SIE-86

Troubleshooting

Service Diagnosis

69

5.13

Operation Halt Due to Compressor Startup Error

(E6)

Remote Controller

Display

EEEE666

6

Indoor unit LED

Display

A

5

1

3

2

4

3

4

4

3

Method of

Malfunction

Detection

Compressor startup errors are detected using input current detected by CT and compressor’s operation

frequency.

Malfunction

Decision

Conditions

When the inlet current is over the setting value.

∗

Setting value = (145 / 256

∞

Output frequency) - 6 (A)

When a compressor startup error is generated 16 times consecutively, the system shuts down. (The 16

time counter resets itself when OL, insufficient gas or compressor startup error does not occur within 60

minutes of compressor operation time (cumulative time) after the error generation.)

Supposed Causes

Startup error due to faulty compressor.

Startup error due to faulty outdoor unit PCB.

Startup error due to closed stop valve.

Detection error due to faulty outdoor unit PCB.

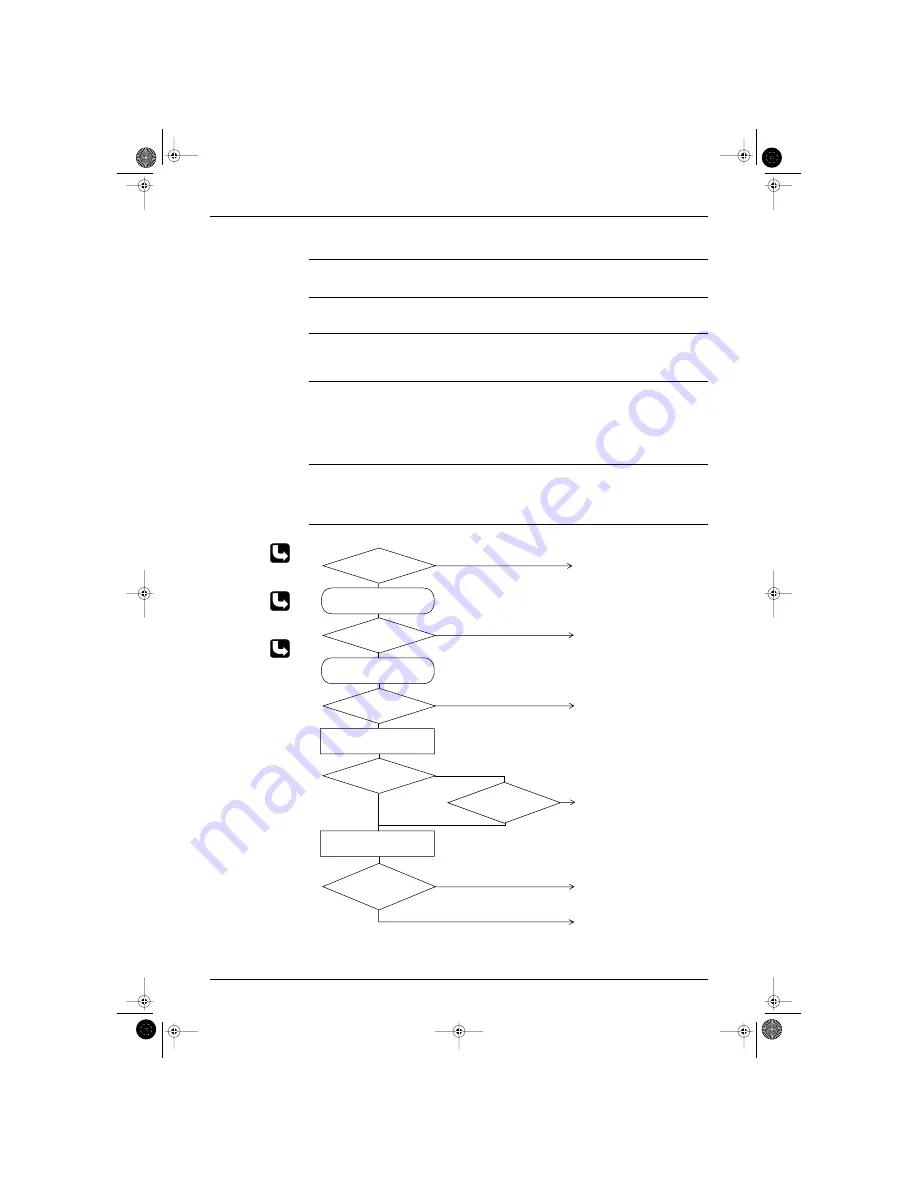

Troubleshooting

Check No.3

Refer to P.76

Check No.4

Refer to P.78

Check No.15

Refer to P.82

Check No. 3

Power transistor check

Is it normal?

Are the U, V

and W phases output in

good balance?

Does

the error occur

16 times consecutively,

causing system

shut-down?

Input current check.

Check No. 15

Compressor / refrigerant system

check

Input

current is over setting

value.

Is the stop valve open?

Check No. 4

Power transistor output check

Stop due to

compressor startup error

does not regenerate.

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

Open the stop valve fully.

Replace the outdoor PCB.

Check the harness, replace the

outdoor PCB.

Replace the outdoor unit PCB.

Clogging capillary tube and replace it.

Replace the compressor.

(MF012)

Si-86.book Page 69 Friday, June 23, 2000 10:26 AM