FXDQ-SPV1 EDTFVN391825

30

3P347455-11H

5

(4) Tighten the nut on the upper side.

CAUTION

·

Please use a water level or water filled polyethylene

pipe to confirm whether the air conditioner is installed

horizontally. When a polyethylene pipe is used to replace

a water level, please align the upper surface of the product

with the horizontal level of both sides of the polyethylene

pipe, so as to adjust the level of the product.

(Please

pay special attention to note that the tilting direction

shall not be reversed against the water drainage

direction, as this will result in water leakage.)

Water level

Polyethylene pipe

6. REFRIGERANT PIPING WORK

(For the installation of the refrigerant pipe for the

outdoor unit, please refer to the installation manual for

the outdoor unit.)

(Heat insulation shall be carried out for the pipes on

the air supply side and the liquid side. Otherwise water

may leak out. Please use insulation material which can

withstand a high temperature of over 120

o

C.

Please base on the installation environment to reinforce

the heat insulation for the refrigerant pipe.

Otherwise, condensate may occur on the surface of the

heat insulation material.)

(Before installing the refrigerant pipe, please always

confirm that the refrigerant is R410A. In case that any

other refrigerant is used, the air conditioner cannot work

normally.)

The product is a special machine using new type

refrigerant (R410A). Please always comply with the

following items to carry out the installation work.

·

Use special pipe cutting machine and flare tools for R410A.

·

When connecting the flare, please apply freezing oil

(ester oil or ether oil) only on the inside of the flare.

·

Always use the flare nut supplied with the air conditioner.

(Never use flare nut of any other type, such as Type 1

flare nut, otherwise the refrigerant may leak out.)

·

To prevent dirt, dust or moisture from entering into the

inside of the pipe, please correct the pipe in the

squeezed or sealed manner.

CAUTION

CAUTION

·

Please ensure to use refrigerant of the specified type in

the refrigeration cycle, and never let the air contaminate

the refrigerant.

·

In case that during installation any refrigerant is leaked

out, the house should be ventilated for air exchange.

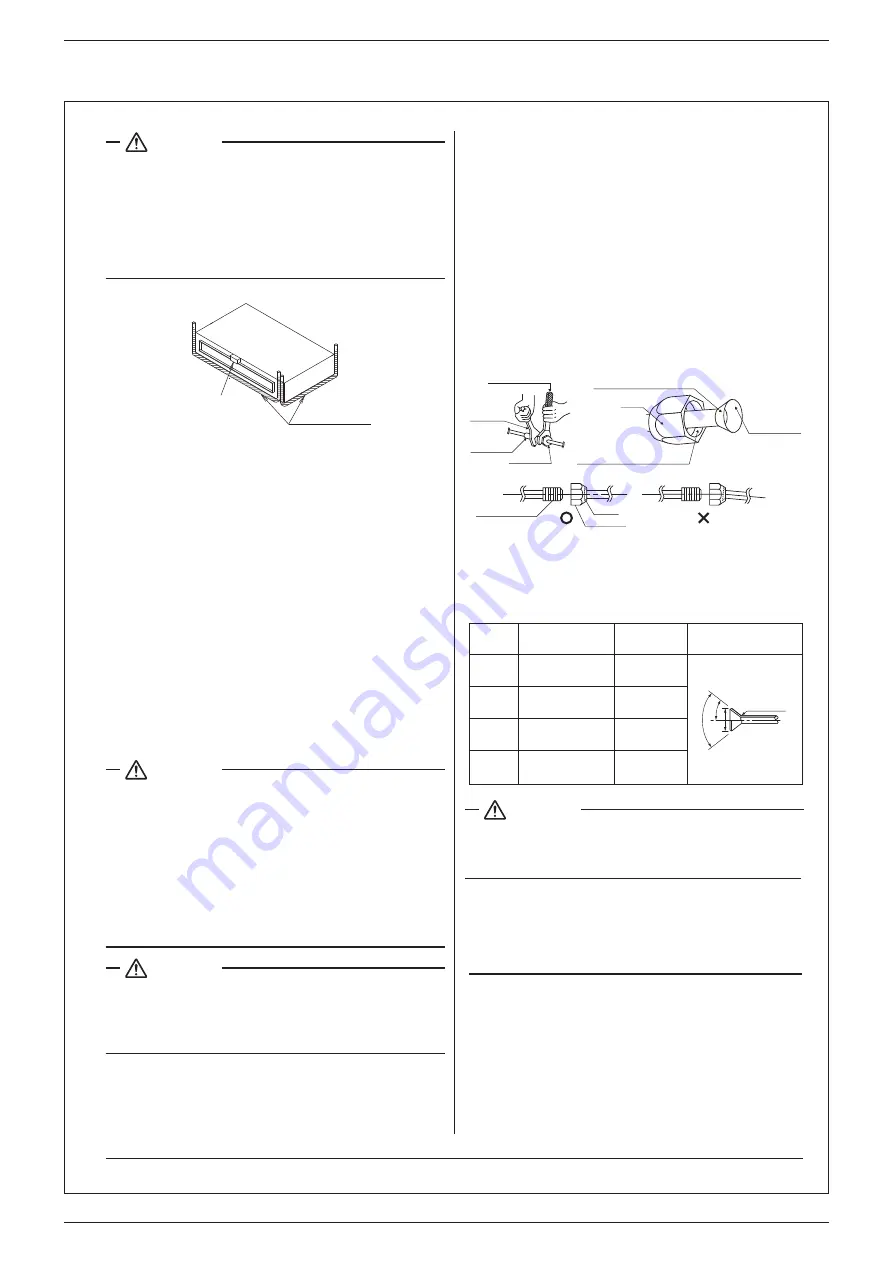

(1) Connect the pipe.

