1-15

English

7

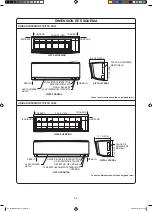

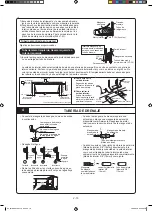

PUMP DOWN OPERATION

In order to protect the environment, be sure to pump down when relocating or disposing of the unit.

1) Remove the valve cap from liquid stop valve and gas stop valve.

2) Carry out forced cooling operation.

3) After five to ten minutes, close the liquid stop valve with a hexagonal wrench.

4) After two to three minutes, close the gas stop valve and stop forced cooling operation.

5) Attach the valve cap once procedures are complete.

Forced cooling operation

Using the indoor unit ON/OFF switch

Press the indoor unit ON/OFF switch for at least 5 seconds. (The operation will start.)

• Forced cooling operation will stop automatically after around 15 minutes.

To stop the operation, press the indoor unit ON/OFF switch.

After closing the liquid stop valve, close the gas stop valve within 3 minutes, then stop the forced cooling operation.

CAUTION

To pump down

DANGER: RISK OF EXPLOSION

Pump down - Refrigerant leakage

. If you want to pump down the system, and there is a leakage in the refrigerant circuit:

•

Do NOT use the unit

ʼ

s automatic pump down function, with which you can collect all refrigerant from the system into the

outdoor unit. Possible consequence: Self-combustion and explosion of the compressor because of air going into the

operating compressor.

•

Use a separate recovery system so that the unit

ʼ

s compressor does NOT have to operate.

NOTICE

During pump down operation, stop the compressor before removing the refrigerant piping. If the compressor is still running

and the stop valve is open during pump down, air will be sucked into the system. Compressor breakdown or damage to the

system can result due to abnormal pressure in the refrigerant cycle.

