Outdoor Unit

SiBE04-302

166

Removal Procedure

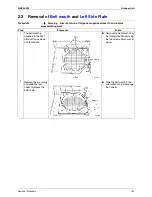

2.6

Removal of

Partition Plate

and

Reactor

Procedure

Warning Be sure to turn off all power supplies at least 10 min. before disassembling work.

Step

Procedure

Points

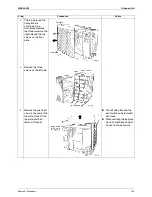

1. Remove the partition plate.

1

Remove the two

screws fixing the

partition plate.

2

Pull the partition plate

upward to remove.

Summary of Contents for FTKS25BVMB

Page 17: ...Functions SiBE04 302 8 List of Function...

Page 31: ...Specifications SiBE04 302 22 Specifications...

Page 137: ...Check SiBE04 302 128 Service Diagnosis...

Page 172: ...SiBE04 302 Outdoor Unit Removal Procedure 163 4 Remove the fan motor Step Procedure Points...

Page 184: ...SiBE04 302 Others 175 Part 8 Others 1 Others 176 1 1 Explanation 176 1 2 Jumper Settings 177...

Page 195: ...Wiring Diagrams SiBE04 302 186 Appendix...

Page 199: ...SiBE04 302 iv Index...