EWWP045~06 ECB2+3MUAW

Packaged water-cooled water chillers

4PW61663-1A - 2012.04

Installation manual

3

W

ATER

QUALITY

SPECIFICATIONS

A = corrosion

B = scale

C

ONNECTING

THE

WATER

CIRCUIT

The evaporator and condenser are foreseen of GAS male pipe thread

for the water inlet and outlet (refer to the outlook diagram).

Evaporator and condenser water connections are to be made in

accordance with the outlook diagram, respecting the water in- and

outlet.

If air, moisture or dust gets in the water circuit, problems may occur.

Therefore, always take into account the following when connecting

the water circuit:

1.

Use clean pipes only.

2.

Hold the pipe end downwards when removing burrs.

3.

Cover the pipe end when inserting it through a wall so that no dust

and dirt enter.

W

ATER

CHARGE

,

FLOW

AND

QUALITY

To assure proper operation of the unit a minimum water volume is

required in the system and the water flow through the evaporator

must be within the operation range as specified in the table below.

P

IPING

INSULATION

The complete water circuit, inclusive all piping, must be insulated to

prevent condensation and reduction of the cooling capacity.

Protect the water piping against water freezing during winter period

(e.g. by using a glycol solution or heatertape).

F

IELD

WIRING

Installing the control box (ECB*MUAW)

Follow instructions in "

" (32~72 Hp) at the very end of this

manual

when installing the control box into the unit.

Parts table

F1,2,3U .................. Main fuses for the unit

H1P........................ Indication lamp alarm

H3P........................ Indication lamp operation compressor

PE .......................... Main earth terminal

S7S ........................ Remote cooling/heating change-over valve

S9S ........................ Remote start/stop switch

S10L ...................... Flowswitch

S11L ...................... Contact that closes if the pump is working

S12S ...................... Main isolator switch

- - - ......................... Field wiring

Power circuit and cable requirements

1

The electrical power supply to the unit should be arranged so

that it can be switched on or off independently of the electrical

supply to other items of the plant and equipment in general.

2

A power circuit must be provided for connection of the unit. This

circuit must be protected with the required safety devices, i.e. a

circuit breaker, a slow blow fuse on each phase and an earth

leak detector. Recommended fuses are mentioned on the wiring

diagram supplied with the unit.