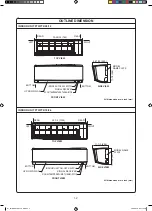

Hexagonal

wrench

Close

Valve lid

Service port

Gas stop valve

Liquid stop valve

8

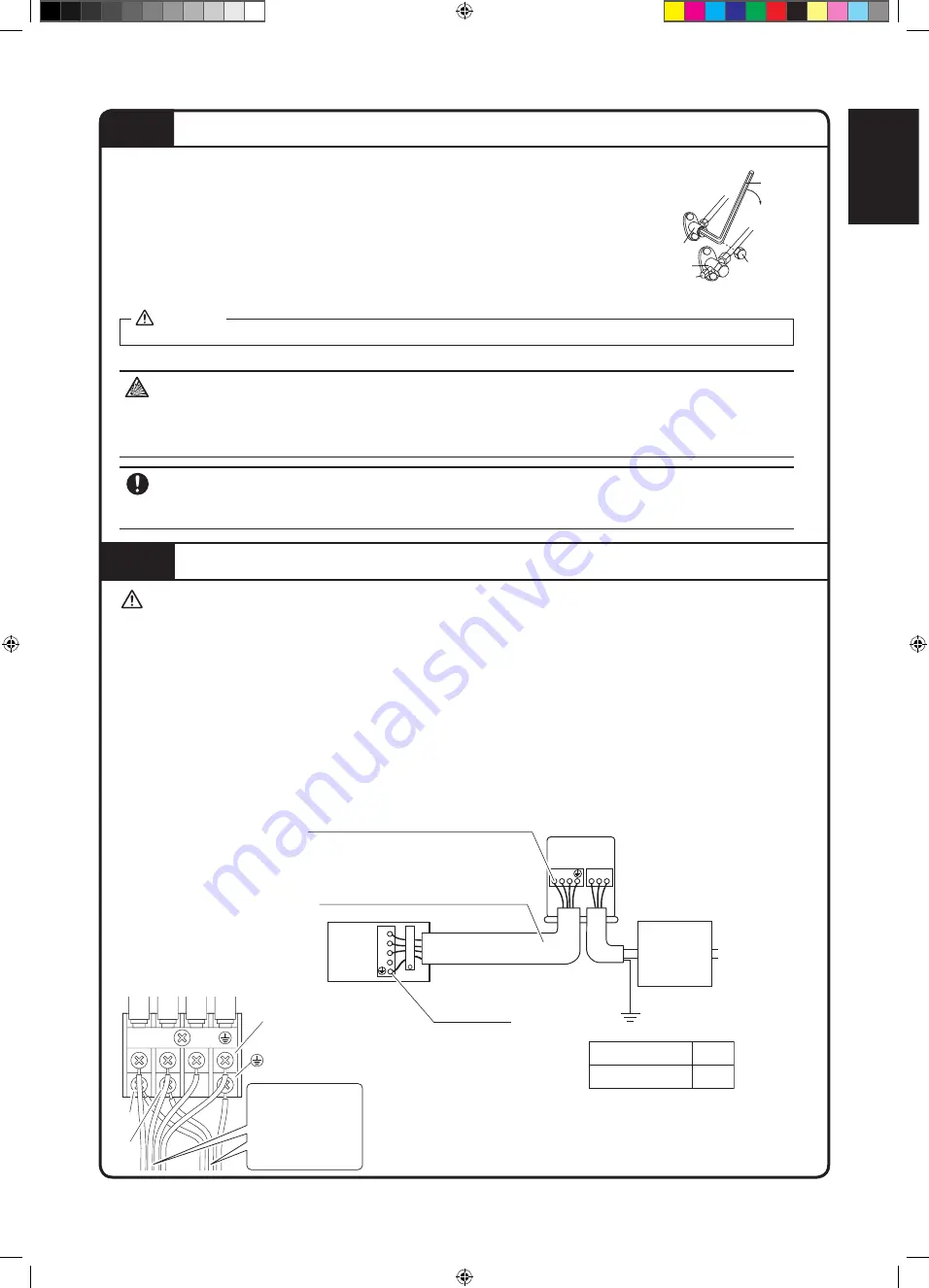

WIRING

WARNING

• Do not use tapped wires, extension cords, or starburst connections, as they may cause overheating, electric shock,

or fire.

• Do not use locally purchased electrical parts inside the product. (Do not branch the power for the drain pump, etc.,

from the terminal block.) Doing so may cause electric shock or fire.

• Be sure to install a ground fault circuit interrupter. (One that can handle higher harmonics.)

(This unit uses an inverter. Therefore, a ground fault circuit interrupter capable of handling higher harmonics must

be used in order to prevent the ground fault circuit interrupter malfunctioning.)

• Use an all-pole disconnection type circuit breaker with at least 3mm (1/8 inch) between the contact point gaps.

• When carrying out wiring, take care not to pull at the conduit.

• Do not connect the power wire to the indoor unit. Doing so may cause electric shock or fire.

• Do not turn on the circuit breaker until all work is completed.

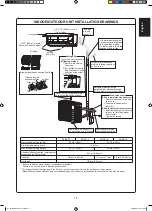

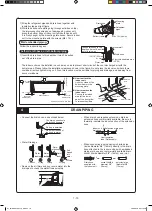

1) Strip the insulation from the wire 3/4" (20mm).

2) Connect the inter-unit wires between the indoor and outdoor units so that the terminal numbers match. Tighten

the terminal screws securely. It is recommended that a flathead screwdriver be used to tighten the screws.

The screws are packed with the terminal block.

3

1

2

1

2

3

1 2 3

L1 L2 GR

Firmly

fi

x the wires with the terminal screws.

Safety devices in

accordance with

local and national

codes, i.e. a

circuit breaker

Power supply

60Hz 208-230V

RX/RK 09/12

15A

20A

RX/RK 18/24

Firmly

fi

x the

wires with the

terminal screws.

Note: Take care to ensure that all wiring

between indoor unit and outdoor unit

has a consistent connection. Any splices

can cause communication errors.

Indoor

unit

Ground

Power supply

terminal block

L1

L2

Shape wires so

that the service

lid and stop valve

cover fit securely.

Outdoor

unit

Recommend using AWG14, stranded

and insulated wire for connections

between indoor and outdoor units.

Local code always supersedes

recommendation.

01_IM-BMS-FTX&FTK_EN.indb 15

01_IM-BMS-FTX&FTK_EN.indb 15

2/28/2020 6:27:17 PM

2/28/2020 6:27:17 PM