SIE-86

For RK25J, RK35J, RX25J, RX35J

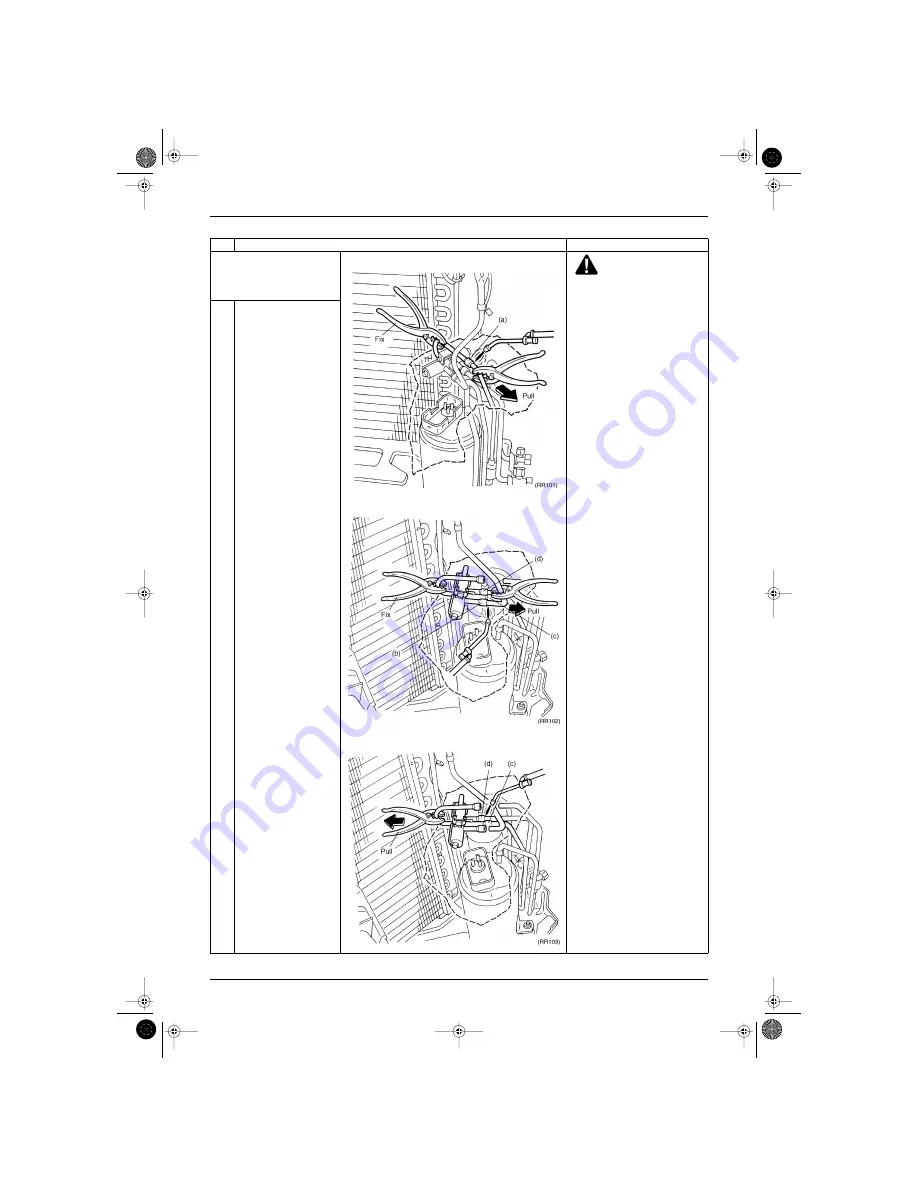

Removal Procedure

117

Begin your work after

recognizing complete empty

of refrigerant in the

refrigerant circuit.

Caution

Be careful about four-way valve,

pipes and so on , which were

heated up by a gas brazing

machine, so as not to get burnt

on your hands.

Cautions at the restoration.

1. Restore the piping by non-

oxidation brazing. Braze it

quickly unless nitrogen gas can

be used.

2. It is required to prevent the

carbonization of the oil inside the

four-way valve and the

deterioration of the gaskets

affected by heat. For the sake of

this, rap the four-way valve with

wet cloth and make up water so

that the cloth will not be dried

and avoid excessive heating.(it

keeps below 120 degree C).

Be careful so as not to break

pipes by pressing the pipes

excessively by a plier when

withdrawing the piping.

4

Provide a protective sheet

or a steel plate so that the

brazing flame can’t

influence the circumstance

around the four-way valve.

5

Heat up the four portions

of brazing parts on the

four-way valve. Remove

the four-way valve in the

order of (a),(b),(c),(d).

6

Heat up the blazing parts

and withdraw the pipes

connected to the four-way

valve by a plier and so on.

In case that the removal seems to

be hard;

1. Remove the piping connection

part(brazing part) easy to

remove and restore.

2. Cut the pipes on the main unit by

a miniature copper tube cutter in

order to make it easy to remove.

NOTE:

Don’t use a metal saw for cutting

pipes by all means because the

chips come into the circuit.

Step

Procedure

Points

Si-86.book Page 117 Friday, June 23, 2000 10:26 AM