FTX-N/U, FVXS-N, FDMQ-R Series EDUS091558E

119

3P500432-1

CAUTION

•

To avoid the attached drain hose (2) getting excessive

force, do not bend nor twist it.

It may cause water leakage.

•

As for drain piping connection, do not connect the drain

hose directly to a sewage that gives off ammonia odor.

(The ammonia in the sewage may go through the drain

piping and corrode the heat exchanger of the indoor unit.)

•

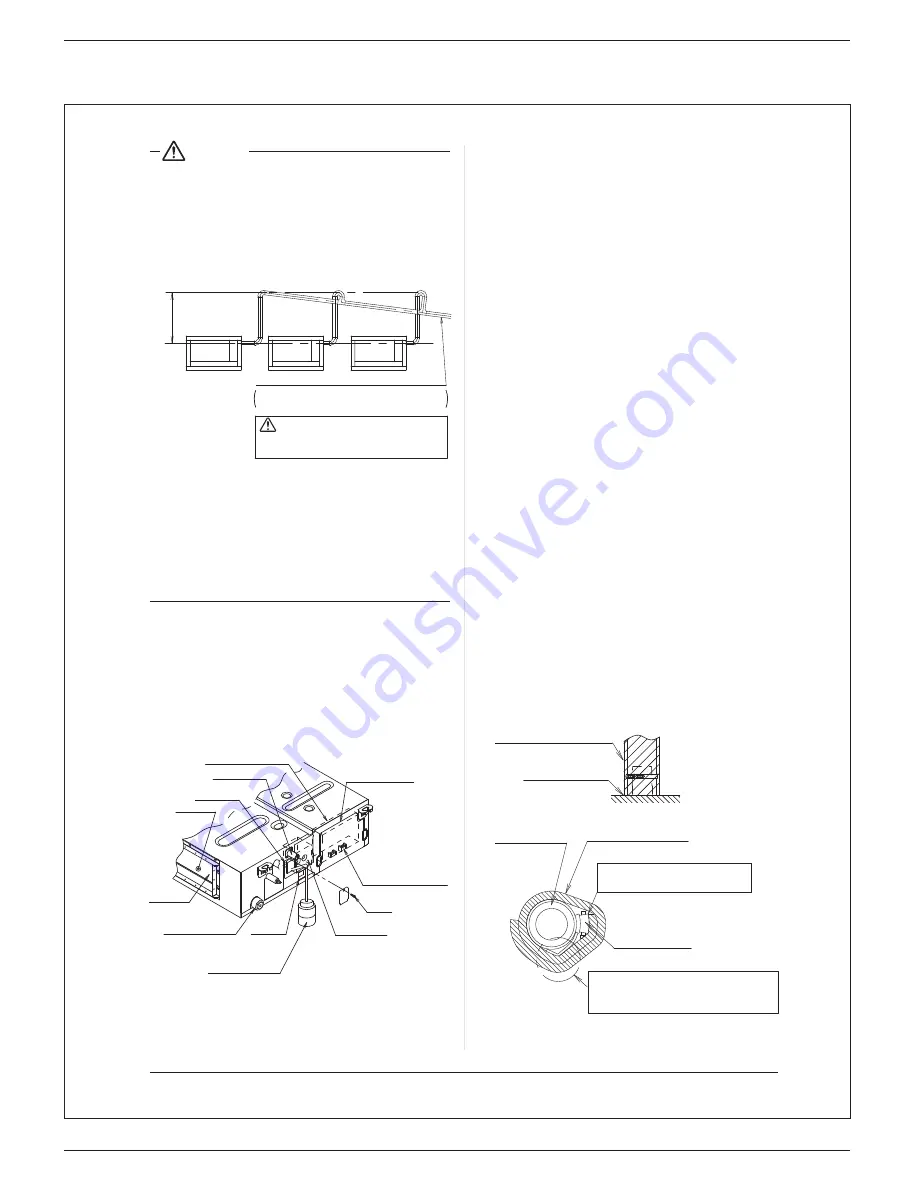

In case of centralized drain piping, carry out piping work

according to the procedure shown in the fol lowing

Fig. 16

.

Make a downward inclination of 1/100 or

more to avoid stagnation of air.

If water stagnates in the drain

piping, it may cause clogging of

drain piping.

29-9/16 inch

(675mm)

Centralized drain piping

Fig. 16

•

As for the size of centralized drain piping, select the size

that meets the capacity of indoor units to be con nected.

