SiUS071735EA

Main Functions

Functions and Control

22

1.6

Schedule TIMER Operation (With Wired Remote Controller

BRC1E73)

Outline

Day settings are selected from 4 patterns:

7 Days

Weekday/Sat/Sun

Weekday/Weekend

Everyday

Up to 5 actions can be set for each day.

Details

Set the startup time and operation stop time.

ON:

Startup time, cooling and heating temperature setpoints can be configured.

OFF: Operation stop time, cooling and heating setback temperature setpoints can be

configured.

( --: Indicates that the setback function is disabled for this time period. )

__:

Indicates that the temperature setpoint and setback temperature setpoint for this time

period is not specified. The last active setpoint will be utilized.

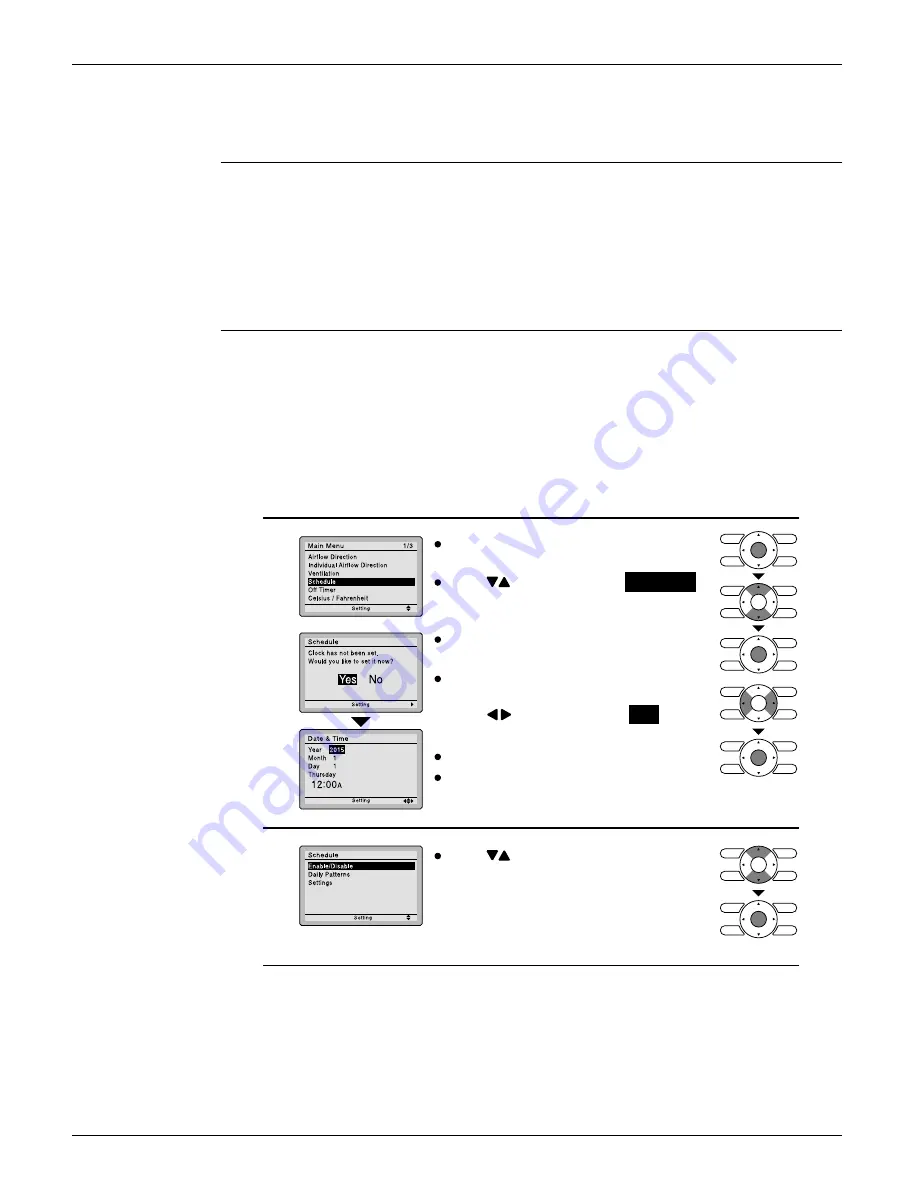

Setting the schedule

1

Press buttons to select

Schedule

.

Press

Menu/OK

button to display the

schedule screen.

The date & time screen will appear.

2

Before setting the schedule, the clock

must be set.

If the clock has not been set, a screen

like the one on the left will appear.

Press buttons to select

Yes

and

press

Menu/OK

button.

Set the current year, month, day, and

time.

Press buttons to select the desired

function on the schedule screen and

press

Menu/OK

button.

(R24369)

Press

Menu/OK

button to

display the main menu screen.

Summary of Contents for FDMQ-R Series

Page 12: ...SiUS071735EA 1 List of Functions Part 1 List of Functions 1 Functions 2...

Page 14: ...SiUS071735EA 3 Specifications Part 2 Specifications 1 Specifications 4...

Page 120: ...Check SiUS071735EA 109 Service Diagnosis 15 18 24 class R25105 1 2 3 4 Multimeter...

Page 122: ...Check SiUS071735EA 111 Service Diagnosis 15 18 24 class R20704 W V U DC_P1 DC_N1...

Page 140: ...Piping Diagrams SiUS071735EA 129 Appendix RX24RMVJU A 3D092249A...