SiMX042215E

Troubleshooting

Part 6 Service Diagnosis

67

Reference

Troubleshooting

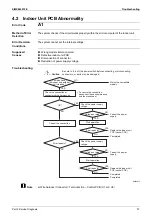

Check No.11

Refer to P.92

Check No.11

Check the po

w

er s

u

pply

w

a

v

eform.

Check the

v

oltage of the

connection

w

ires on the indoor

terminal strip

b

et

w

een

N

o. 1

and

N

o. 3, and

b

et

w

een

N

o. 2

and

N

o. 3.

YES

Blink

Replace the indoor

u

nit PCB

(control PCB).

Locate and eliminate the

ca

u

se of the dist

u

r

b

ance of

the po

w

er s

u

pply

w

a

v

eform.

N

O

(R24742)

Contin

u

o

u

sly O

N

or OFF

N

O

YES

YES

N

O

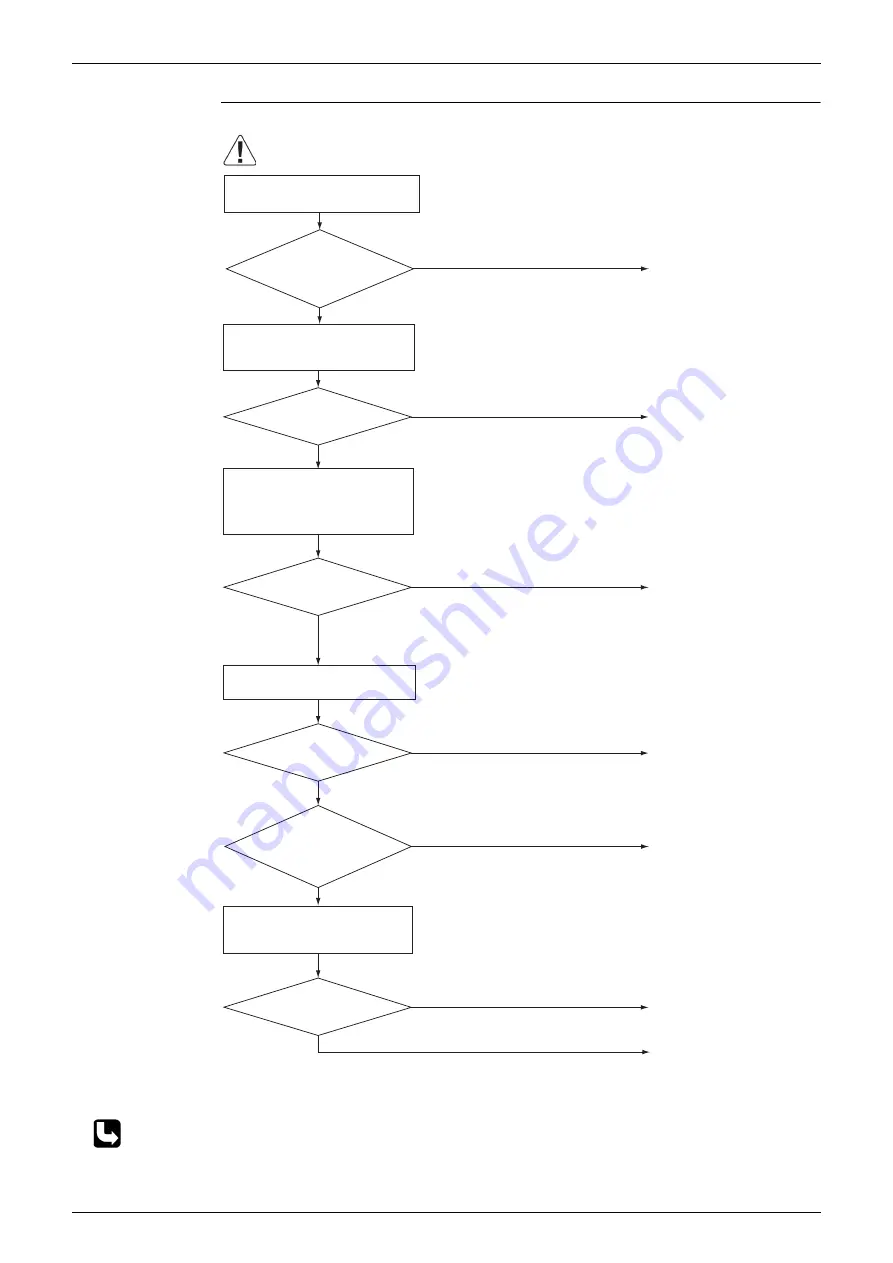

Caution

Correct the connection

w

ires

b

et

w

een the indoor

u

nit and

the o

u

tdoor

u

nit.

Replace the o

u

tdoor

u

nit PCB

(main PCB).

Replace the connection

w

ires

b

et

w

een the indoor

u

nit and

o

u

tdoor

u

nit.

Is LED A

b

linking?

Properly ins

u

lated?

Is there any dist

u

r

b

ance?

Is there any

w

iring error?

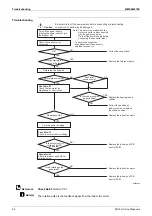

Check the connection

w

ires

b

et

w

een the indoor

u

nit and the

o

u

tdoor

u

nit.

Check the LED A on the o

u

tdoor

u

nit PCB.

Be s

u

re to t

u

rn off the po

w

er s

w

itch

b

efore connecting or disconnecting

connectors, or parts may

b

e damaged.

N

O

YES

Check the po

w

er s

u

pply

v

oltage.

Correct the po

w

er s

u

pply.

YES

N

O

Replace the o

u

tdoor fan motor

and the o

u

tdoor

u

nit PCB

(main PCB).

Rotate the

o

u

tdoor fan man

u

ally.

Does the o

u

tdoor fan rotate

smoothly?

Is the

v

oltage fl

u

ct

u

ation

w

ithin ±10% from the

rated

v

al

u

e?