(Refer to the technical document)

•

Positioning the upward drain piping at an angle may cause

float switch malfunction and lead to water leakage.

•

While replacing with new indoor unit, use the attached

new drain hose (2) and the clamp metal (1).

If an old drain hose or a clamp metal is used, it may

cause water leakage.

(2)

After piping work is finished, check if drainage flows

smoothly.

[When the electric wiring work is finished]

•

Gradually pour 1/4 gal of water from the inspection

port at the bottom of the drain socket on the left side

of the drain socket into the drain pan giving caution to

avoid splashing water on the electric components such

as drain pump and confirm drainage by operating the

indoor unit under cooling mode according to

10. FIELD SETTING

.

(Refer to Fig. 17)

Electrical wiring box

Drain socket

Filling port

Drain pan

Socket for

maintenance

(with rubber cap)

Plastic container

for pouring water

Drain pump

position

Terminal block

for wiring between

the indoor and

outdoor units

Electrical wiring

box cover

Air outlet

Access

window

Screw

[Method of adding water]

Fig. 17

[When the electric wiring work is not finished]

•

The electric wiring works (including grounding) must be

carried out by a qualified electrician.

•

If a qualified person is not present, after the electric

wiring work is finished, check the drainage accord ing

to the method specified in

[When the electric wiring

work is finished]

.

1.

Open the electrical wiring box cover and connect the

ground wiring to the ground terminal.

2.

Make sure the electrical wiring box cover is closed

before turning on the power supply.

•

Throughout the whole process, carry out the work

giving caution to the wiring around the electrical

wiring box so that the connectors may not come

off.

3.

Gradually pour 1 litre of water from the air outlet on

the left side of the drain socket into the drain pan

giving caution to avoid splashing water on the electric

components such as drain pump.

(Refer to Fig. 17)

4.

When the power supply is turned on, the drain

pump will operate. Drainage can be checked at the

transparent part of the drain socket.

(The drain pump will automatically stop after 10

minutes.)

The drainage of water can be confirmed with water level

change in the drain pan through the access window.

•

Do not connect the drain piping directly to the

sewage that gives off ammonia odor.

The ammonia in the sewage may go through the

drain piping and corrode the heat exchanger of the

indoor unit.

•

Do not apply external force to the float switch. (It

may result in malfunction)

•

Do not touch the drain pump.

Touching the drain pump may cause electric shock.

5.

Turn off the power supply after checking drainage,

and remove the power supply wiring.

6.

Attach the electrical wiring box cover as before.

(3) Sweating may occur and result in water leakage.

Therefore, make sure to insulate the following

2 locations (drain piping that laid indoors and drain

sockets).

•

Use the provided sealing pad (large) (6), and perform

the thermal insulation of the clamp metal (1) and drain

hose (2) after checking the drainage of water.

(Refer to

Fig. 18)

Start wrapping from where the

clamp metal (1) is tightened.

Wrap the sealing pad (Large) (6) so that

the clamp metal (1) end side may be

doubled.

Clamp metal (1)

Drain hose (2)

Sealing pad (Large) (6)

Sealing pad (Large) (6)

No clearance is

allowed.

Unit

Fig. 18

10

01_EN_3P500432-1.indd 10

10/24/2017 18:32:34

Summary of Contents for FTX-N/U

Page 1: ...Heat Pump Split Type Air Conditioners FTX N U FVXS N FDMQ R Series EDUS091558E...

Page 2: ......

Page 17: ...FTX N U FVXS N FDMQ R Series EDUS091558E 15 C 3D123383 FTX24UVJU C 3D123379 FTX18UVJU...

Page 19: ...FTX N U FVXS N FDMQ R Series EDUS091558E 17 3D112919B FDMQ18 24RVJU 3D112918B FDMQ12RVJU...

Page 20: ...18 FTX N U FVXS N FDMQ R Series EDUS091558E 3D049611A BRC082A43 C 3D091305A BRC1E73...

Page 22: ...20 FTX N U FVXS N FDMQ R Series EDUS091558E 3D107983A RXL24UMVJUA 3D123362 RXL18UMVJUA...

Page 25: ...FTX N U FVXS N FDMQ R Series EDUS091558E 23 3D112629A FDMQ12 18 24RVJU...

Page 32: ...30 FTX N U FVXS N FDMQ R Series EDUS091558E 3D107985A RXL24UMVJUA...

Page 59: ...FTX N U FVXS N FDMQ R Series EDUS091558E 57 3D113126 FDMQ18RVJU...

