Check

SiMX042215E

94

Part 6 Service Diagnosis

Caution

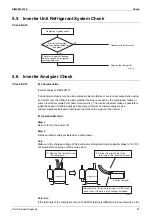

terminals), it is possible to connect wires available on site to the outdoor unit from output side of

PCB. (Do not connect them to the compressor at the same time, otherwise it may result in

incorrect detection.)

Step 3

Activate power transistor test operation from the indoor unit.

1. Turn the power on.

2. Select FAN operation with

MODE

button on the remote controller.

3. Press the center of

TEMP

button and

MODE

button at the same time.

4. Select

T

with

TEMP

up or

TEMP

down button.

5. Press

MODE

button to start the power transistor test operation.

Diagnose method (Diagnose according to 6 LEDs lighting status)

1. If all the LEDs are lit uniformly, the compressor is defective.

Replace the compressor.

2. If the LEDs are not lit uniformly, check the power module.

Refer to

Check No.22

.

3. If NG in

Check No.22

, replace the power module.

(Replace the main PCB. The power module is united with the main PCB.)

If OK in

Check No.22

, check if there is any solder cracking on the PCB.

4. If any solder cracking is found, replace the PCB or repair the soldered section.

If there is no solder cracking, replace the PCB.

1. When the output frequency is low, the LEDs blink slowly. As the output frequency increases,

the LEDs blink quicker. (The LEDs look like they are lit.)

2. On completion of the inverter analyzer diagnosis, be sure to re-crimp the FASTON terminals.

Otherwise, the terminals may be burned due to loosening.

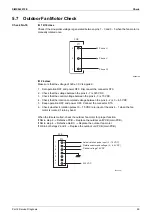

(R15292)

Direction of crimp

This size is shortened

b

y the crimp.

FASTO

N

terminal