·

Refrigerant has been filled in the outdoor unit.

·

Align the connecting section of the refrigerant pipe to

the center of the flare section, and firstly turn 3 – 4

operations manually, and then tighten the pipe with the

specified torque.

·

To prevent the flare section from being broken or

leaking air, please tighten with a torque wrench.

(Please refer to Fig. 6)

·

To prevent air leakage, please apply freezing oil

(ester oil or ether oil) on the inside of the flare.

(Please refer to Fig. 7)

·

Please fix the flare nut to the main unit. (To prevent the

flare nut from aging and cracking)

·

For the dimensions of the flare and the tightening torque,

please refer to Table 1.

[Applying oil]

[Tightening]

Torque wrench

Wrench

Pipe

connector

Flare nut

Fig. 6

Fig. 7

Never apply the freezing

oil on the outer surface

Apply the

freezing oil

on the inner

surface of

the flare

Nut

Never let the nut in

contact with the freezing oil,

and avoid over-tightening

Pipe connector

Flare

Flare nut

Note : Please always align the center of the connection

section of the refrigerant pipe with the center of the flare

section and the flare nut.

Otherwise pipe breaking or air leakage can occur.

A

Table 1

Pipe

diameter

Tightening torque

Flare dimension

A (mm)

Flare

Ø 6.4

(1/4”)

Ø 9.5

(3/8”)

Ø 12.7

(1/2”)

Ø 15.9

(5/8”)

14.2 - 17.2N

•

m

(144 - 176 kgf

•

cm)

32.7 - 39.9N

•

m

(333 - 407 kgf

•

cm)

49.5 - 60.3N

•

m

(504 - 616 kgf

•

cm)

61.8 - 75.4N

•

m

(630 - 770 kgf

•

cm)

8.7 - 9.1

12.8 - 13.2

16.2 - 16.6

19.3 - 19.7

R0.4-0.8

90°±2°

45°±2°

CAUTION

Over-tightening can damage the flare and result in

refrigerant leakage. Please note not to let oil stick

to any part outside the flare. In case that any oil

sticks to parts as resin, damage can occur.

·

In case that a torque wrench is not available, please

refer to Table 2.

When an ordinary wrench is used to tighten the flare nut,

the nut will suddenly become tightened in some point.

From such point, further tighten the nut to the angle as

shown in Table 2.

It is not recommended to use this method, and it can

be used only in emergency cases.

You must use a torque wrench, but if you do not have a

torque wrench and have to install the unit, you can follow

the following method to install.

When you complete the work, always check whether

any air is leaked out.

When you use a wrench to tighten the flare nut, the

tightening torque can suddenly increase in some point.

From such point, further tighten the flare nut to the angle

as shown below :

Summary of Contents for FXDQ-SPV1

Page 1: ...FXDQ SPV1 EDTFVN391825 201803 Engineering Data 50 Hz...

Page 2: ......

Page 8: ...FXDQ SPV1 EDTFVN391825 6 3 Dimensions FXDQ20SPV1 FXDQ25SPV1 FXDQ32SPV1 3D071829D Unit mm...

Page 9: ...FXDQ SPV1 EDTFVN391825 7 FXDQ40SPV1 FXDQ50SPV1 3D071831D Unit mm...

Page 10: ...FXDQ SPV1 EDTFVN391825 8 FXDQ63SPV1 3D071830D Unit mm...

Page 17: ...FXDQ SPV1 EDTFVN391825 15 9 Fan Performances FXDQ20SPV1 3D072697C...

Page 18: ...FXDQ SPV1 EDTFVN391825 16 FXDQ25SPV1 3D072698C...

Page 19: ...FXDQ SPV1 EDTFVN391825 17 FXDQ32SPV1 3D090527...

Page 20: ...FXDQ SPV1 EDTFVN391825 18 FXDQ40SPV1 FXDQ50SPV1 3D072702C...

Page 21: ...FXDQ SPV1 EDTFVN391825 19 FXDQ63SPV1 3D090542...

Page 22: ...FXDQ SPV1 EDTFVN391825 20 10 Sound Levels FXDQ20SPV1 FXDQ25SPV1 4D090507A 4D090508A...

Page 23: ...FXDQ SPV1 EDTFVN391825 21 FXDQ32SPV1 FXDQ40SPV1 FXDQ50SPV1 4D090509A 4D090510A...

Page 24: ...FXDQ SPV1 EDTFVN391825 22 FXDQ63SPV1 4D090511A...

Page 26: ...FXDQ SPV1 EDTFVN391825 24 FXDQ63SPV1 4D072720H Unit mm...

Page 41: ......

Page 42: ......

Page 43: ......