Page 60: ...58 FTX N U FVXS N FDMQ R Series EDUS091558E 3D113128 FDMQ24RVJU...

Page 62: ...60 FTX N U FVXS N FDMQ R Series EDUS091558E 3D113129 FDMQ24RVJU...

Page 65: ...FTX N U FVXS N FDMQ R Series EDUS091558E 63 3D123455 FTX18UVJU 3D100354 FTX15NMVJU...

Page 66: ...64 FTX N U FVXS N FDMQ R Series EDUS091558E 3D094737 FVXS09NVJU 3D074866A FTX24UVJU...

Page 67: ...FTX N U FVXS N FDMQ R Series EDUS091558E 65 3D094777A FVXS15NVJU 3D094766 FVXS12NVJU...

Page 70: ...68 FTX N U FVXS N FDMQ R Series EDUS091558E 3D123453 RXL18UMVJUA 3D100636 RXL15QMVJUA...

Page 71: ...FTX N U FVXS N FDMQ R Series EDUS091558E 69 3D123454 RXL24UMVJUA...

Page 394: ...392 FTX N U FVXS N FDMQ R Series EDUS091558E 1P124687 1A...

Page 395: ...FTX N U FVXS N FDMQ R Series EDUS091558E 393 1P124687 1A...

Page 396: ...394 FTX N U FVXS N FDMQ R Series EDUS091558E 1P124687 1A...

Page 397: ...FTX N U FVXS N FDMQ R Series EDUS091558E 395 1P124687 1A...

Page 401: ...FTX N U FVXS N FDMQ R Series EDUS091558E 399 3P124623 1E 4 Fig 6 Fig 5 Fig 8 Fig 7...

Page 412: ...410 FTX N U FVXS N FDMQ R Series EDUS091558E 3P124623 1E 15...

Page 422: ...420 FTX N U FVXS N FDMQ R Series EDUS091558E 3P124623 1E 25 Fig 9 Fig 12 Fig 10 Fig 11...

Page 423: ...FTX N U FVXS N FDMQ R Series EDUS091558E 421 3P124623 1E 26 Fig 14 Fig 13 Fig 16 Fig 15...

Page 425: ...FTX N U FVXS N FDMQ R Series EDUS091558E 423 1P126474 1B...

Page 426: ...424 FTX N U FVXS N FDMQ R Series EDUS091558E 1P126474 1B...

Page 427: ...FTX N U FVXS N FDMQ R Series EDUS091558E 425 1P126474 1B...

Page 428: ...426 FTX N U FVXS N FDMQ R Series EDUS091558E 1P126474 1B...

Page 433: ...FTX N U FVXS N FDMQ R Series EDUS091558E 431 3P162015 1A...

Page 434: ...432 FTX N U FVXS N FDMQ R Series EDUS091558E 3P162015 1A...

Page 435: ...FTX N U FVXS N FDMQ R Series EDUS091558E 433 3P162015 1A...

Page 436: ...434 FTX N U FVXS N FDMQ R Series EDUS091558E 3P162015 1A...

Page 455: ...FTX N U FVXS N FDMQ R Series EDUS091558E 453 3P400464 1...

Page 457: ...FTX N U FVXS N FDMQ R Series EDUS091558E 455 3P561172 1...

Page 459: ...FTX N U FVXS N FDMQ R Series EDUS091558E 457 3P534932 1B...

Page 469: ...FTX N U FVXS N FDMQ R Series EDUS091558E 467 3P436077 1...

Page 471: ...FTX N U FVXS N FDMQ R Series EDUS091558E 469 3P436078 1...

Page 472: ...470 FTX N U FVXS N FDMQ R Series EDUS091558E 3P436079 1 14 26 KPS067A44 Snow Hood Outlet...

Page 473: ...FTX N U FVXS N FDMQ R Series EDUS091558E 471 3P436079 1...

Page 475: ...FTX N U FVXS N FDMQ R Series EDUS091558E 473 3P436071 1...

Page 477: ...FTX N U FVXS N FDMQ R Series EDUS091558E 475 3P436072 1...

Page 478: ...476 FTX N U FVXS N FDMQ R Series EDUS091558E 3P436073 1 14 29 KPS063A47 Snow Hood Outlet...

Page 479: ...FTX N U FVXS N FDMQ R Series EDUS091558E 477 3P436073 1...

Page 480: ...478 FTX N U FVXS N FDMQ R Series EDUS091558E...

Page 481: ......

Page 482: ......

Page 483: ......