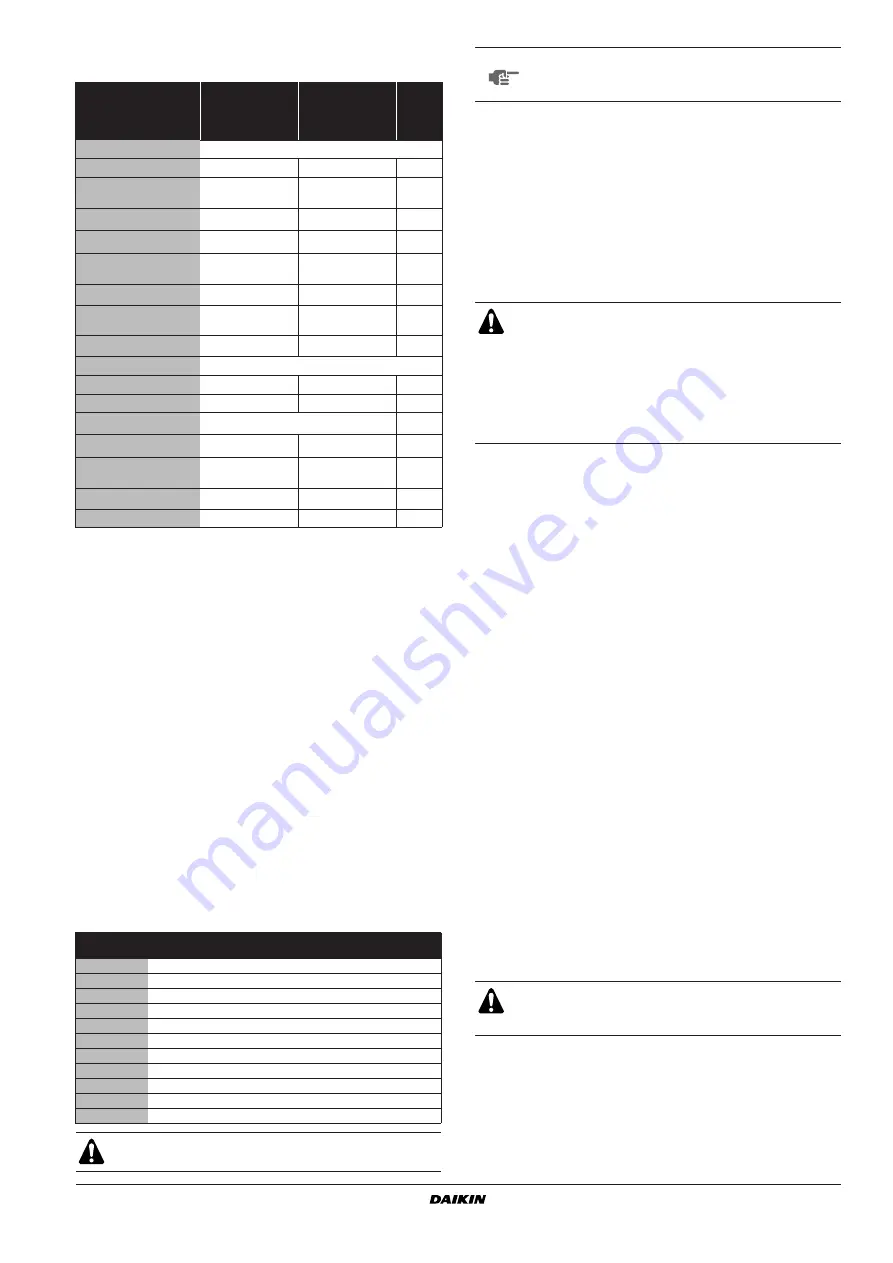

evaporator water

condenser water

circulating

water

[<20°C]

supply

water

circulating

water

[20°C~60°C]

supply

water

tendency

if out of

criteria

Items to be controlled

pH

at 25°C

6.8~8.0

6.8~8.0

7.0~8.0

7.0~8.0

A + B

Electrical

conductivity

[mS/m]

at 25°C

<40

<30

<30

<30

A + B

Chloride ion

[mg Cl

–

/l]

<50

<50

<50

<50

A

Sulfate ion

[mg SO

4

2–

/l]

<50

<50

<50

<50

A

M-alkalinity

(pH 4.8)

[mg CaCO

3

/l]

<50

<50

<50

<50

B

Total hardness

[mg CaCO

3

/l]

<70

<70

<70

<70

B

Calcium

hardness

[mg CaCO

3

/l]

<50

<50

<50

<50

B

Silica ion

[mg SiO

2

/l]

<30

<30

<30

<30

B

Items to be referred to

Iron

[mg Fe/l]

<1.0

<0.3

<1.0

<0.3

A + B

Copper

[mg Cu/l]

<1.0

<0.1

<1.0

<0.1

A

Sulfide ion

[mg S

2–

/l]

not detectable

A

Ammonium ion

[mg NH

4

+

/l]

<1.0

<0.1

<0.3

<0.1

A

Remaining

chloride

[mg Cl/l]

<0.3

<0.3

<0.25

<0.3

A

Free carbide

[mg CO

2

/l]

<4.0

<4.0

<0.4

<4.0

A

Stability index

—

—

—

—

A + B

Minimum

water volume (l)

Minimum

water flow

Maximum

water flow

32 Hp

205

202 l/min

493 l/min

36 Hp

268

232 l/min

568 l/min

40 Hp

268

262 l/min

642l/min

44 Hp

311

283 l/min

694 l/min

48 Hp

311

304 l/min

745 l/min

52 Hp

205

333 l/min

814 l/min

56 Hp

205

363 l/min

889 l/min

60 Hp

268

393 l/min

963 l/min

64 Hp

268

414 l/min

1015 l/min

68 Hp

268

435 l/min

1066 l/min

72 Hp

311

456 l/min

1118 l/min

The water pressure should not exceed the maximum

working pressure of 10 bar.

NOTE

Provide adequate safeguards in the water circuit to

make sure that the water pressure will never exceed

the maximum allowable working pressure.

All field wiring and components must be installed by a

licensed electrician and must comply with relevant

European and national regulations.

The field wiring must be carried out in accordance with the

wiring diagram supplied with the unit and the instructions

given below.

Be sure to use a dedicated power circuit. Never use a

power supply shared by another appliance.

Switch off the main isolator switch before making any

connections (switch off the circuit breaker, remove or

switch off the fuses).

Summary of Contents for EWWP045KAW1M

Page 8: ......