English

16

English

Refrigerant Piping Work

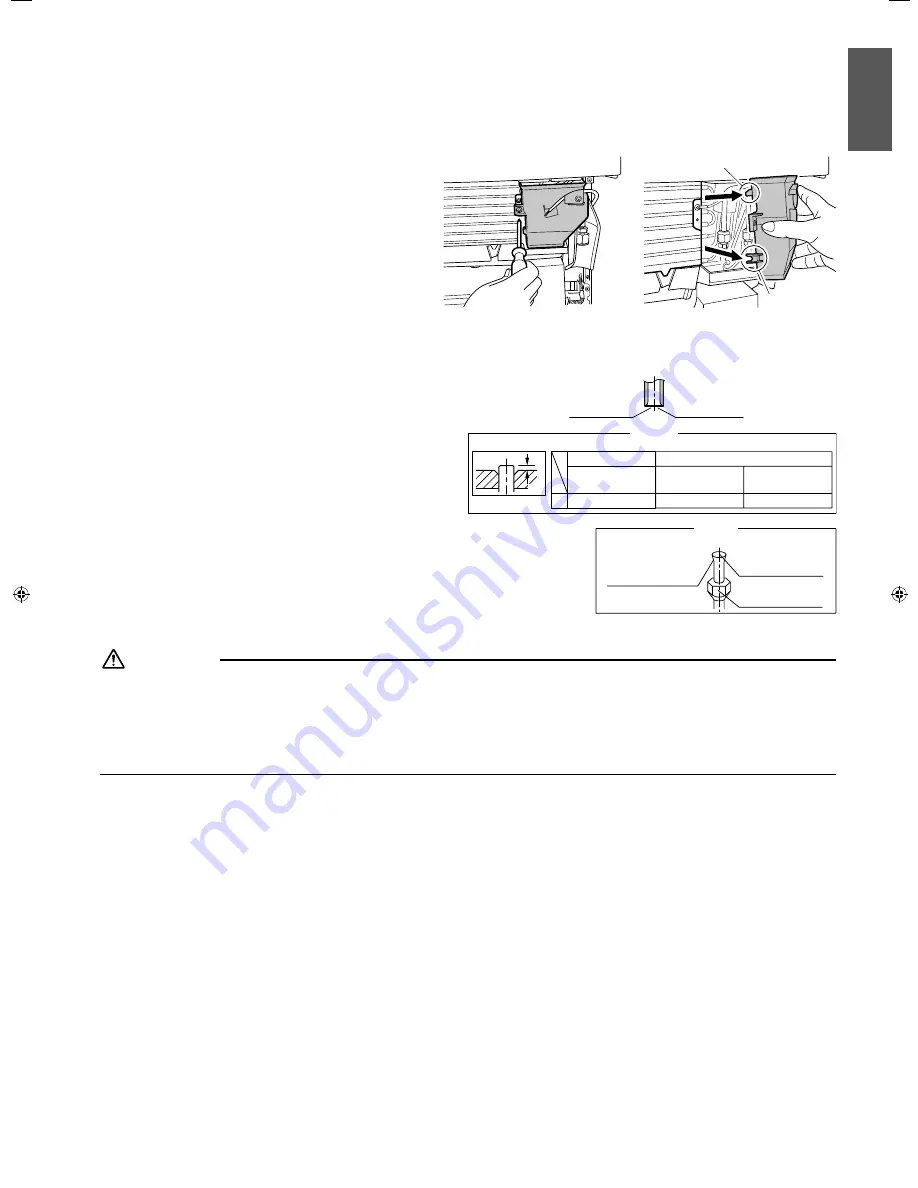

Removing the drip proof cover

1.

Take out 1 screw and remove the drip proof cover.

•

Hook

Tab

Use the holding tape attached to the unit to temporarily

fi

x the drip proof cover to the side of the unit.

•

Flaring the pipe end

2.

Cut the pipe end with a pipe cutter.

1)

Remove burrs with the cut surface facing down-

2)

ward so that the chips do not enter the pipe.

Put the

fl

are nut on the pipe.

3)

Flare the pipe.

4)

Check that the

fl

aring is properly made.

5)

A

A

(Cut exactly at

right angles.)

Remove burrs.

Flaring

Set exactly at the position shown below.

Die

0-0.5mm

Clutch-type

Flare tool for R410A

1.0-1.5mm

Clutch-type

(Rigid-type)

1.5-2.0mm

Wing-nut type

(Imperial-type)

Conventional flare tool

Flare’s inner surface

must be flaw-free.

The pipe end must

be evenly flared in

a perfect circle.

Make sure that the

flare nut is fitted.

Check

WARNING

Do not use mineral oil on

fl

ared part.

•

Prevent mineral oil from getting into the system as this would reduce the lifetime of the units.

•

Never use piping which has been used for previous installations. Only use parts which are delivered with the unit.

•

Do never install a drier to this R410A unit in order to guarantee its lifetime.

•

The drying material may dissolve and damage the system.

•

Incomplete

fl

aring may cause refrigerant gas leakage.

•

01_EN_3P276870-1.indb 16

01_EN_3P276870-1.indb 16

2/23/2011 5:04:23 PM

2/23/2011 5:04:23 PM