP045~065KB

1

Compressor

7

Water outlet

2

Condenser

8

Flow switch (delivered with the unit, installed in the field)

3

Filter

9

Ball valve (delivered with the unit, installed in the field)

4

Expansion valve

10

Water filter (delivered with the unit, installed in the field)

5

Evaporator

11

Air purge valve (delivered with the unit, installed in the field)

6

Water inlet

Field piping