D

–EIMHP01201-18_06EN - 26/27

10 IMPORTANT INFORMATION REGARDING THE REFRIGERANT USED

This product contains fluorinated greenhouse gases. Do not vent gases into the atmosphere.

Refrigerant type:

R134a

GWP(1) value:

1430

(1)GWP =

global warming potential

10.1

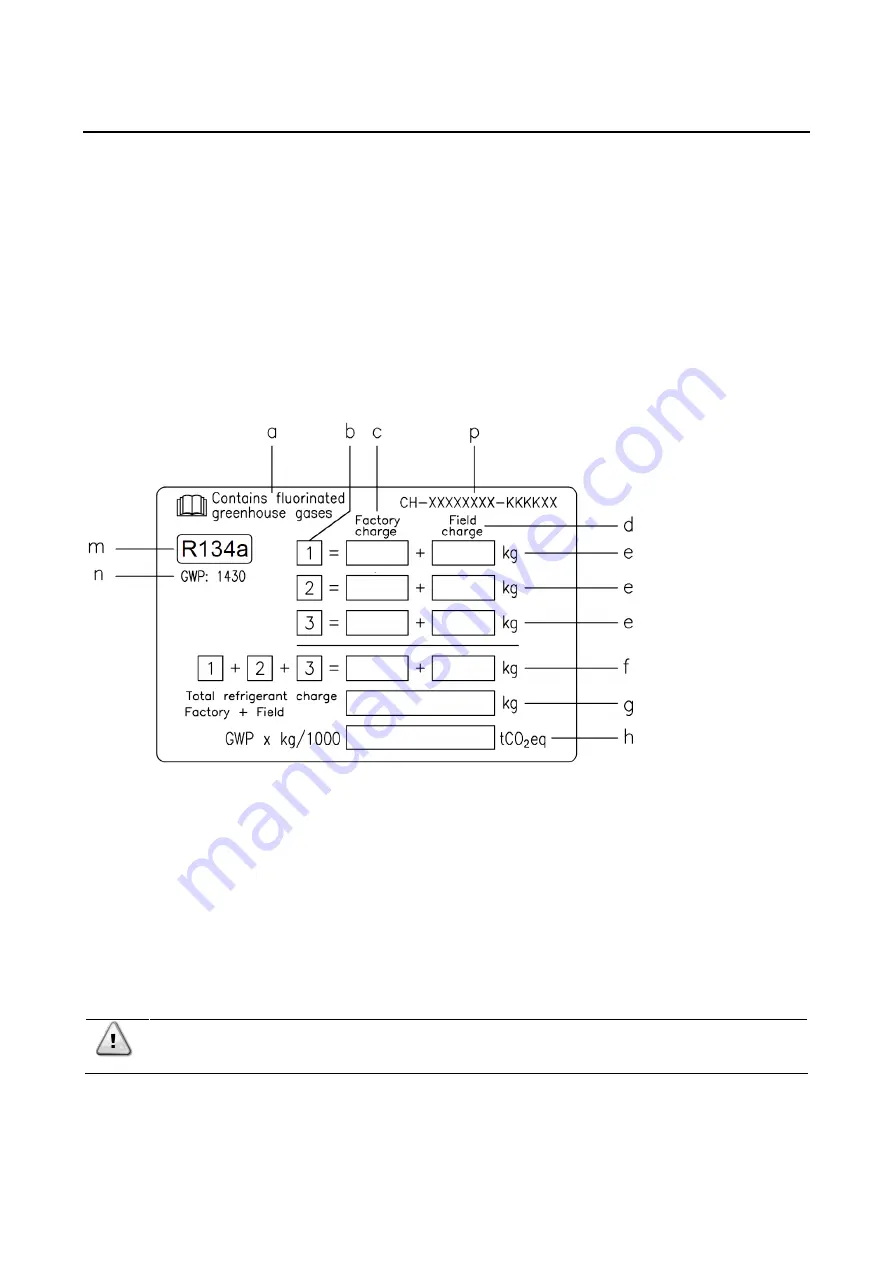

Factory And Field Charged Units Instructions

The refrigerant system will be charged with fluorinated greenhouse gases, and the factory charge(s) are recordered on the

label, shown below, which is adhered inside the electrical panel. Periodic inspections for refrigerant leaks may be required

depending on European or local legislation. Please contact your local dealer for more information.

Do not vent gases into the atmosphere.

1

Fill in with indelible ink the refrigerant charge label supplied with the product as following instructions:

-

Any refrigerant charge for each circuit (1; 2; 3) added during commissioning

-

the total refrigerant charge (1 + 2 + 3)

-

calculate the greenhouse gas emission with the following formula:

GWP value of the refrigerant x Total refrigerant charge (in kg) / 1000

a Contains fluorinated greenhouse gases

b Circuit number

c Factory charge

d Field charge

e Refrigerant charge for each circuit (according to the number of circuits)

f Total refrigerant charge

g Total refrigerant charge (F Field)

h

Greenhouse gas emission

of the total refrigerant charge expressed

as tonnes of CO2 equivalent

m Refrigerant type

n GWP = Global Warming Potential

p Unit serial number

In Europe, the emission of greenhouse gases of the total refrigerant charge in the system (expressed

in tonnes of equivalent CO

2

) is used to determine the frequency of maintenance interventions. Follow

the applicable legislation.